Bridging type metal bipolar plate

A metal bipolar plate, bridge-type technology, applied in the direction of fuel cells, electrochemical generators, electrical components, etc., can solve the problems of affecting bipolar plate assembly, uneven acceptance, affecting gas distribution, etc., and optimize the gas flow channel. Design, stable position, and the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

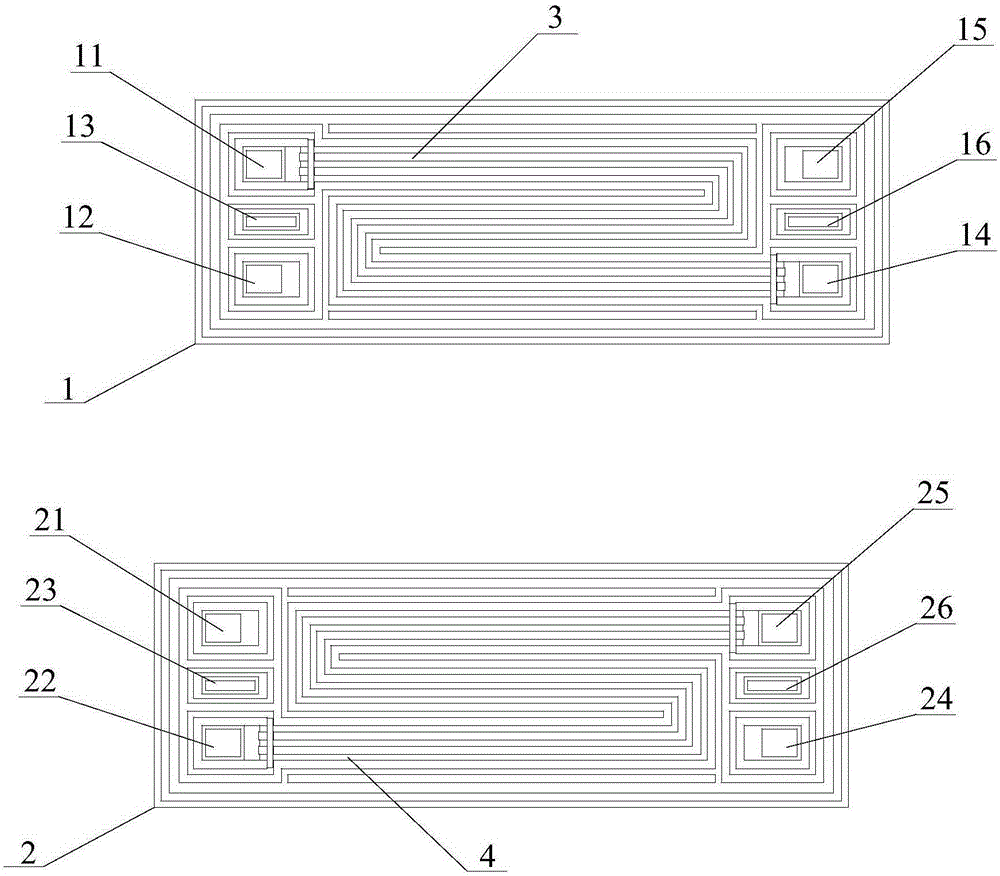

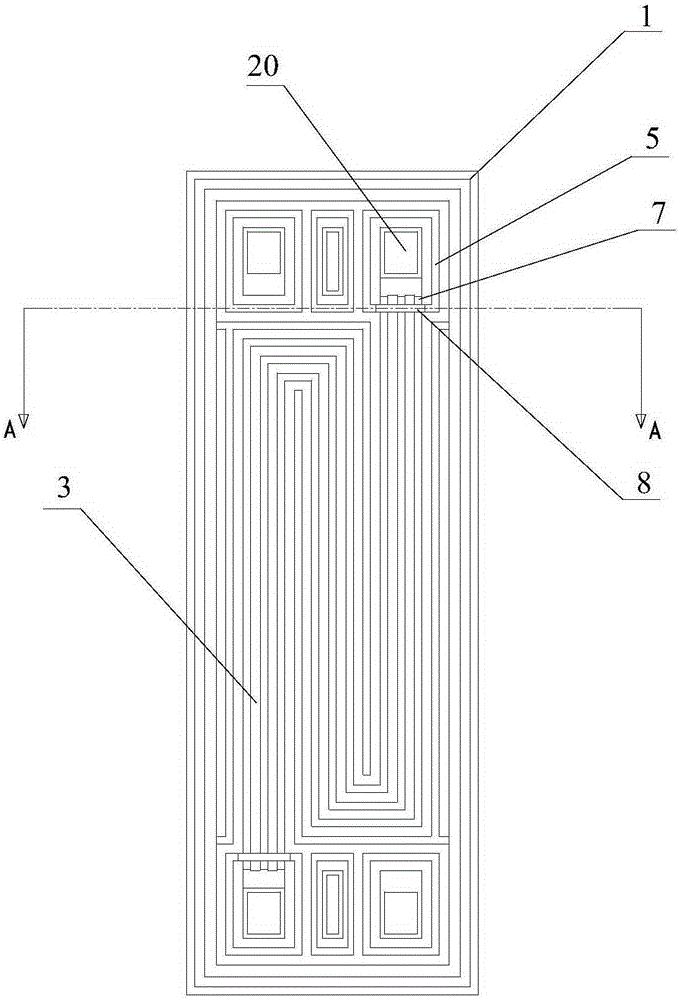

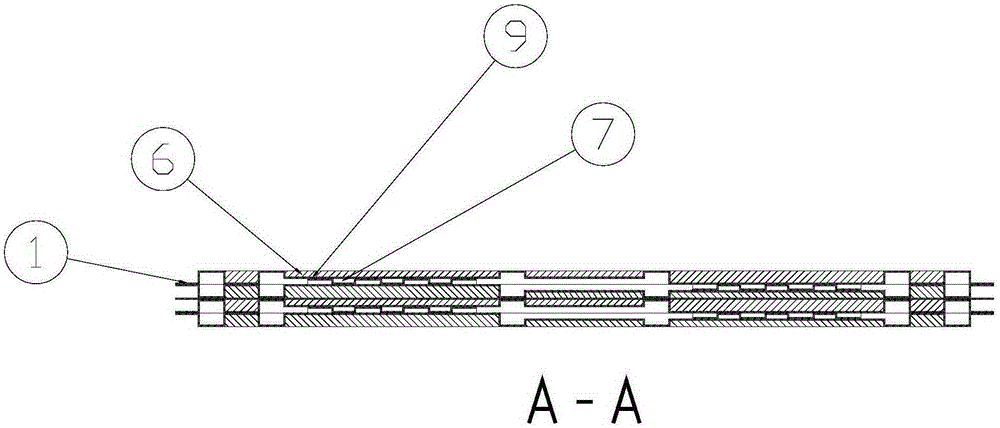

[0026] Example 1: A bridge type metal bipolar plate, comprising a stamped and formed oxygen plate 1 and a hydrogen plate 2. Both sides of the oxygen plate 1 and hydrogen plate 2 are respectively stamped with oxidant gas inlets 11, 21, fuel gas inlets 12, 22, and cooling Liquid inlets 13, 23 and oxidant gas outlets 14, 24, fuel gas outlets 15, 25, and coolant outlets 16, 26; oxygen plate 1 and hydrogen plate 2 are stacked, and each inlet and outlet 11, 12, and 13, 14, 15, 16 and each of the inlet and outlet 21, 22, 23, 24, 25, 26 of the hydrogen plate are connected up and down one by one. The grooves on the front of the hydrogen plate 2 and the oxygen plate 1 are distributed on the surfaces of the two plates. The hydrogen plate gas flow field 4 and the oxygen plate gas flow field 3 are formed. The oxygen plate gas flow field 3 is an S-shaped anode gas flow field, and the hydrogen plate gas flow field 4 is an S-shaped cathode gas flow field. The anode gas flow field and The cat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com