Pyramid-shaped lattice sandwich shell made of composites and preparation method of pyramid-shaped lattice core sandwich shell

A technology of composite materials and pyramids, which is applied in the field of composite material pyramid-shaped lattice sandwich shells and its preparation, can solve the problems of inaccessibility of lattice core spaces, excessive manual operations, and complicated preparation processes, and achieves a wide range of applications , Less manual operation, simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

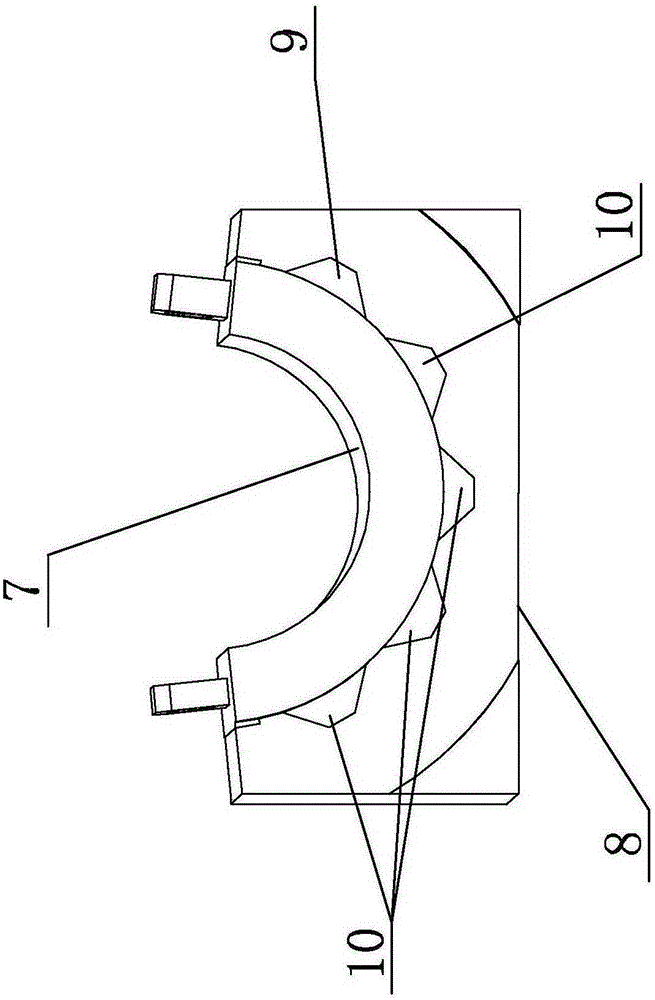

[0024] Specific implementation mode one: combine figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 Describe the present embodiment, which includes a pyramid-shaped lattice core 1, a composite material inner panel and a composite material outer panel;

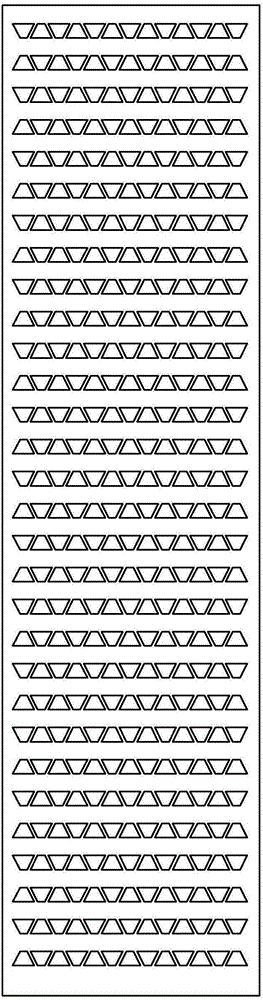

[0025] The pyramidal lattice core 1 comprises N inner core bars 4, N outer core bars 5, a plurality of pyramidal lattice structure unit cells 6, and the N inner core bars 4 and N outer core bars Core strips 5 are staggered to form a cylinder, N inner core strips 4 are arranged close to the central axis of the cylinder, N outer core strips 5 are arranged away from the cylindrical central axis, each inner core strip 4 A plurality of pyramid-shaped lattice structure unit cells 6 are arranged along the cylindrical axial direction between the adjacent outer core strips 5, and each pyramid-shaped lattice structure unit cell 6 is composed of four rods in order. The secondary connection forms a trapezoidal one piece, the i...

specific Embodiment approach 2

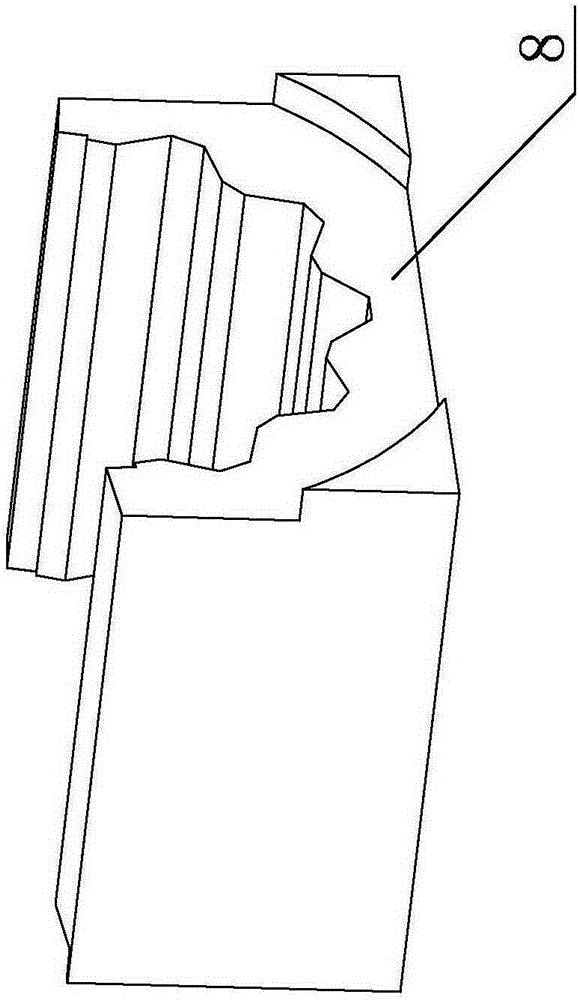

[0028] Specific implementation mode two: combination Figure 6 Describe this embodiment, in this embodiment, each pyramid-shaped lattice structure unit cell 6 comprises a long rod 6-1, a short rod 6-2 and two connecting rods 6-3, and the long rod 6-1 and the short rod 6-2 are parallel to each other, and the long rod 6-1 and the short rod 6-2 are connected by two connecting rods 6-3 to form a trapezoidal hole structure, between each inner core strip 4 and its adjacent outer core A plurality of short rods 6-2 in a plurality of pyramidal lattice structure unit cells 6 between the sub-bars 5 are staggered from top to bottom, and the long rods 6-1 in each pyramidal lattice structure unit cell 6 are connected with each other. The short rods 6-2 in two adjacent pyramidal lattice structure unit cells 6 are on the same straight line. Other unmentioned structures and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0029] Specific implementation mode three: combination figure 2 , image 3 , Figure 4 and Figure 5 Describe this embodiment, in this embodiment, the outer surface of each pyramid-shaped lattice structure unit cell 6 is bonded with the outer panel of the composite material, and the inner surface of each pyramid-shaped lattice structure unit cell 6 is bonded to the inner surface of the composite material. The panels are glued together.

[0030] In this embodiment, the inner surface of each pyramid-shaped lattice structure unit cell 6 is glued to the composite material inner panel by resin, and the outer surface of each pyramid-shaped lattice structure unit cell 6 is bonded to the composite material outer panel by resin. Other unmentioned structures and connections are the same as those in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com