Self-propelled wave force power generation platform and moving and berthing method thereof

A wave force and platform technology, applied in ocean energy power generation, engine components, machines/engines, etc., can solve the problems of difficult cleaning and maintenance of underwater mooring equipment, high cost of marine engineering, high recycling costs, etc., to achieve protection and cleanliness And the effect of safety, cheap, easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

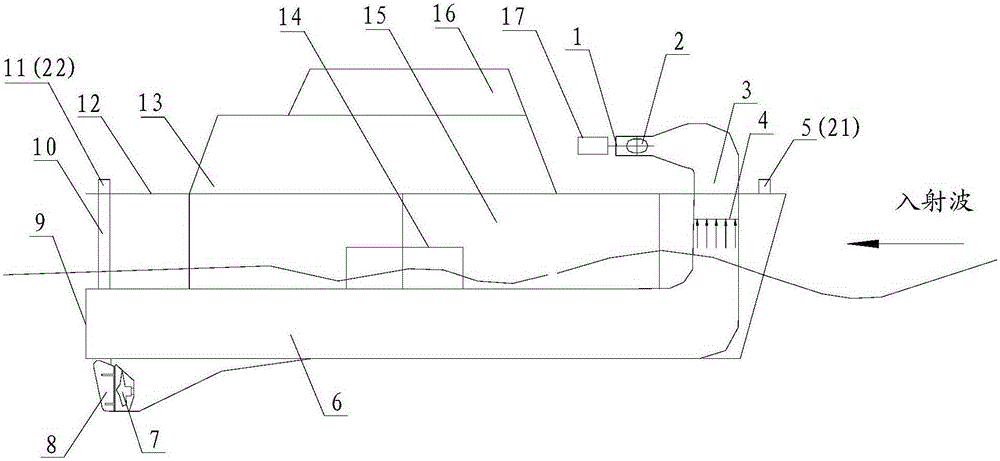

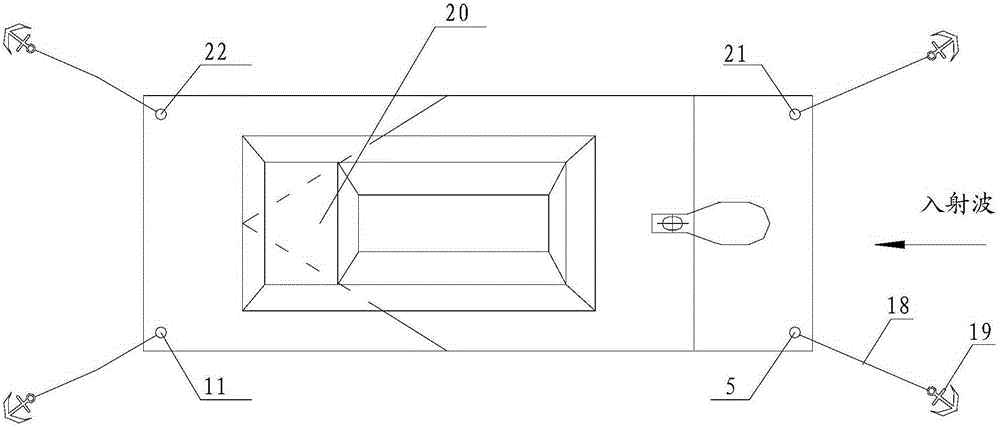

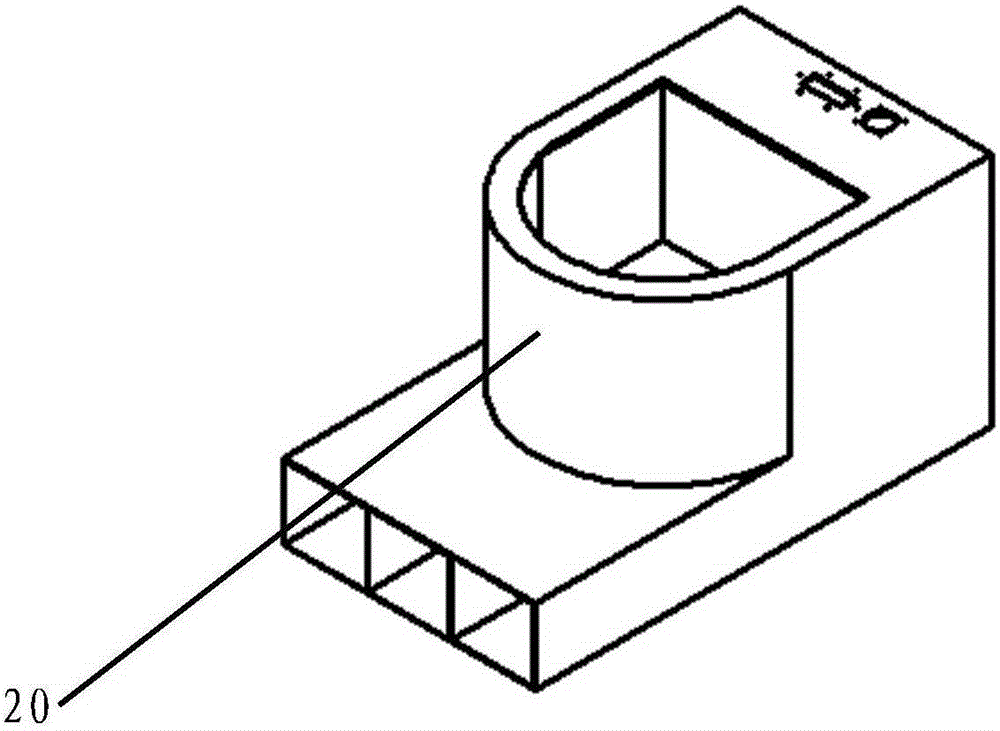

[0030] Such as Figure 1-2 As shown, a self-propelled wave power generation platform includes a back bend 6 and a buoyancy chamber 15 arranged on the back bend 6, the rear port 9 of the back bend 6 is located below the sea surface, and the back bend 6 The front end 1 is located above the sea surface and is connected with an air turbine 2, a wave generator 17 is connected to the air turbine 2, and a rectangular deck 12 is arranged on the buoyancy chamber 15, and the rectangular deck 12 extends to the rear end of the rear curved pipe 6 , a support rod 10 supporting a rectangular deck 12 is provided above the rear end of the rear bend 6, and electric windlasses 5, 11, 21, 22 are respectively symmetrically arranged on the four corners of the rectangle deck 12, and the rear bend 6 The rear end below is provided with electric thruster 7 and electric rudder 8.

[0031]The wave power generation platform includes a backbend 6 and a buoyancy chamber 15. The buoyancy chamber 15 provides...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com