Electronic paper tape papermaking quality online detection system

A detection system and paper tape technology, which is applied in the field of papermaking, can solve the problems of paper yield decline, waste, cracks, and holes that cannot be detected, so as to improve the yield and avoid ineffective production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

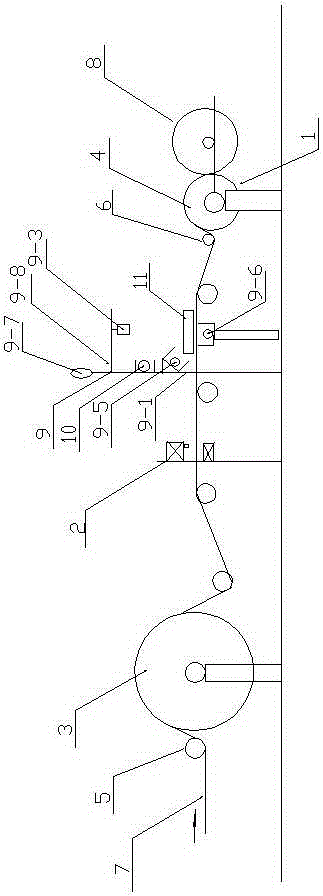

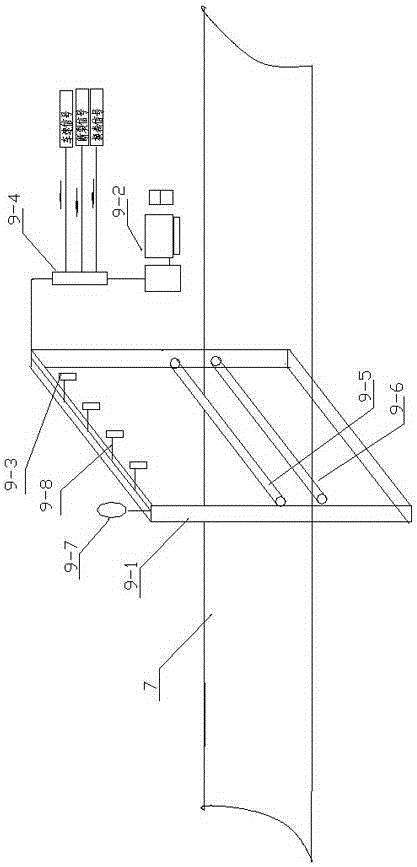

[0017] Example: such as figure 1 --2 shown;

[0018] An electronic paper tape papermaking quality online detection system, comprising a horizontal winder 1, the horizontal winder 1 is sequentially provided with a first guide roller 5, a cold water cylinder 3, a scanning instrument 2, second guide roller 6, reeling cylinder 4 and paper cylinder 8, said scanner 2 is installed above the paper web 7, and reciprocates longitudinally along the two ends of the paper web 7 banner, and said paper machine reeling system It also includes an online surface defect detection system 9 and an insect repellent device arranged between the scanner 2 and the second guide roller 6. The surface defect online detection system 9 is connected to the vehicle speed signal of the horizontal reel 1, the paper break signal, Roll change signal; the insect repellent device includes a mosquito repellent lamp 10 and a blower 11, and the mosquito repellent lamp 10 and the blower 11 are set near the light sourc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com