Axle-free water pressure circulation impulse starting filter

A filter and water pressure technology, applied in filtration and separation, moving filter element filters, separation methods, etc., can solve the problems of sludge or sundries accumulation, affecting filtration effect, and large operating energy consumption, to ensure filtration efficiency. , The effect of facilitating the collection of clean water and increasing the filter area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

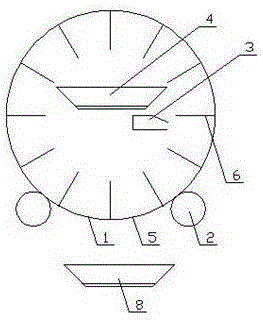

[0015] Example 1, such as figure 1 As shown, the drum 1 is welded by metal into a bracket structure, and the filter screen sheet 5 is connected with bolts on the drum 1, and four supporting wheels 2 are installed under the drum 1, so that under the support of the four supporting wheels 2, the The rotating force of the drum 1 can make the drum 1 rotate. This device is used for sewage filtration, so the drum 1 is provided with a sewage water inlet pipe 3 . The sewage flows into the drum 1 and is filtered through the filter mesh 5. In order to realize the continuous filtration of the device, a hydraulic impact plate 6 is provided on the inner wall of the drum 1, and the water outlet of the sewage inlet pipe 3 is located at the outlet where the water can impact the hydraulic impact. Plate 6 and the position where the hydraulic impact plate 6 can drive the drum 1 to rotate. The water outlet surface of the water inlet pipe 3 is the same as the axial length of the hydraulic impact pl...

Embodiment 2

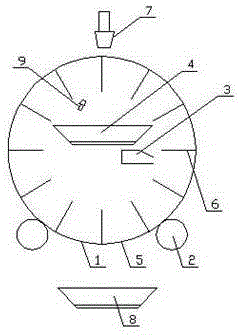

[0016] Example 2, such as figure 2 As shown, the drum 1 is welded by metal into a bracket structure, and a filter mesh is connected to the drum 1 by bolts, and four support wheels 2 are installed under the drum 1, so that under the support of the four support wheels 2, the drum 1 rotation force can make the drum 1 rotate, and this device is used for sewage filtration, so a sewage water inlet pipe 3 is provided in the drum 1. Sewage flows into the drum 1 and is filtered through the rate mesh. In order to realize the continuous filtration of the device, a hydraulic impact plate 6 is provided on the inner wall of the drum 1, and the water outlet of the sewage inlet pipe 3 is located at the outlet where the water can impact the hydraulic impact plate. 6 and the position where the hydraulic impact plate 6 can drive the drum 1 to rotate, and in order to achieve a better filtering effect, the water outlet surface of the water inlet pipe 3 is the same as the axial length of the hydra...

Embodiment 3

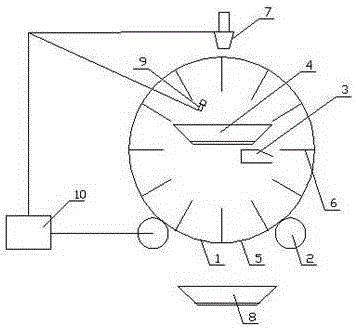

[0017] Example 3, such as image 3 Shown, on the basis of embodiment 1 or 2, on the supporting wheel 2, connect generator 10, impact plate flushing device 9 and screen sheet backwashing device 7 required energy is driven by generator 10, so just can The device is separated from the mains, increasing the field and area of use of the device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com