Two-dimensional force feedback type electro-hydraulic servo valve based on two freedom degrees of valve element

An electro-hydraulic servo valve and degree of freedom technology, applied in servo motor components, fluid pressure actuating devices, mechanical equipment, etc., can solve the problems of low processing efficiency, high processing cost, difficult precision, etc., and achieve low processing cost and easy processing. The effect of processing and increasing the natural frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

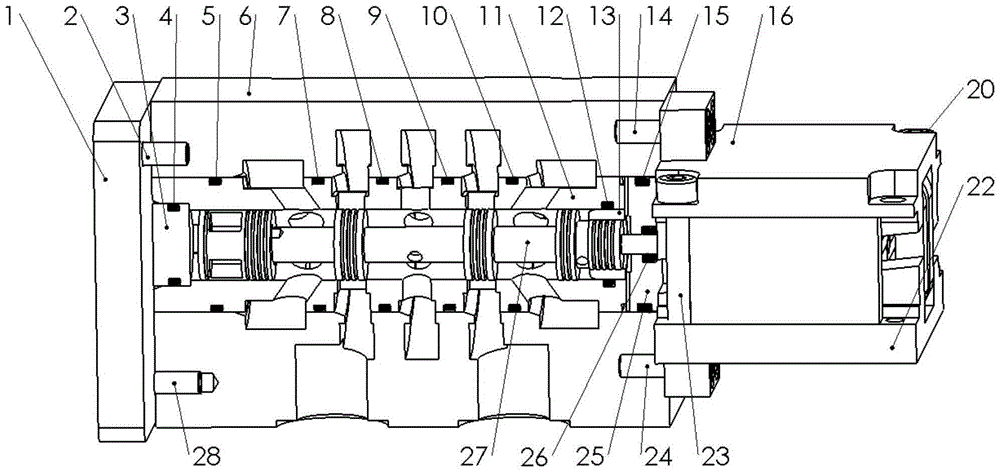

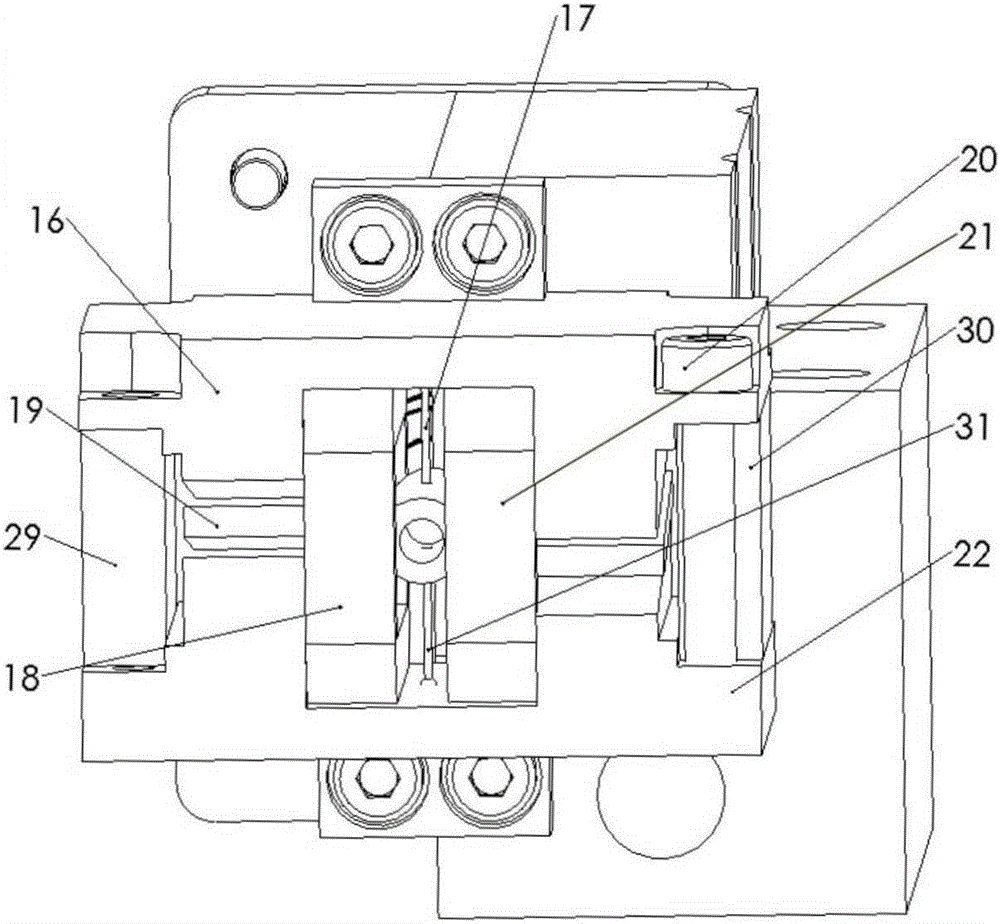

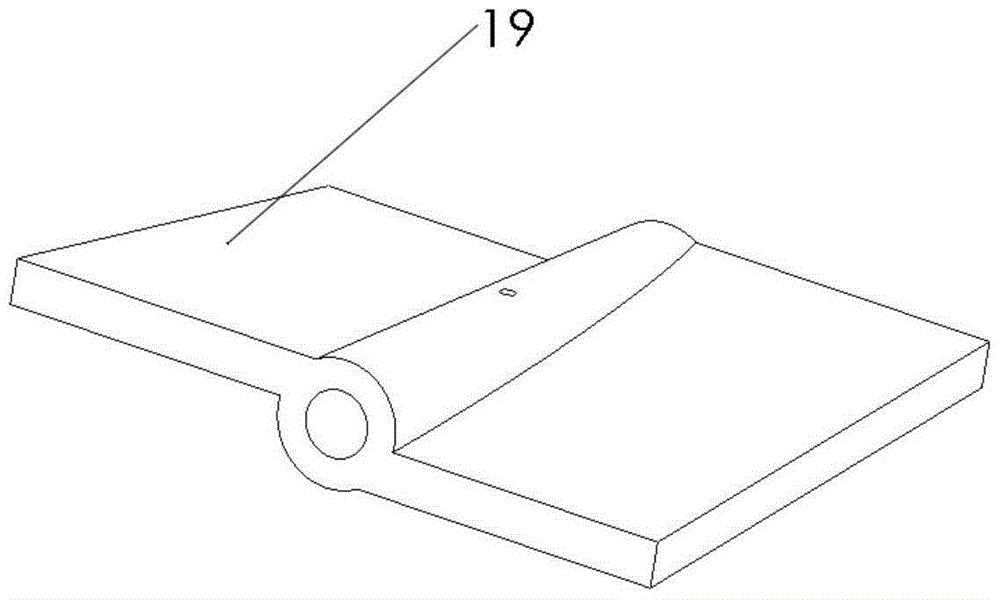

[0027] refer to Figure 1 ~ Figure 10, a two-dimensional force feedback electro-hydraulic servo valve, including an oblique wing torque motor and a hydraulic amplifying part. The oblique wing type torque motor consists of upper yoke 16, lower yoke 22, armature 19, first permanent magnet 29, second permanent magnet 30, first spring bar 17, second spring bar 31, first coil 18, second Coil 21 and fixing screw etc. are made up. The upper yoke 16, the lower yoke 22 and the armature 19 are all magnet conductors; the first permanent magnet 29 and the second permanent magnet 30 are symmetrically placed on the outside of the upper yoke and the lower yoke respectively to provide polarized magnetic potential; A coil 18 and a second coil 21 are respectively symmetrically wound on the inside of the upper yoke and the lower yoke to provide control magnetic potential; the first spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com