Method for reducing wastewater generation during clean papermaking

A clean production and wastewater technology, applied in the field of papermaking, can solve the problems of wasting money and resources, and achieve the effects of saving water transmission power costs, reducing processing loads, and reducing floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

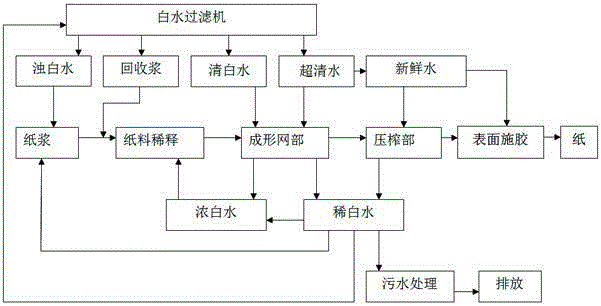

[0023] like figure 1 As shown, the existing clean paper production process, the general process is as follows:

[0024] The prepared pulp is prepared into paper after successively going through the processes of stock dilution, forming wire section, press section and surface sizing. A large amount of dilute white water and concentrated white water will be produced in the forming wire process, and a large amount of dilute white water will also be produced in the press part process. After the dilute white water produced in the two processes is directly mixed and concentrated, part of the input concentrated white water will enter together with the concentrated white water. The paper material dilution process is reused, part of it enters the white water filter for filtration treatment, and the remaining thin white water is first treated with sewage and discharged after reaching the standard. After the thin white water is processed by the white water filter, the turbid white water ...

Embodiment 2

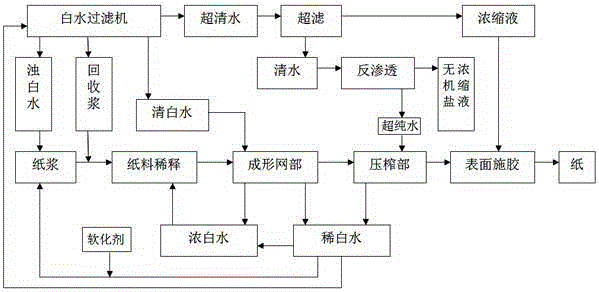

[0027] The method for reducing waste water in the papermaking clean production of the present application, the technological process is as follows figure 2 As shown, the specific process is as follows:

[0028] The prepared pulp is prepared into paper after successively going through the processes of stock dilution, forming wire section, press section and surface sizing. A large amount of dilute white water and concentrated white water will be produced in the forming wire process, and a large amount of dilute white water will also be produced in the press part process. After the dilute white water produced in the two processes is directly mixed and concentrated, part of the input concentrated white water will enter together with the concentrated white water. The paper material dilution process is reused, part of it enters the white water filter for filtration, and the remaining thin white water is fed into the pulp for use after adding a softener. After the dilute white wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com