Solar photovoltaic component and preparation method thereof

A technology of solar photovoltaic and solar cells, applied in the field of solar energy, can solve the problems of low optical utilization rate and conversion efficiency, achieve high optical efficiency and conversion efficiency, improve utilization rate, and improve conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

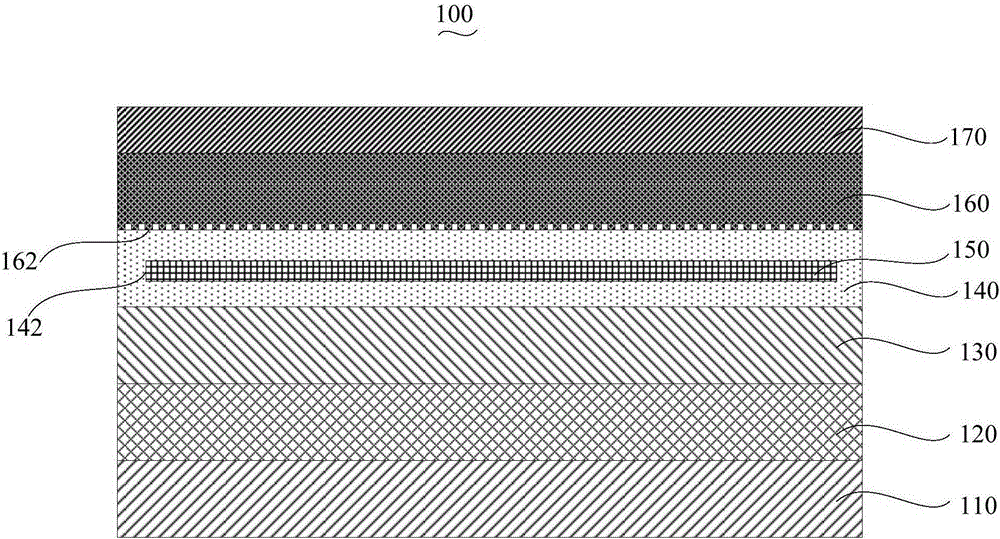

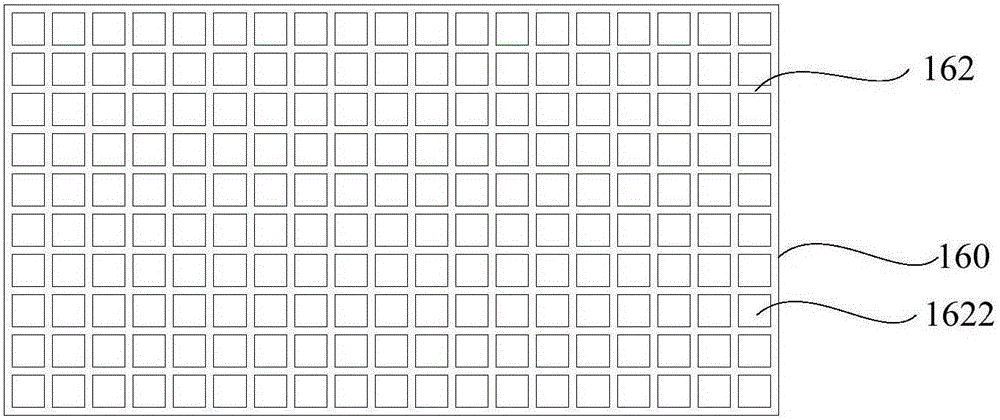

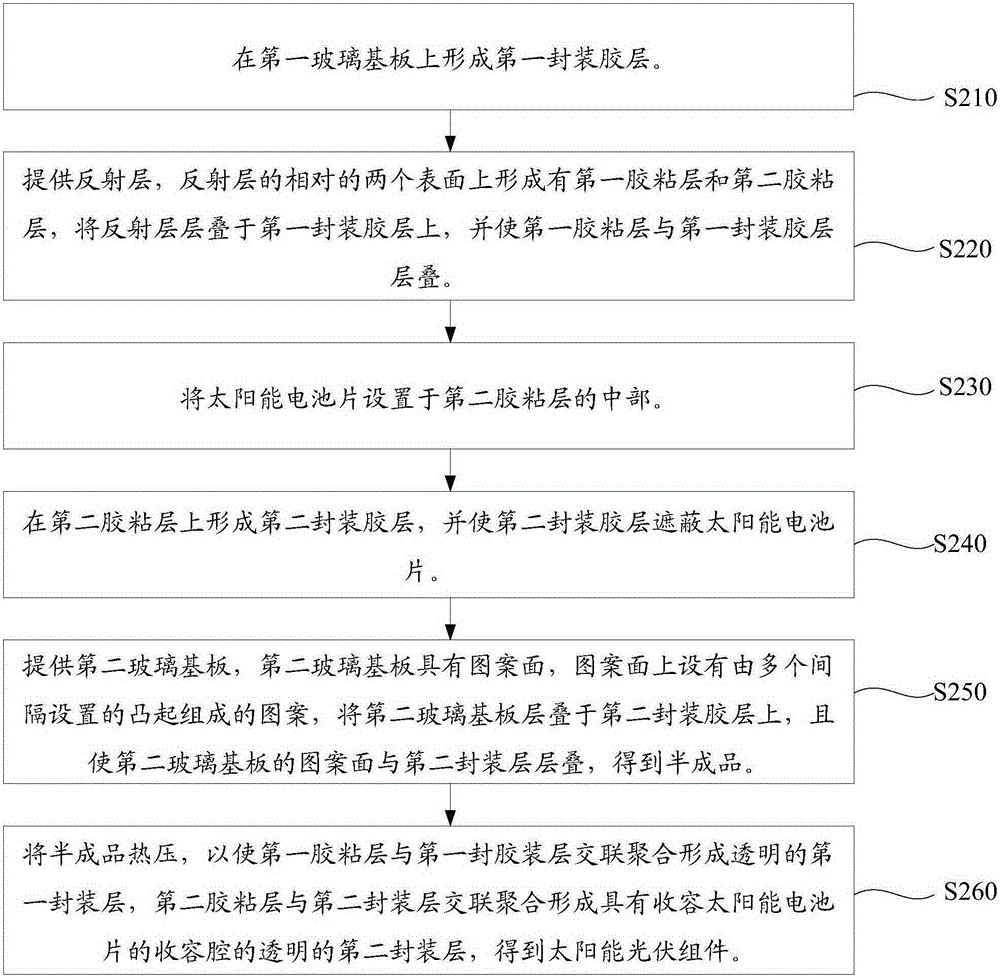

[0048] Such as image 3 As shown, a method for preparing a solar photovoltaic module according to an embodiment is a method for preparing the above solar photovoltaic module. The preparation method of the solar photovoltaic module comprises the following steps:

[0049] Step S210: forming a first packaging adhesive layer on the first glass substrate.

[0050] Wherein, the first glass substrate is a tempered glass plate or a semi-tempered glass plate. The thickness of the first glass substrate is 2 mm to 4 mm.

[0051] Wherein, the material of the first packaging adhesive layer is uncrosslinked ethylene-vinyl acetate copolymer (EVA). The thickness of the first encapsulation adhesive layer is 0.45mm-0.6mm.

[0052] Step S220: providing a reflective layer, a first adhesive layer and a second adhesive layer are formed on two opposite surfaces of the reflective layer, the reflective layer is stacked on the first packaging adhesive layer, and the first adhesive layer and The fi...

Embodiment 1

[0078] The preparation process of the solar photovoltaic module of the present embodiment is as follows:

[0079] (1) Forming a first packaging adhesive layer on the first glass substrate. Wherein, the first glass substrate is a toughened glass plate; the thickness of the first glass substrate is 3 millimeters; the material of the first packaging adhesive layer is uncrosslinked ethylene-vinyl acetate copolymer; the thickness of the first packaging adhesive layer is 0.5 mm.

[0080] (2) providing a reflective layer with a thickness of 150 microns and a reflectivity of 60%; coating uncrosslinked ethylene-vinyl acetate copolymers on opposite surfaces of the reflective layer respectively to form a thickness of 60 microns. An adhesive layer and a second adhesive layer with a thickness of 60 microns, the reflective layer is laminated on the first encapsulation adhesive layer, and the first adhesive layer and the first encapsulation adhesive layer are laminated, wherein the material...

Embodiment 2

[0089] The preparation process of the solar photovoltaic module of the present embodiment is as follows:

[0090] (1) Forming a first packaging adhesive layer on the first glass substrate. Wherein, the first glass substrate is a semi-tempered glass plate; the thickness of the first glass substrate is 2 millimeters; the material of the first packaging adhesive layer is uncrosslinked ethylene-vinyl acetate copolymer; the thickness of the first packaging adhesive layer is 0.45 mm.

[0091] (2) providing a reflective layer with a thickness of 50 microns and a reflectivity of 70%; coating uncrosslinked ethylene-vinyl acetate copolymers on opposite surfaces of the reflective layer respectively to form a thickness of 25 microns. An adhesive layer and a second adhesive layer with a thickness of 25 microns, the reflective layer is laminated on the first encapsulation adhesive layer, and the first adhesive layer and the first encapsulation adhesive layer are laminated, wherein the mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com