System and method for detecting product shape integrity based on asynchronous time domain vision sensor

A visual sensor and integrity technology, applied in the direction of instruments, measuring devices, optical devices, etc., can solve the problems of huge processing and storage pressure, large delay, large system processing and storage pressure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

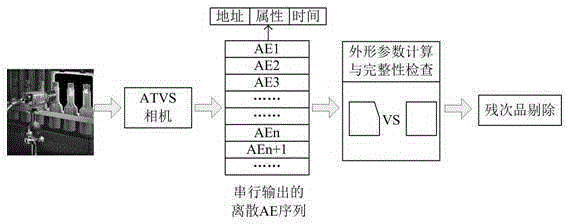

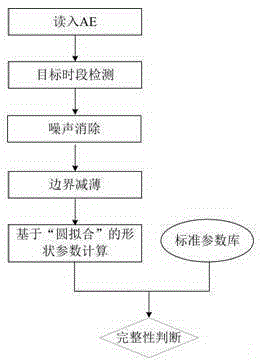

[0093] 1. The hardware framework of the industrial assembly line product shape integrity inspection system using TVS

[0094] figure 1 In order to use TVS to carry out the overall block diagram of the industrial assembly line product shape integrity inspection system, it includes the following parts:

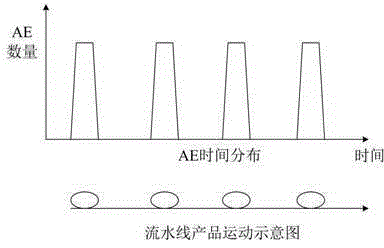

[0095] 1. TVS-based industrial cameras take pictures of products moving serially on the industrial assembly line one by one. Because the shooting background is fixed and the ambient lighting is constant, the output data is only moved by the product, including:

[0096] (1) TVS, including pixel array, output arbitration circuit and other modules, pixels independently sense the change of scene light intensity, and produce AE after arbitration for serial output;

[0097] (2) Interface controller. One of the functions of the interface controller is to receive the AE of the TVS and time stamp it to output; the second function is to receive an external control signal and change the working p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com