Color response testing and correcting device and method for industrial color cameras

A color camera, color response technology, applied in TV, electrical components, image communication, etc., can solve problems such as deviation, achieve the effect of accurate correction, ensure consistency, and reduce pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

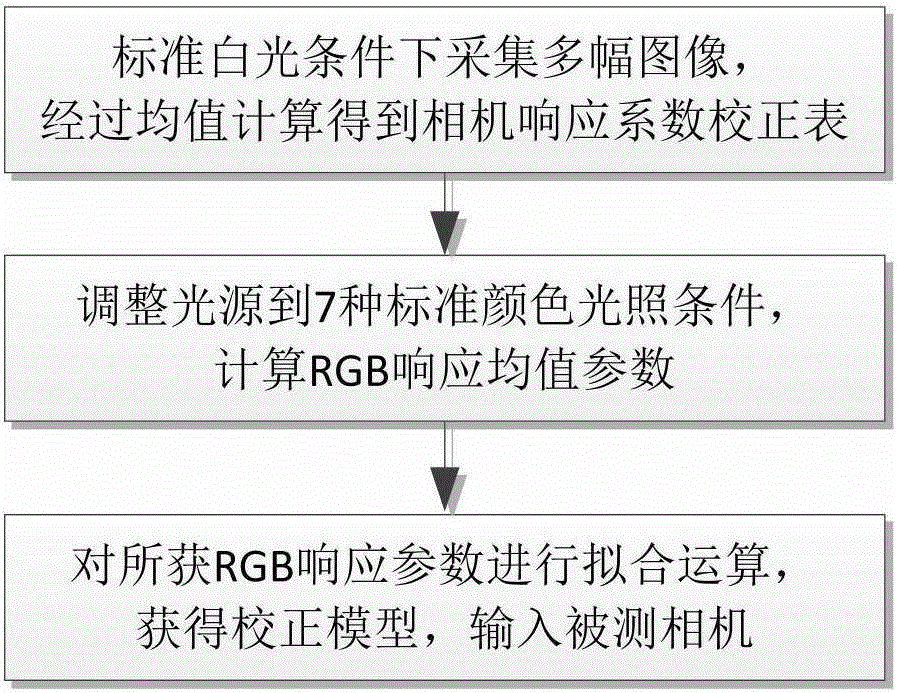

Method used

Image

Examples

Embodiment Construction

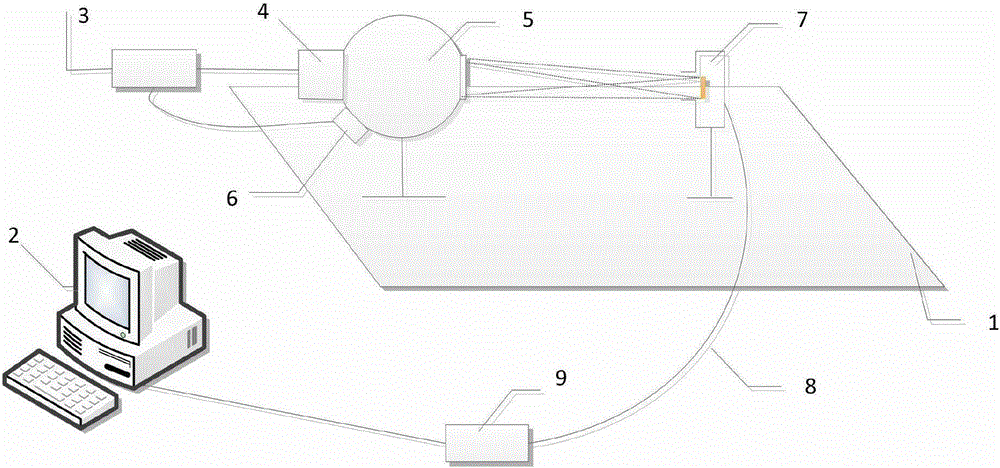

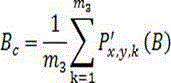

[0019] Such as figure 1 As shown, an industrial color camera color response test and correction device of the present invention, the whole device is placed in a dark room, including a computer 2, an LED drive controller 3, an RGB three-color LED array light source 4, an integrating sphere 5, and a colorimeter 6, the camera to be tested 7, the data transmission cable 8, the data acquisition card 9; the camera to be tested 7 and the integrating sphere 5 are all placed on the optical platform 1, the camera to be tested 7 is connected to the data acquisition card 9 through the data transmission cable 8, and the computer 2. Obtain image data through the data acquisition card 9. The light outlet of the integrating sphere 5 is vertically aligned with the camera 7 to be tested, so that the light is evenly irradiated on the sensor of the camera 7 to be tested; the distance from the light outlet of the integrating sphere 5 to the sensor of the camera 7 to be tested is not less than the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com