Rebar height adjustment device for submerged arc stud welding

A height adjustment device and height adjustment technology, applied in the direction of arc welding equipment, electrode support devices, welding rod characteristics, etc., can solve the problems of cumbersome efficiency and other problems, achieve the effect of convenient and fast adjustment, improve welding efficiency, and quickly and efficiently increase the height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

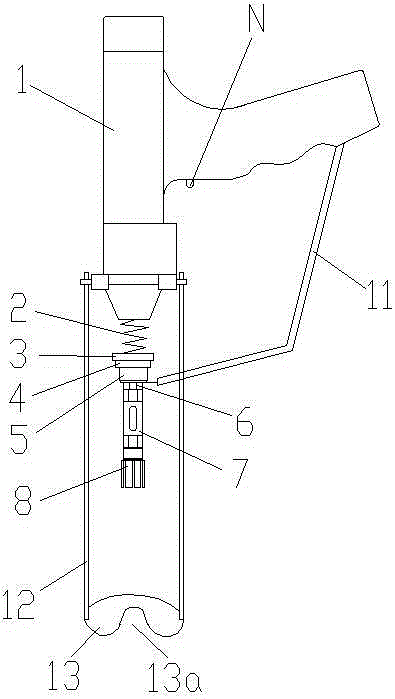

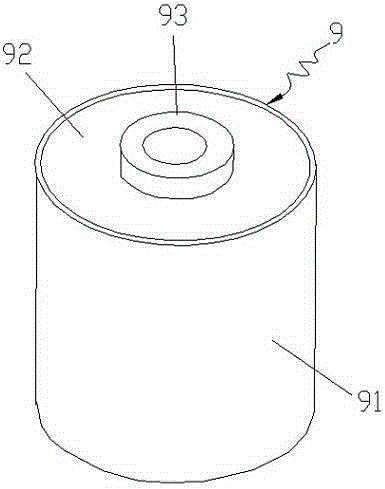

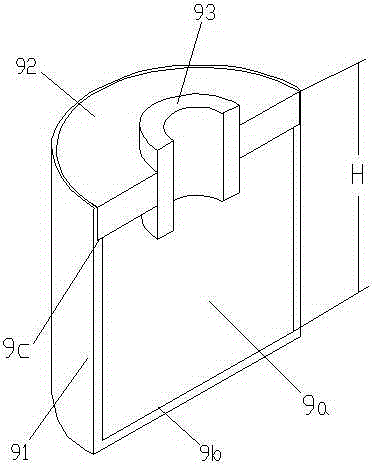

[0026] Figure 1 to Figure 8 It is a structural schematic diagram of the present invention.

[0027] The reference signs are: depth H, button switch N, welding torch 1, lifting handle 11, positioning rod 12, positioning plate 13, positioning notch 13a, pressure spring 2, pressure adjustment block 3, insulating gasket 4, chuck Screw rod 5, compression nut 6, height adjustment slider 7, upper slider 71, internal threaded hole 71a, radial threaded through hole 71b, sliding connection surface 71c, hexagonal cylinder 711, semi-cylindrical body 712, lower slider 72. Lower limit table 72a, adjustment chute 72b, connecting slide 721, hexagonal prism 722, round rod 723, locking handle 73, screw section 73a, cylindrical section 73b, connecting section 73c, lock shaft 731, rotary handle 732 , bearing pin 733, steel bar chuck 8, height adjustment box 9, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com