Switch cabinet forced ventilation dehumidification system

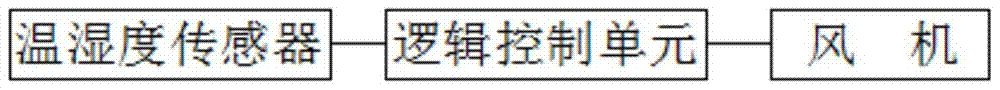

A forced ventilation and switchgear technology, applied in the cooling/ventilation of substation/switchgear, substation/switch layout details, electrical components, etc. Achieve economical and cheap system transformation, ensure normal operation, and achieve obvious effects of dehumidification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

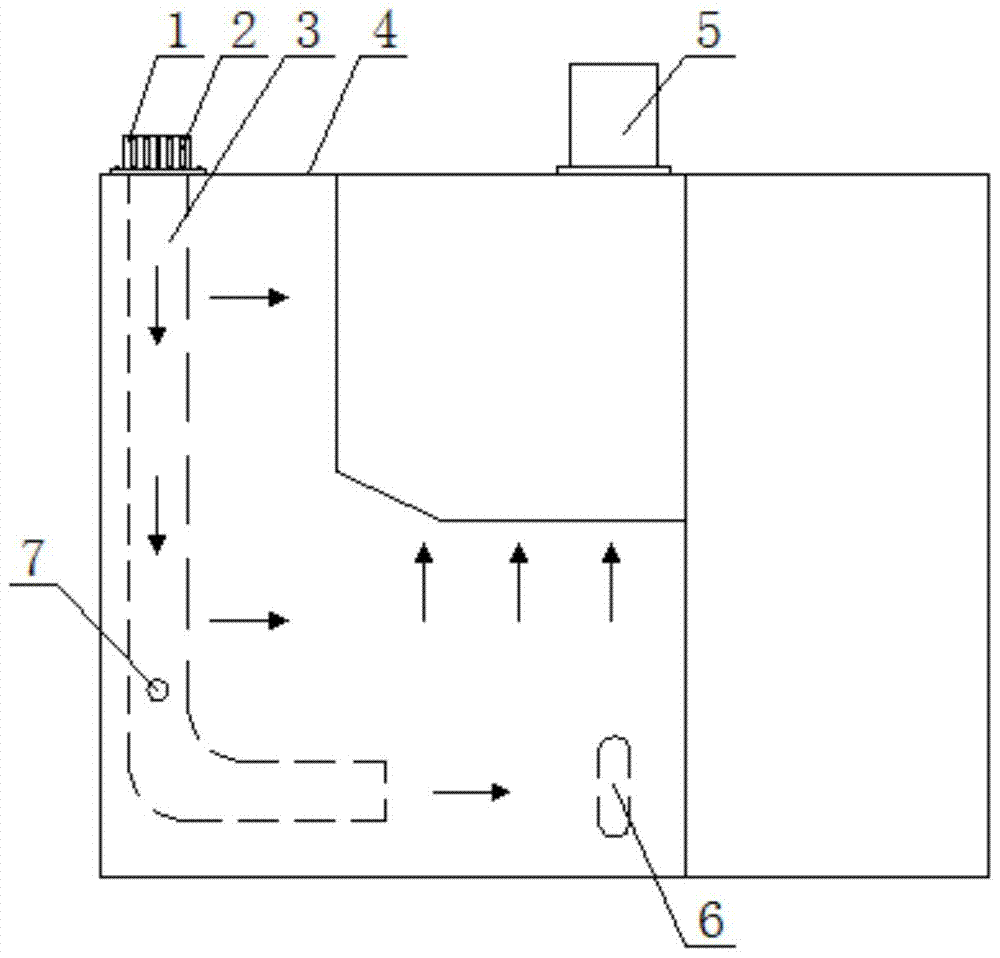

[0022] The following describes the embodiments of the present invention in detail with reference to the accompanying drawings; it should be noted that this embodiment is narrative and not restrictive, and the protection scope of the present invention cannot be limited by this.

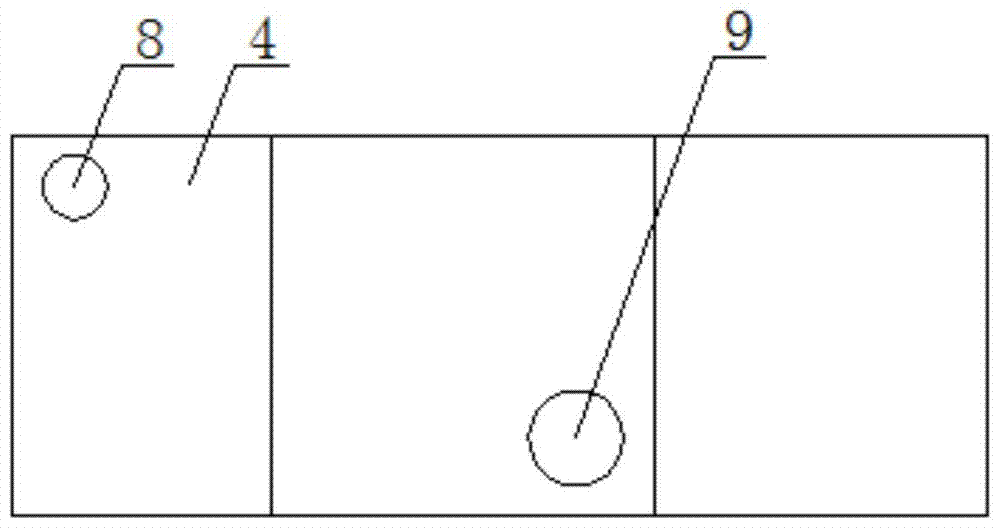

[0023] A forced ventilation and dehumidification system for a switch cabinet, including a cabinet body 4, a tuyere 8, a ventilation duct 3 and a fan system. A tuyere is made on the top plate of the cabinet body. The tuyere is a circular opening with a diameter of 100mm to ensure ventilation. The need for traffic. A square metal cap 1 is set above the air outlet. The four sides of the square metal cap are provided with rectangular vertical strip holes 2. Each hole is 100mm long and 1mm wide, and there are fixing bolts and holes on the edge. The square metal cap covers the circle. Above the opening, it is fixed to the top plate by bolts.

[0024] The air outlet is connected to a ventilation duct located in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com