Simple cable stripping knife

A stripping knife and cable technology, which is applied in the direction of dismantling/armoring cable equipment, circuits, electrical components, etc., can solve the problems of poor force bearing, poor applicability, and poor tool durability, and achieve the elimination of safety hazards, high work efficiency, The effect of fast peeling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

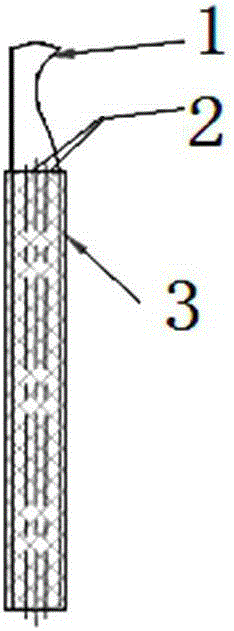

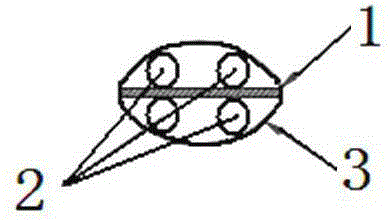

[0013] Embodiment: a kind of simple and easy cable stripping knife (see figure 1 ), which includes heat-shrinkable sleeve 3, the upper end of heat-shrinkable sleeve 3 is connected to wedge-shaped cutter head 1, the edge of wedge-shaped cutter head 1 is wedge-shaped, the blade is inside the wedge-shaped edge, and heat-shrinkable sleeve 3 is filled with waste wires 2, the heat-shrinkable sleeve 3 is fixed together with the wedge-shaped cutter head 1 through the waste wire filler 2 filled therein.

[0014] When making, you can choose a thicker waste saw blade to cut a suitable length, mark it with a marker pen and grind it with a grinding wheel. After grinding, sharpen the wedge-shaped cutter head, and then insert the handle into the heat-shrinkable sleeve Fill it with waste wires, adjust the position and perform heat shrink molding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com