Single crystal growth furnace and single crystal growth method

A growth furnace and crystal growth technology, applied in the direction of single crystal growth, crystal growth, chemical instruments and methods, etc., can solve the problems of uncontrollable single crystal yield and difficult monitoring of single crystal growth process, so as to avoid invalid production and save Production cost, effect of improving yield and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

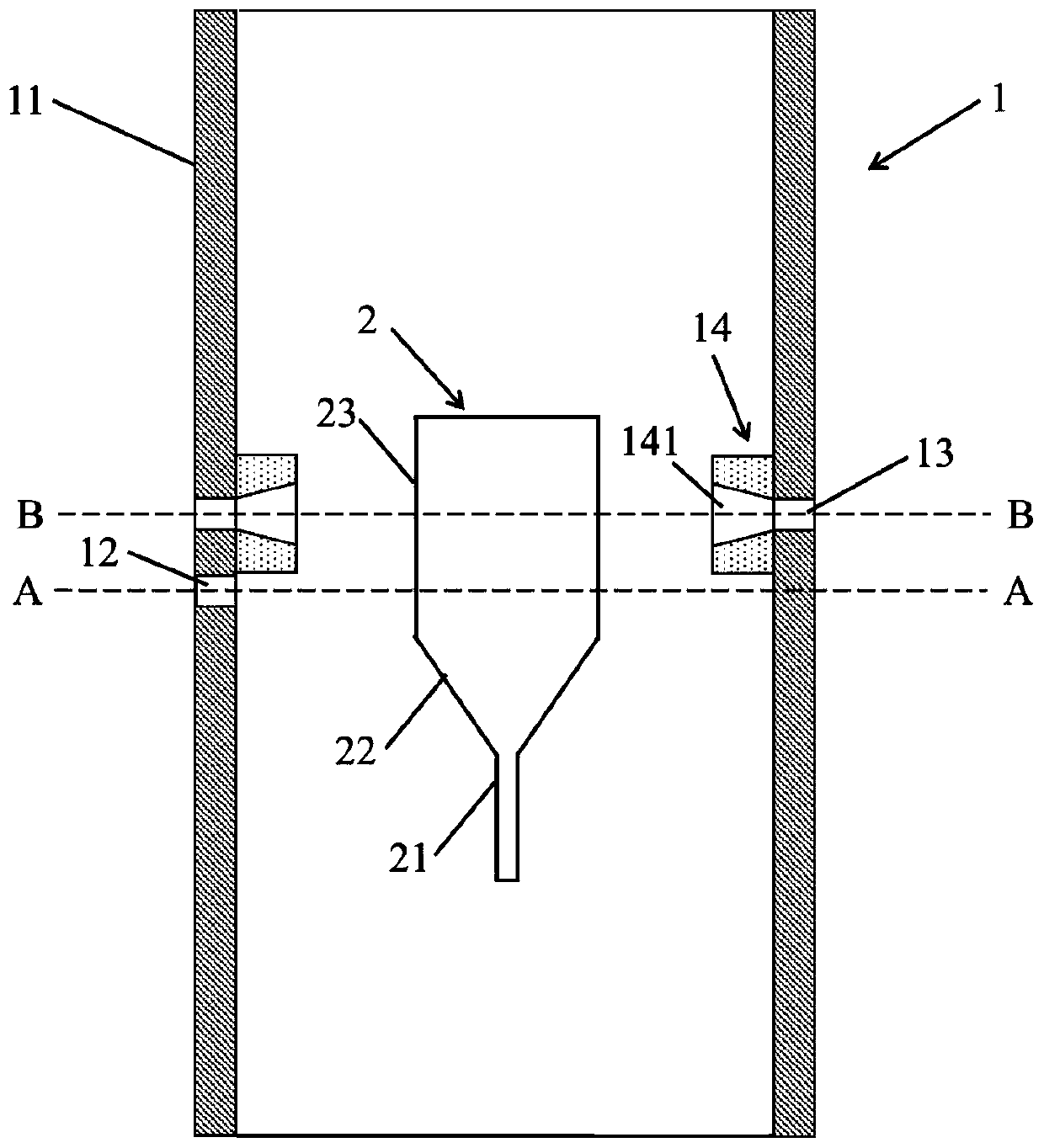

[0077] Embodiment 1 single crystal growth furnace

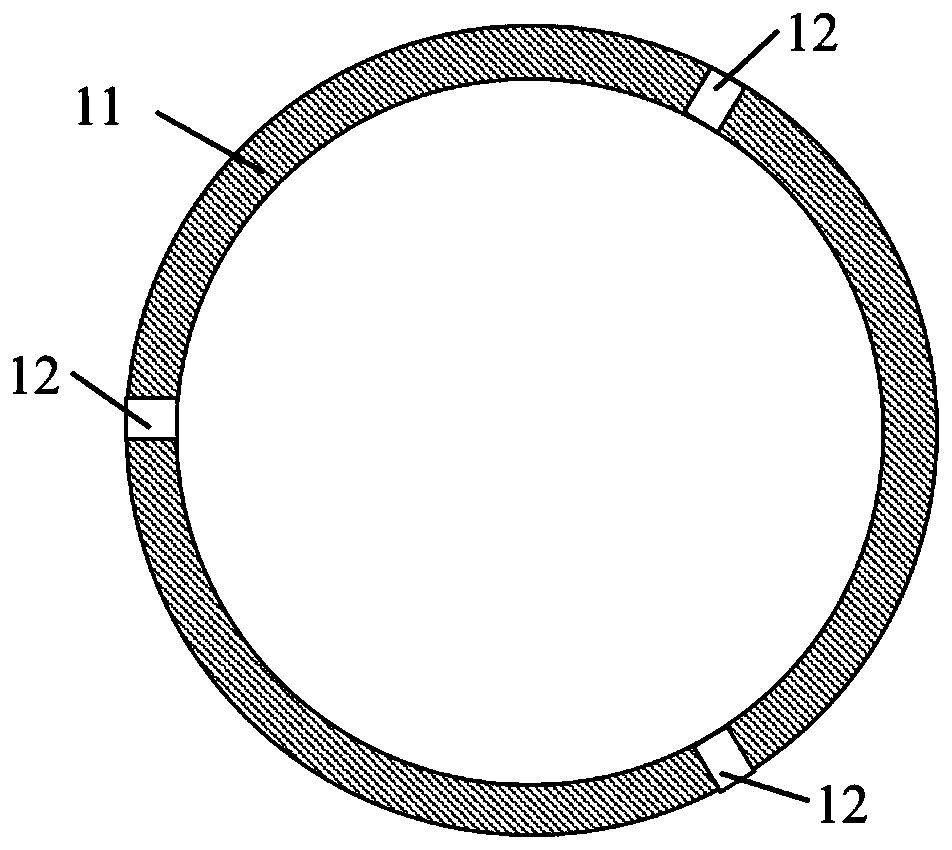

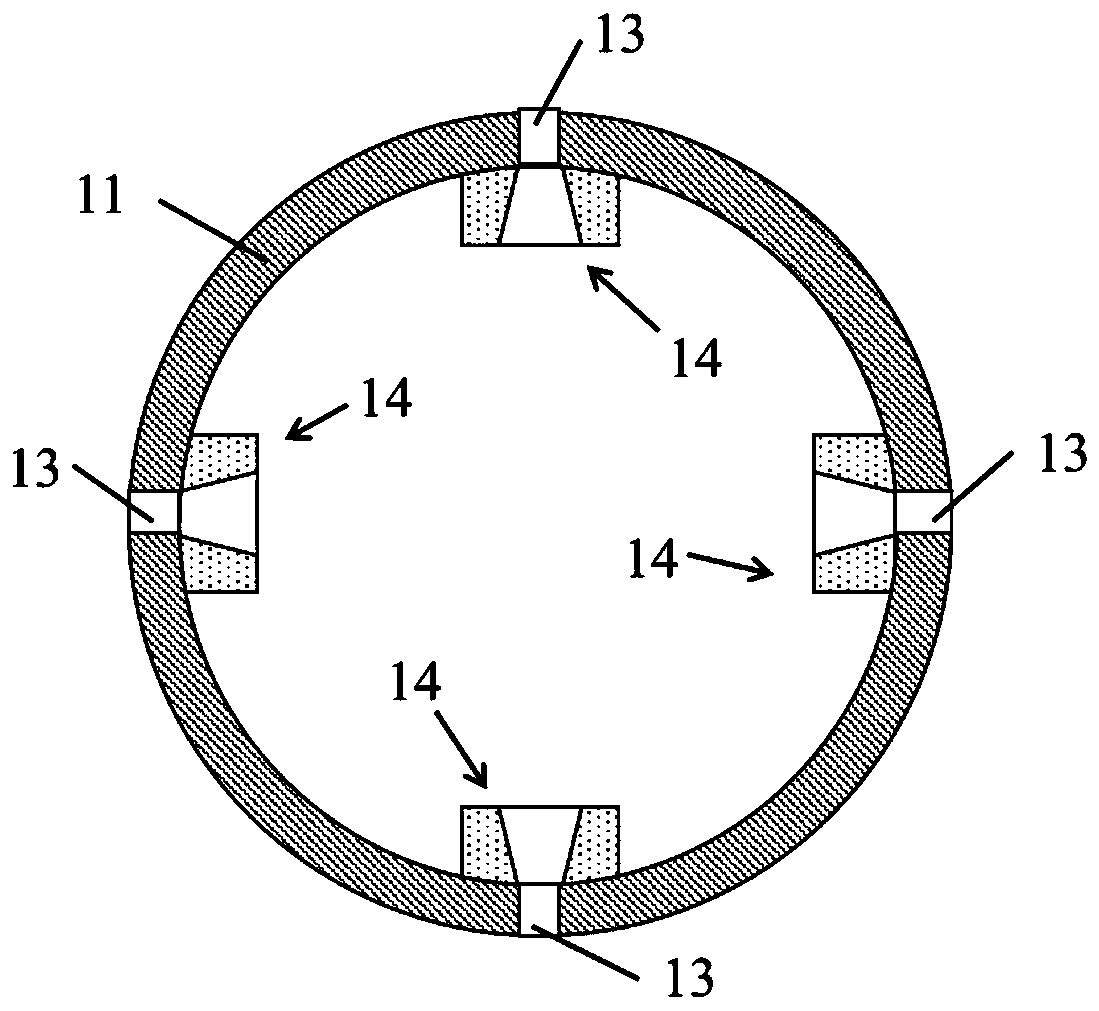

[0078] Such as Figure 1-3 As shown, the single crystal growth furnace 1 includes a furnace body 11, an observation device access hole 12, a laser heating device access hole 13, a protection member 14, and a heat preservation door. Other conventional components in a single crystal growth furnace, such as components forming a temperature field, are not shown.

[0079] The observation device access hole 12 is arranged on the furnace body 11 (ie, the furnace wall). Such as figure 2 As shown, in this embodiment, three observation device insertion holes 12 are provided, which are evenly distributed on a cross section of the furnace body 11 . The observation device access hole 12 is cylindrical, allowing the observation device to extend into it to observe the crystal growth inside the single crystal growth furnace 1 . Those skilled in the art know that the observation device insertion hole 12 can also have other shapes, which ...

Embodiment 2

[0084] Embodiment 2 single crystal growth system

[0085] The single crystal system of this embodiment includes the single crystal growth furnace 1 described in Embodiment 1, and also includes a crucible 2, an observation device (not shown), and a laser heating device (not shown).

[0086] The crucible 2 is arranged inside the single crystal growth furnace 1 , and optionally, the central axis of the crucible 2 coincides with the central axis of the single crystal growth furnace 1 . In this embodiment, the crucible 2 is a quartz crucible, and the crucible 2 can be divided into three regions: a cylindrical first region 21 with the smallest diameter, a cylindrical third region 23 with the largest diameter, and a cylindrical third region located between the first region 21 and the cylindrical third region. A conical second region 22 between the three regions 23 . In one embodiment, the observation device access hole 12 and the laser heating device access hole 13 of the single cry...

Embodiment 3

[0091] Embodiment 3 single crystal growth method

[0092] Single crystal growth was performed using the single crystal growth furnace as in Example 1, or the single crystal growth system as in Example 2. In this embodiment, the crucible is a quartz crucible, and a positioning scale is fixed on the outside of the crucible, the laser source of the laser heater is a fiber laser, and the production of CdZnTe single crystal is carried out by a vertical gradient fixation method.

[0093] Pre-production preparation: Before production, insert the camera of the high-temperature-resistant camera system into the observation device insertion hole 12 of the single crystal growth furnace 1, and the front end of the camera does not protrude out of the hole to reduce damage to the camera due to high temperature. Close the thermal insulation door outside the laser heating device insertion hole 13. The raw material is placed in a quartz crucible, and the temperature field of the single crystal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com