Underground structure seepage drainage system and construction method thereof

A technology for seepage and drainage and drainage ditch, applied in the direction of infrastructure engineering, construction, etc., can solve the problems of unfavorable cost saving, high precipitation cost, large impact on the surrounding environment, etc., achieving cost saving, small geological environment impact, and strong operability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing of description, but protection scope of the present invention is not limited thereto:

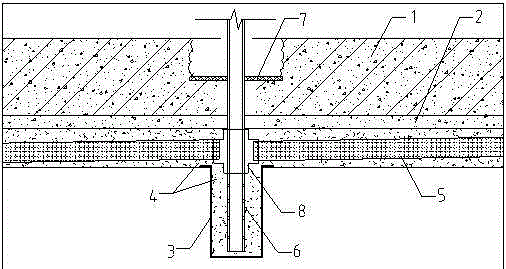

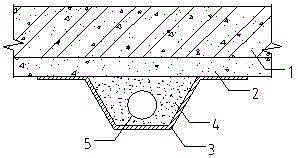

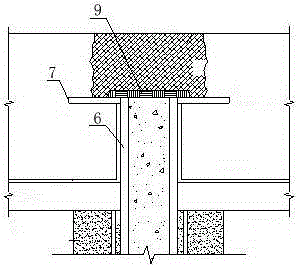

[0032] Such as Figure 1-2 As shown, a basement floor anti-floating seepage drainage system of the present invention includes a seepage drainage ditch, a water collection well, and a drainage point through the floor. The seepage drainage ditch communicates with the water collection well through a four-way joint, and the seepage drainage ditch is horizontal It is arranged under the bottom plate 1 of the engineering structure, and the water collection well is vertically concealed under the structure bottom plate. The seepage drainage ditch is composed of a geotextile filter 3, a crushed stone filter layer 4 and a water collection pipe 5 arranged horizontally. The water collection well is composed of The geotextile filter 3, the crushed stone filter layer 4 and the vertically arranged water co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com