Circular saw blade wear amount online measurement method based on machine vision

A measurement method and machine vision technology, applied in the field of image processing, can solve the problems of inability to realize online measurement of the wear amount of circular saw blades, difficult to find, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

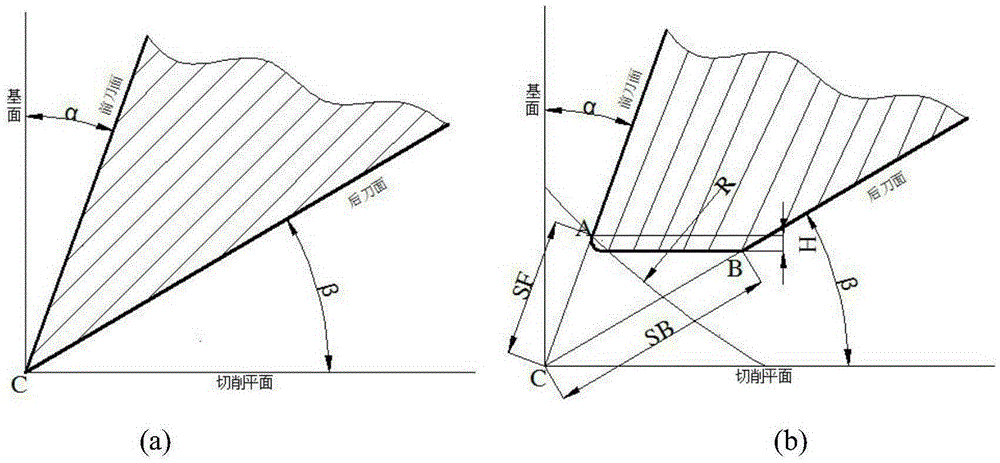

[0077] When cutting, the circular saw blade and the workpiece move relatively, under the action of the cutting force, wear occurs, and the shape of the cutting edge changes (such as figure 1 shown). A is the frontmost point of the rake face, that is, the entry point of the cutting edge; B is the contact point between the flank and the workpiece, and C is the ideal point of the tool tip. The three parameters of mouth wear SB and negative clearance H are used to measure the wear of circular saw blades, where SF reflects the wear of the rake edge of the tool, SB reflects the wear of the flank edge of the tool, and H reflects the cutting edge wear. The deformation of the workpiece caused by the extrusion of the cutting edge on the workpiece.

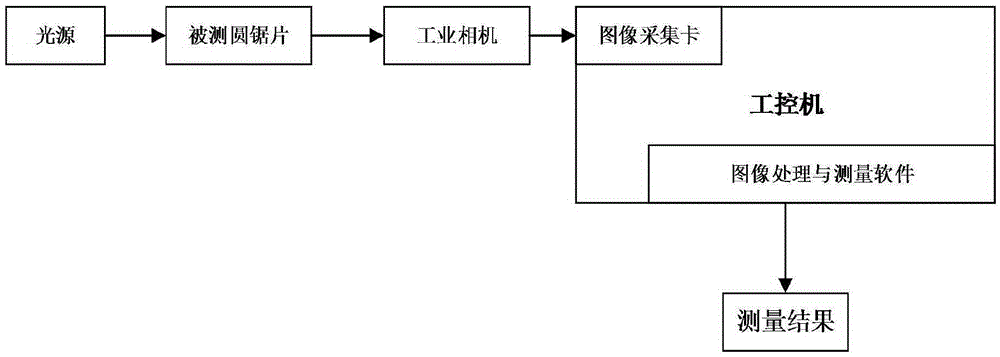

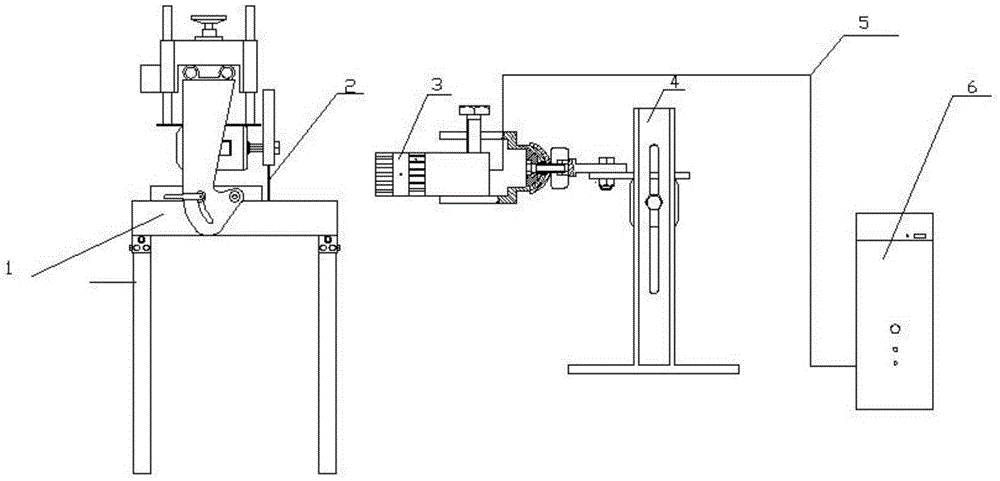

[0078] Before the online measurement of the wear amount of the circular saw blade, the industrial camera is calibrated. The method is to install a calibration object with a known size at the position where the circular saw blade is installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com