Intelligent integrated prefabrication pump station

A pumping station, intelligent technology, applied in waterway systems, drainage structures, water supply devices, etc., can solve the problems of long construction period, high investment, large floor space, etc., to achieve the effect of simple structure, convenient use, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

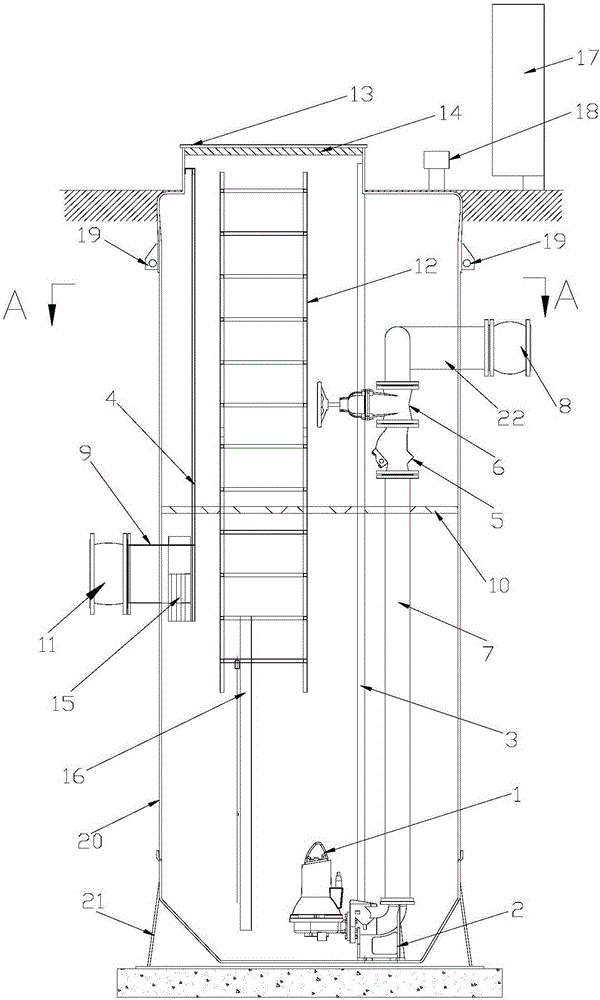

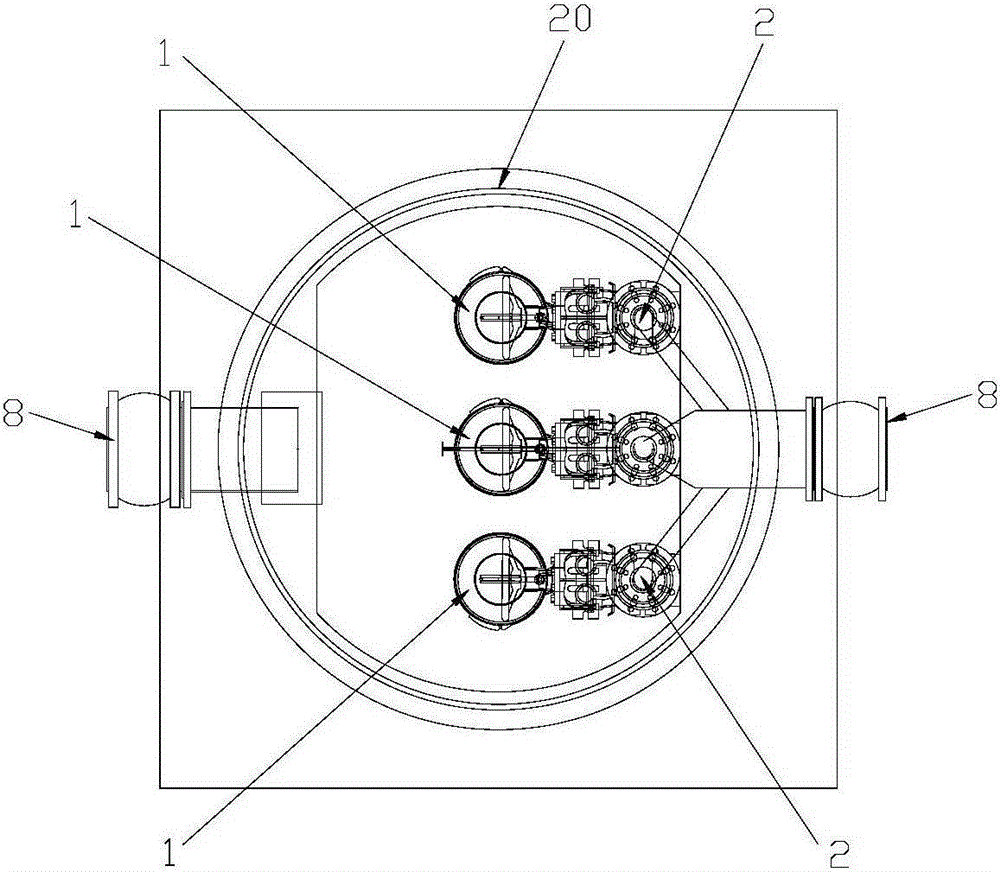

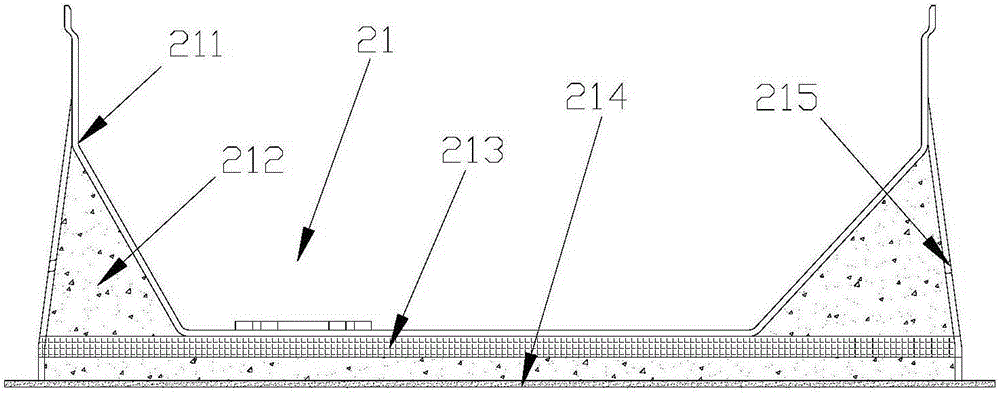

[0020] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

[0021] Such as Figures 1 to 4 As shown: an intelligent integrated prefabricated pump station according to the embodiment of the present invention, including a glass fiber reinforced plastic cylinder 20 and a pump station base 21, the glass fiber reinforced plastic cylinder is fixedly arranged on the pump station base, and the upper end of the glass fiber reinforced plastic cylinder is set There is an opening, and the opening is provided with a safety grill 14 and a well cover 13, and the well cover is arranged on the safety grill, and the inside of the glass fiber reinforced plastic cylinder 20 is provided with a water pump 1, a pressure pipe 7, a first guide rail 3, The second guide rail 4, the crushing grid 15, the ladder 12, the pressure sensor and the protection tube 16, the ladder is arranged in the glass fiber reinforced plastic cylinder b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com