AGV quantity and work task matching method in AGV production scheduling system

A technology for production scheduling and work tasks, applied in the direction of control/adjustment system, general control system, comprehensive factory control, etc., can solve problems such as difficult production planning, expensive AGV, and increased production costs for enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

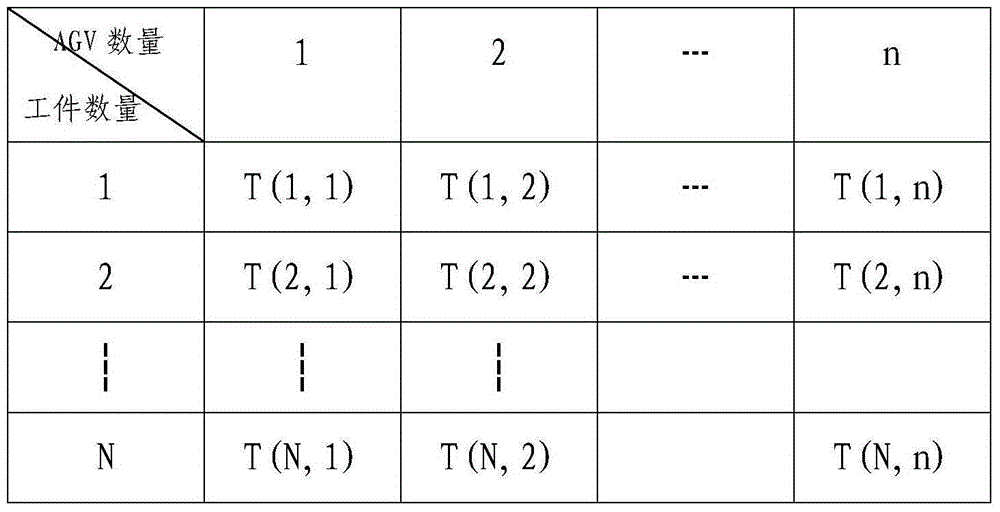

[0048] Principle of the present invention is specifically described as follows:

[0049] (1) The first part of the technical solution: the fixing device of the system mainly includes a loading platform, an unloading platform, multiple workbenches, multiple AGV waiting areas, and electromagnetic tracks connecting these fixing devices. In addition, the system also includes multiple movable AGVs. The data that needs to be obtained to measure the system includes the following categories:

[0050] First, the length of the electromagnetic track between two fixed devices such as loading platforms, unloading platforms, workbenches, and AGV waiting areas.

[0051] Second, the time required for AGV to load and unload work on the loading platform, unloading platform, and workbench and the processing time of each workbench.

[0052] Third, the running speed of the AGV and the reaction time to avoid obstacles when encountering obstacles.

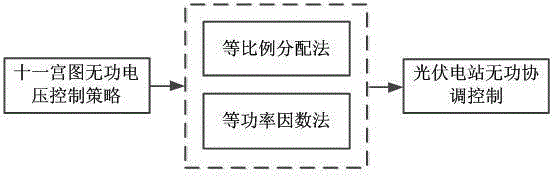

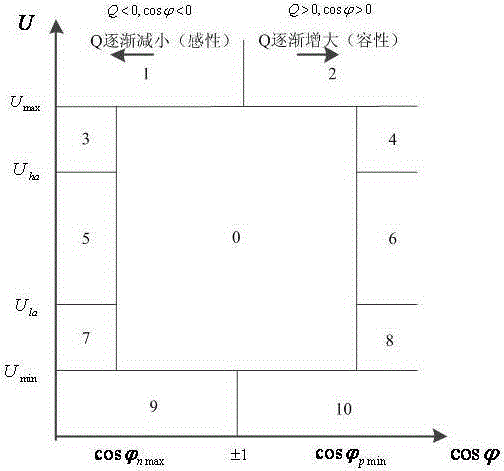

[0053] (2) The second part of the technical pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com