A boat type laver harvester

A harvester and seaweed technology, which is applied to harvesters, agricultural machinery and implements, applications, etc., can solve the problems of large required power, low action efficiency, unsafe hidden dangers, etc., and achieve smooth travel and sliding, simple structure and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

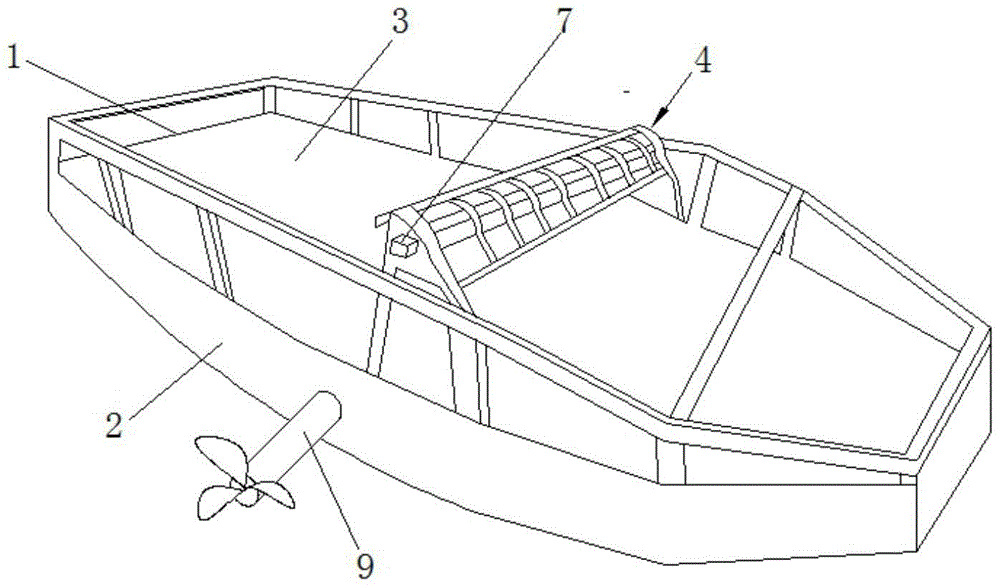

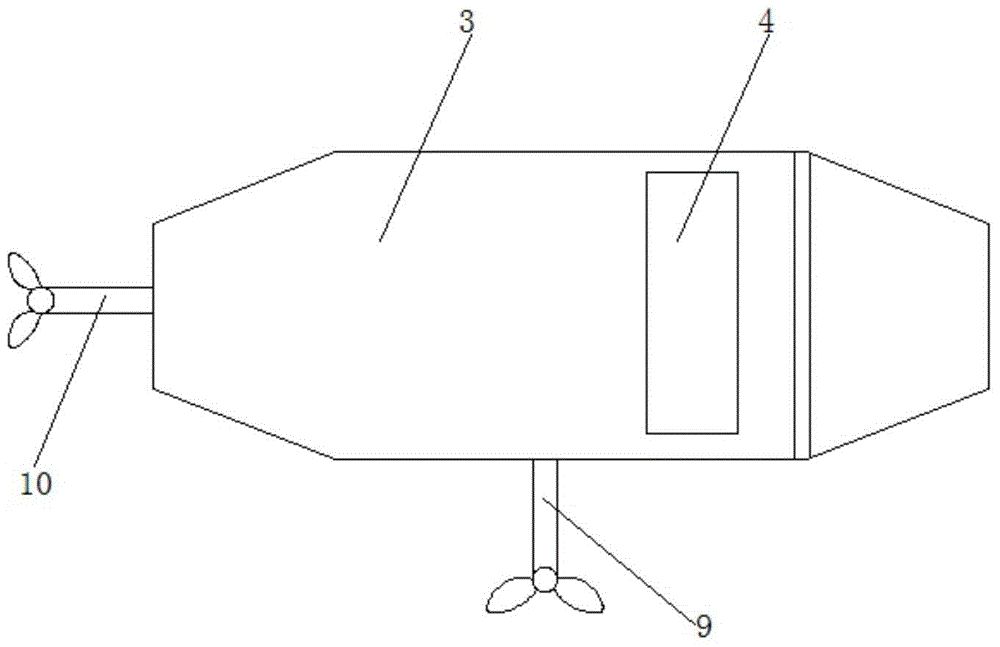

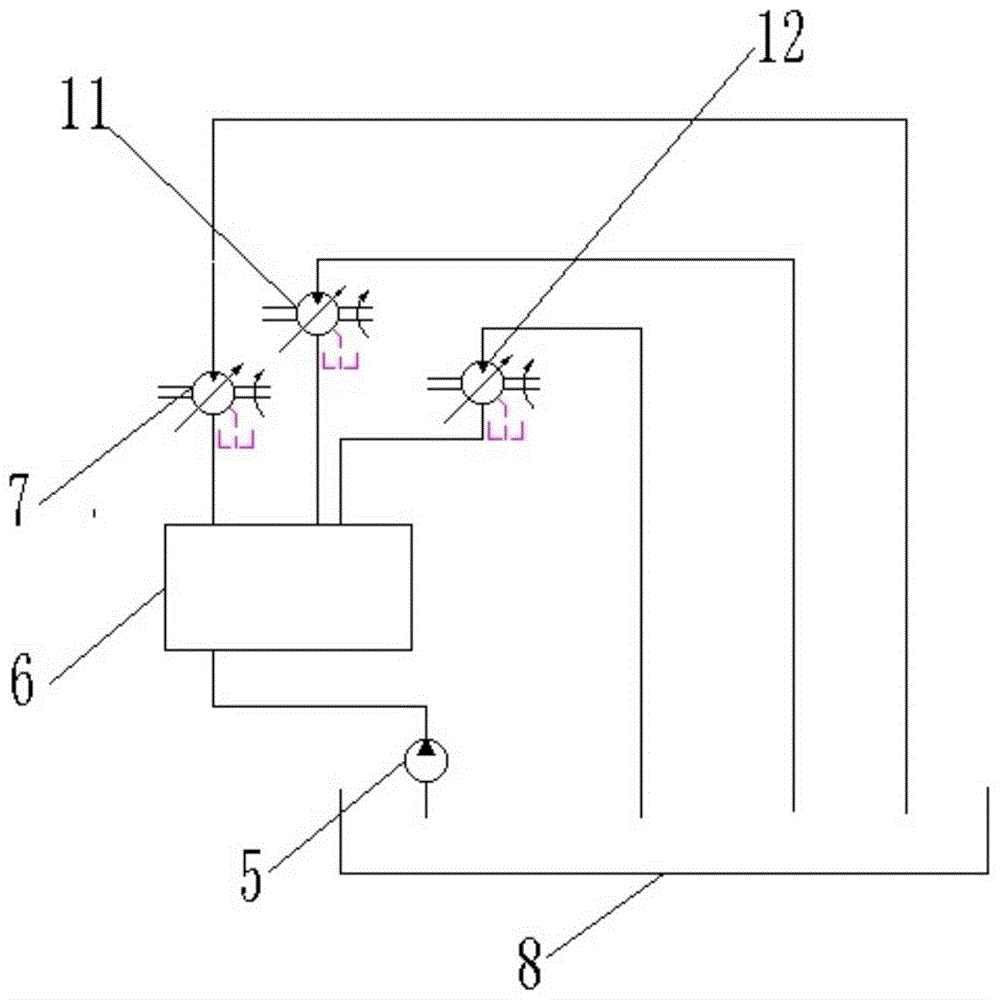

[0037] see Figure 1-12 , a boat-type laver harvester, including a hull and a power system, the hull includes a stern 1, a ship's side 2 and a deck 3, the deck 3 is provided with a laver harvesting device 4, and the power system includes sequentially communicated oil pumps 5. The four-way solenoid valve 6, the first hydraulic motor 7 and the oil tank 8, the first hydraulic motor 7 is a geared hydraulic motor, and the power system also includes a first propeller 9, a second propeller 10 and the first hydraulic motor The second hydraulic motor 11 and the third hydraulic motor 12 are arranged in parallel, the second hydraulic motor 11 and the third hydraulic motor 12 communicate with the four-way solenoid valve 6 respectively, and the first propeller 9 is arranged at the stern 1, the second propeller 10 is arranged at the side of the ship 2, the second hydraulic motor 11 drives the first propeller 9, and the third hydraulic motor 12 drives the second propeller 10; the second hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com