Automatic decontamination line for eggshell

A production line and poultry egg technology, applied in poultry farming, animal husbandry, application, etc., can solve problems affecting egg quality, poor shopping experience, lack of equipment for surface dirt, etc., to improve decontamination efficiency and ensure The effect of decontamination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

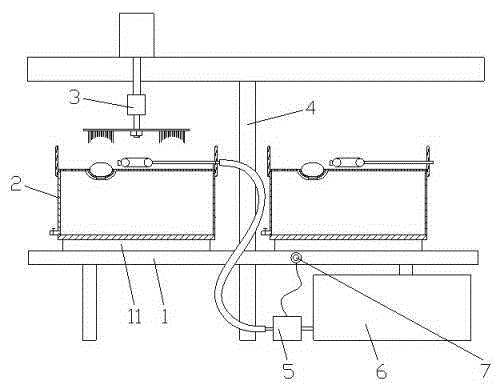

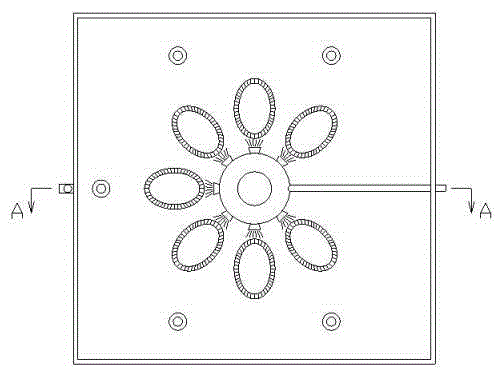

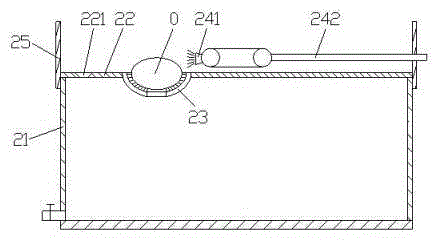

[0030] Example as Figure 1 to Figure 4 As shown, the automatic decontamination operation line of poultry eggs and eggshells in this embodiment includes an annular assembly line 1, a passive decontamination unit 2, an active decontamination head 3 and a support 4. More than two passive decontamination units 2 are placed, and the passive decontamination unit 2 includes a casing 21, a top cover 22, an egg tray 23, a spray washer and a water baffle 25, and the top of the casing 21 is provided with a top cover 22, The periphery of the top cover 22 is provided with a water retaining plate 25, and the box body 21 is provided with a sewage collection area. The top cover 22 is provided with an egg tray installation hole and a sewage recovery hole 221. The egg tray 23 is installed at the egg tray installation hole. The top of the tray 23 is open, and at least the bottom of the egg tray 23 is provided with drainage holes. The inner surface of the egg tray 23 is covered with upper side...

Embodiment 2

[0044] Example two such as Figure 5 to Figure 7 As shown, the difference between this embodiment and Embodiment 1 is: (1) In this implementation, in order to keep the environment inside the box body 21 relatively clean, the sewage collection area in the box body 21 is provided with a sewage collection box 26, an egg tray 23 The sewage discharge hole and the sewage recovery hole 221 are directly facing or communicated with the sewage inlet of the sewage collection box 26, and the casing 21 is provided with an opening for the sewage collection box 26 to enter and exit and for its sewage pipe to extend out; (2) In this implementation, The top cover 22 is provided with a water supply pipe passing hole, the water supply pipe 242 is installed below the top cover 22, and protrudes upwards from the surface of the top cover 22 through the water supply pipe passing hole, and the water supply pipe 242 is sealed between the water supply pipe passing hole; ( 3) In this implementation, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com