A combined phc pipe pile that reduces negative frictional resistance

A PHC pipe pile, negative friction technology, applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problems of increasing the pile pressure, reducing the vertical bearing capacity of the pile foundation, etc. The effect of improving side friction resistance and eliminating negative friction resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

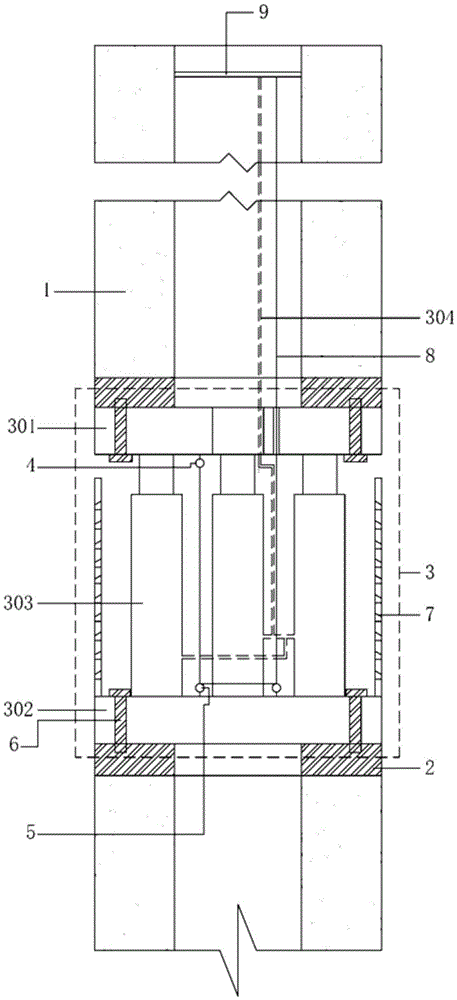

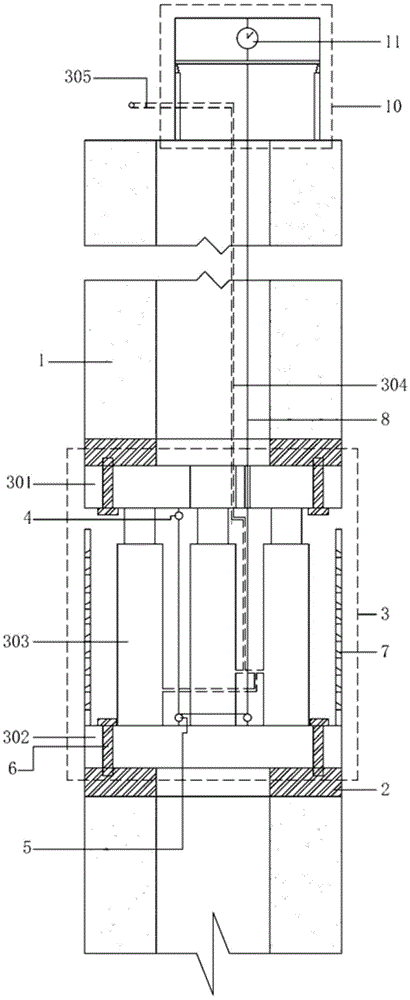

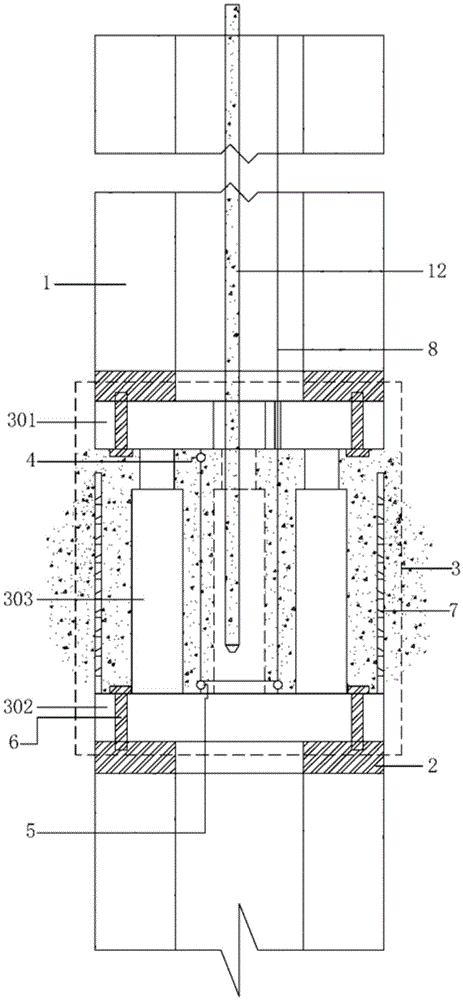

[0031] The invention relates to a PHC pipe pile with reduced negative frictional resistance, comprising a PHC pipe pile 1, a flange 2, a telescopic part 3, a hook 4, a small pulley 5, a steel strand 8, an isolation plate 7, a bolt 6, Pile inner bracket 9 , displacement transmission device 10 , displacement gauge 11 and grouting pipe 12 .

[0032] Such as figure 1 , 2 , 3, the telescopic part top plate 301 and the telescopic part bottom plate 302 are respectively connected to the flanges of the upper and lower sections of the PHC pipe pile by bolts 6, and the inner diameter of the telescopic part top plate 301 is smaller than the inner diameter of the PHC pipe pile 1; the hook 4 is welded on T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com