A low-profile double-layer printed ultra-wideband antenna with multiple backstrips to expand the frequency band

An ultra-wideband antenna and low-profile technology, applied to antennas, devices that enable antennas to work in different bands at the same time, electrical components, etc., can solve the problems of high profile, complex processing, and inflexible application, and achieve high gain and simple processing , the effect of increasing the degree of freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

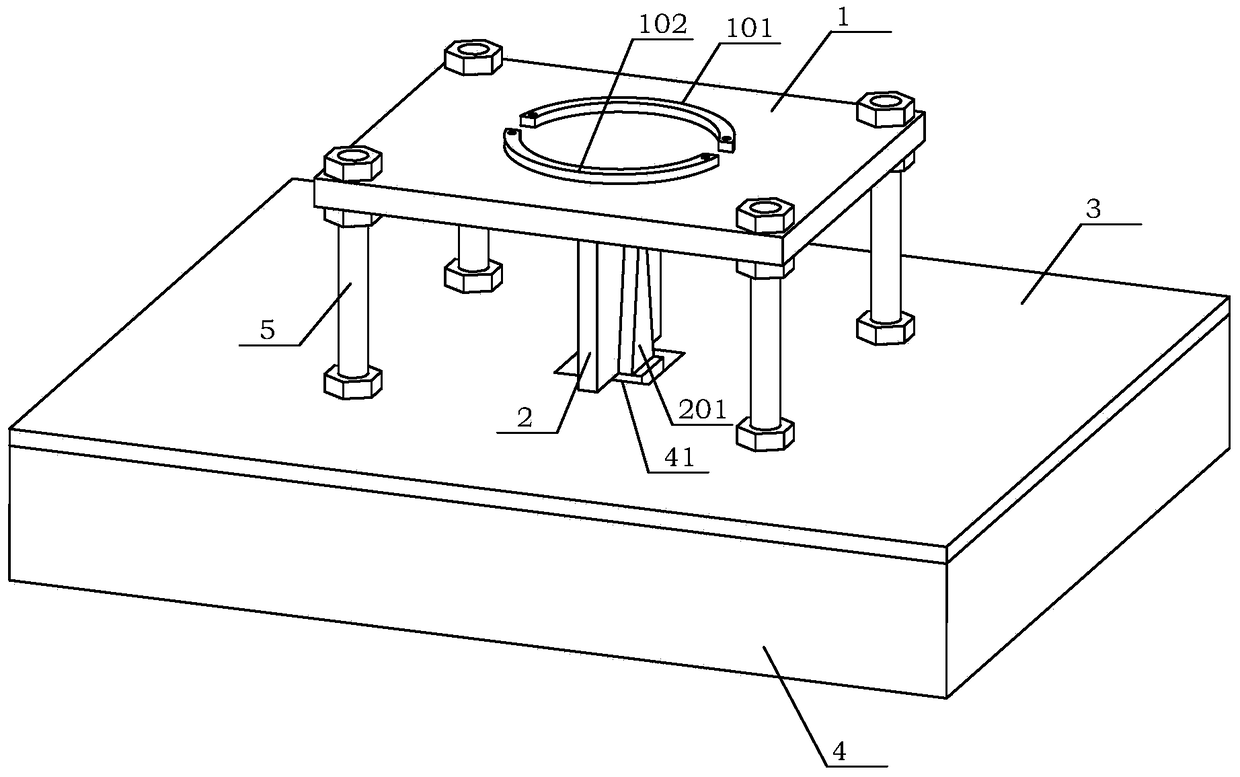

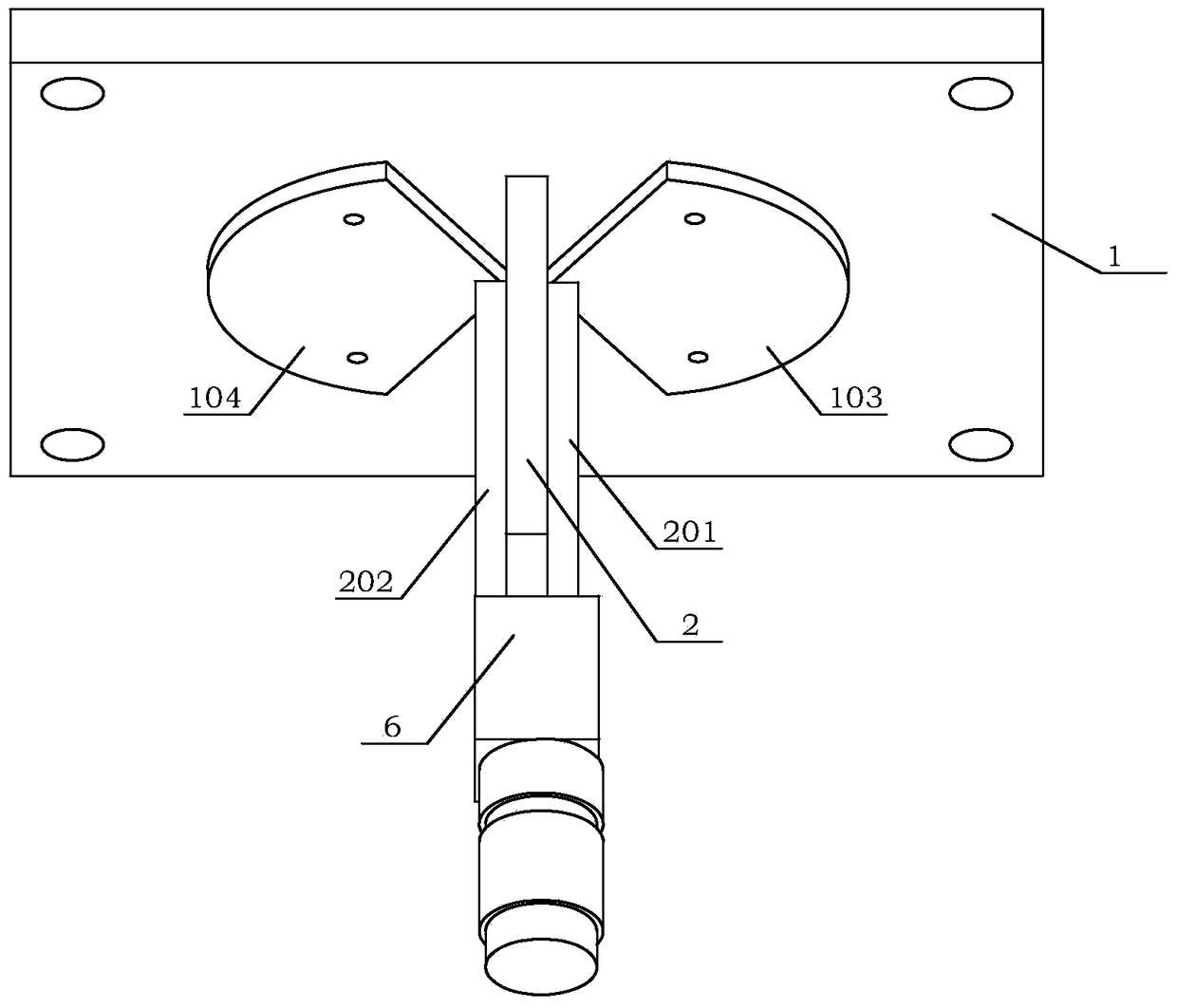

[0059] Low-profile double-layer printed UWB antenna structure with single backstrip:

[0060] see figure 2 , Figure 2A , Figure 2B As shown, AA back strips 1A1 are processed on the upper surface 11 of the transverse dielectric board 1 using the copper-clad technology, and the first vibrator 121 and the The second vibrator 122 .

[0061] Horizontal media board 1:

[0062] see figure 1 , Figure 1A , Figure 1B , figure 2 , Figure 2A As shown, the transverse dielectric plate 1 is a rectangular structure, the length of the transverse dielectric plate 1 is denoted as E, and the width is denoted as D, and .

[0063] The upper surface 11 of the transverse dielectric board 1 is provided with an arc-shaped groove having the same configuration as the AA back strip 1A1 , and the arc-shaped groove is coated with copper material using copper cladding technology to form the AA back strip 1A1 . The structure of setting arc-shaped grooves on the upper surface 11 of the trans...

Embodiment 2

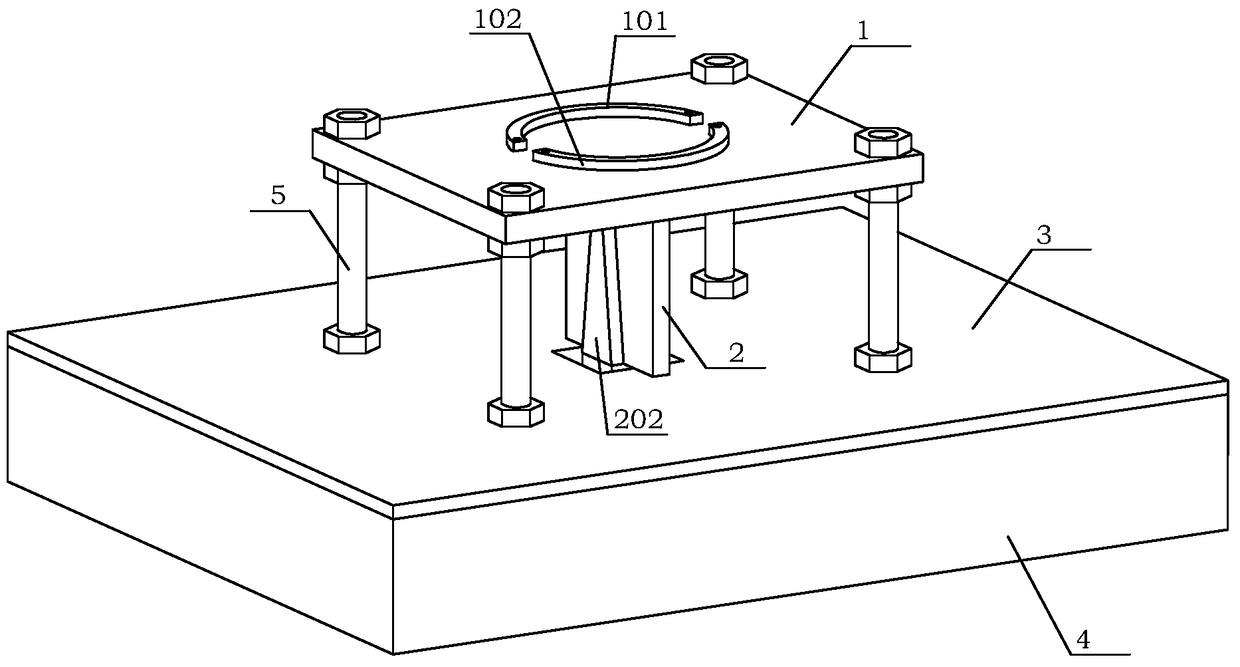

[0083] Low-profile double-layer printed ultra-wideband antenna structure with double backstrips:

[0084] see image 3 , Figure 3A , Figure 3B As shown, BA back strips 1B1 and BB back strips 1B2 are processed on the upper board surface 11 of the transverse dielectric board 1 using copper-clad technology, and the same structure is processed on the lower board surface 12 of the transverse dielectric board 1 using copper-clad technology. The first vibrator 121 and the second vibrator 122 .

[0085] Horizontal media board 1:

[0086] see figure 1 , Figure 1A , Figure 1B , image 3 , Figure 3A As shown, the transverse dielectric plate 1 is a rectangular structure, the length of the transverse dielectric plate 1 is denoted as E, and the width is denoted as D, and

[0087] The upper plate surface 11 of the transverse dielectric plate 1 is provided with a BA arc-shaped groove having the same configuration as the BA back bar 1B1 and a BB arc-shaped groove having the sam...

Embodiment 3

[0109] Low-profile double-layer printed UWB antenna structure with three back strips:

[0110] see Figure 4 , Figure 4A , Figure 4B As shown, CA back strips 1C1, CB back strips 1C2, and CC back strips 1C3 are processed on the upper board surface 11 of the transverse dielectric board 1 using copper clad technology, and copper clad technology is used on the lower board surface 12 of the transverse dielectric board 1 A first vibrator 121 and a second vibrator 122 with the same structure are processed.

[0111] Horizontal media board 1:

[0112] see figure 1 , Figure 1A , Figure 1B , Figure 4 , Figure 4A As shown, the transverse dielectric plate 1 is a rectangular structure, the length of the transverse dielectric plate 1 is denoted as E, and the width is denoted as D, and

[0113] The upper plate surface 11 of the transverse medium plate 1 is provided with a CA arc-shaped groove having the same configuration as the CA back strip 1C1, a CB arc-shaped groove havin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com