Method for preventing burning explosion of ammonium nitrate in nitrate-sulfur-based compound fertilizer tower granulation production process

A technology of nitrosulfur-based compound fertilizer and high-tower granulation, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve the problems of poor stability of mixed materials, no safety design, hidden dangers of construction sites and construction workers, etc. Reduced catalysis, reduced risk of thermal runaway, reduced contact time effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

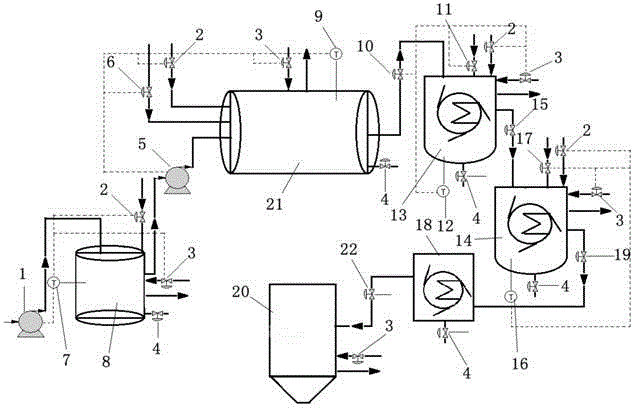

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but the present invention is not limited to these embodiments.

[0036] Such asfigure 1 As shown, a device for preventing the explosion of ammonium nitrate in the high-tower granulation production process of nitrosulfur-based compound fertilizer, including an over-temperature alarm interlock protection system, a heating steam supply part, a water supply part, a belt feeder and sequentially connected Middle tank 8, melter 21, No. 1 mixing tank 13, No. 2 mixing tank 14, homomixer 18, granulator 20, ammonium nitrate is sent into middle tank 8, melter 21, No. 1 mixing tank 13, No. 2 mixing tank 14, granulator 20.

[0037] The middle tank 8, the melter 21, the No. 1 mixing tank 13, and the No. 2 mixing tank 14 are respectively connected to the heating steam supply part through the heating steam delivery pipeline, and a heating steam valve 3 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap