Two-part steel piston, joining process

A two-piece, piston technology, applied in the direction of piston, assembly from parts, engine components, etc., can solve problems such as consumption and achieve the effect of stable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

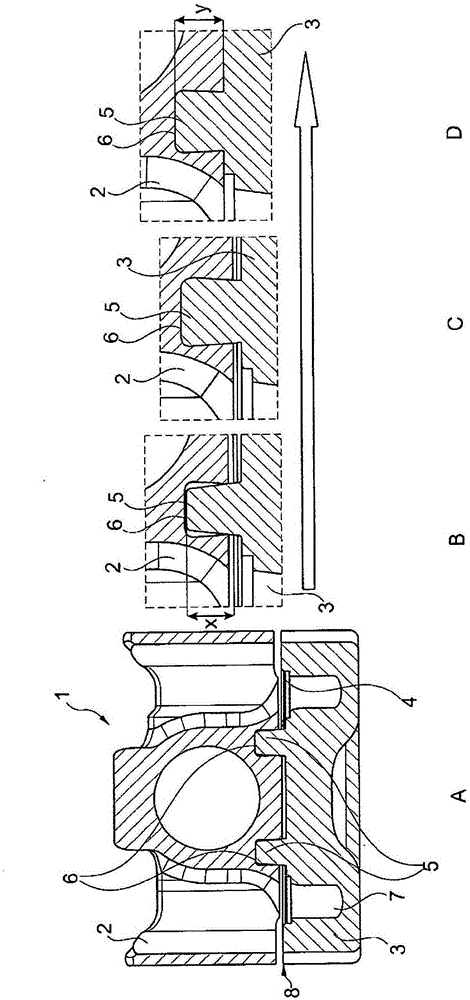

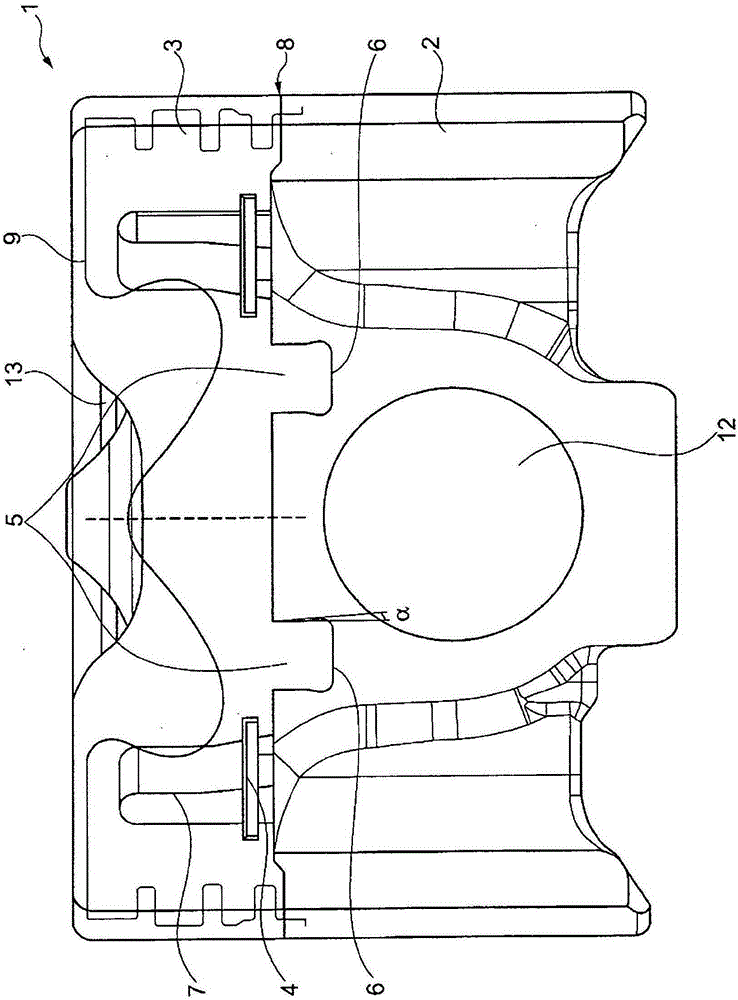

[0028] In the following description of the figures, terms such as top, bottom, left, right, front, rear etc. refer only to the selected exemplary illustrations and positions of the devices and other elements in the corresponding figures. These concepts are not to be understood as limiting, ie the references can be changed by different positions and / or mirror-symmetrical designs etc.

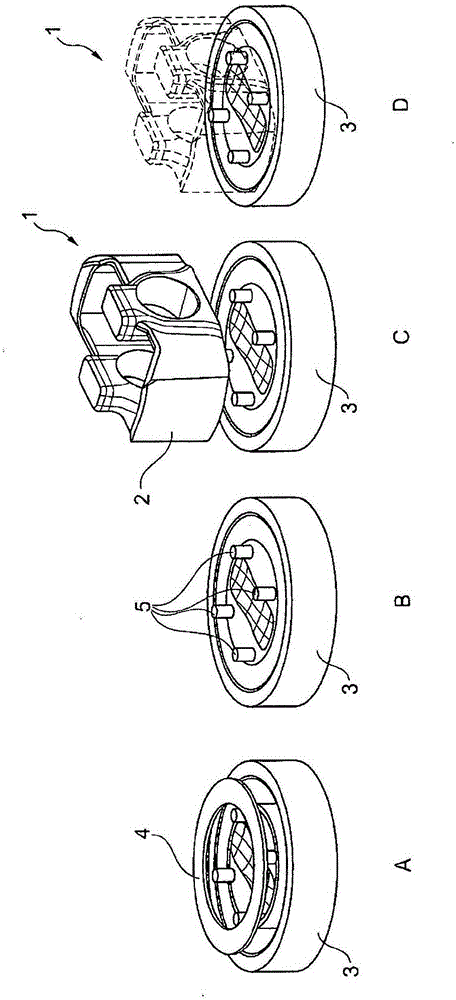

[0029] figure 1 A to 2D illustrate the joining process according to the invention using the example of a cooling channel piston. The method is not limited to cooling channel pistons, pistons without cooling channels can also be produced according to the method according to the invention.

[0030] all figure 1 A to ID show plan views of the underside (in the operating position) of the upper part 3 of the piston blank 1 .

[0031] exist figure 1 In A, the ring 4 for forming the cooling channel 7 is inserted into the upper part 3 at the top end. When the lower part 2 is then provided and the co...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap