A continuous casting slab longitudinal crack breakout detection and prediction device and its detection method

A detection method and slab technology, applied in the configuration of indicating equipment/measuring equipment, casting equipment, manufacturing tools, etc., can solve the problems of difficult monitoring of temperature changes, failure to predict longitudinal cracking of slabs well, and achieve Promote high value effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below based on specific embodiments and in conjunction with the accompanying drawings.

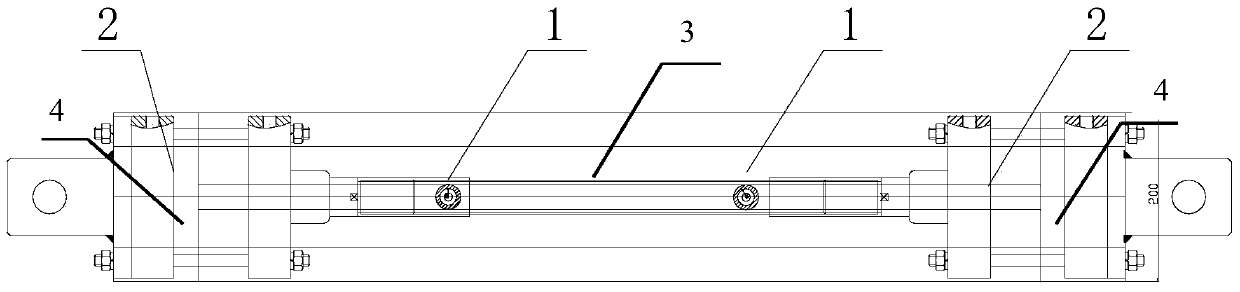

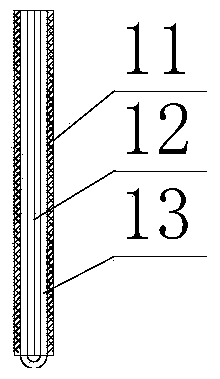

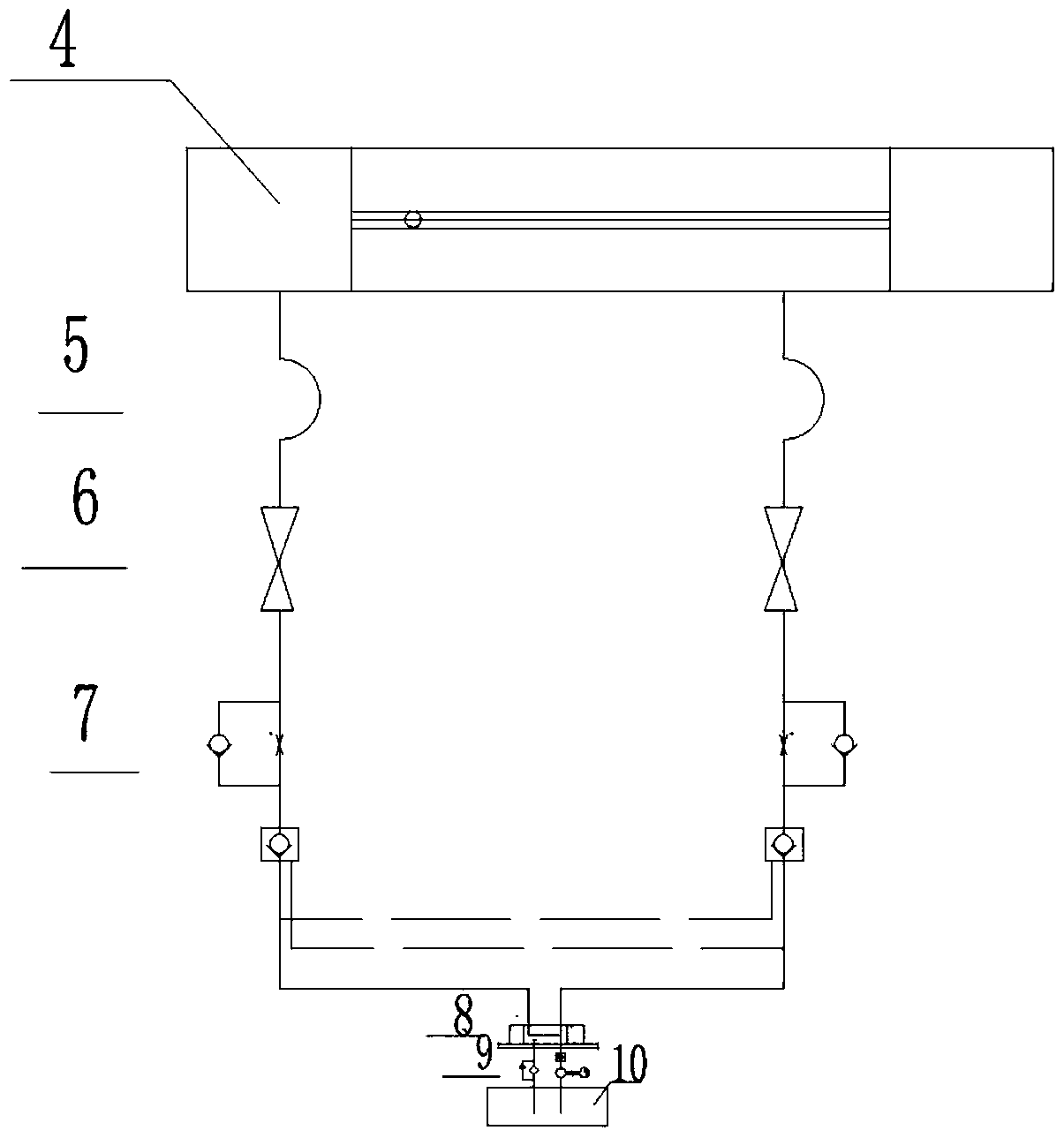

[0020] refer to Figure 1 ~ Figure 3 As shown, the continuous casting slab longitudinal crack breakout detection and prediction device according to the present invention is installed in the area of 1# sector to 2# sector under the crystallizer of the slab continuous casting machine, including high temperature resistant cermet detectors. Needle 1, metal guide rod 2, guide groove 3, hydraulic cylinder 4, hydraulic lock 5, one-way throttle valve 7, reversing valve 8, hydraulic pump 9, oil tank 10 and PLC control system, the high temperature resistant cermet probe The needle 1 is installed on the metal guide rod 2, and the metal guide rod 2 is connected with the hydraulic cylinder 4, the hydraulic cylinder 4, the hydraulic lock 5, the ball valve 6, the one-way throttle valve 7, the reversing valve 8, the hydraulic pump 9, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com