Welding technique for multi-joint heterogeneous material

A welding process and multi-joint technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of poor solder joint strength and sealing, complex welding process, and high overall cost, and achieve stable welding and process. The route is simple and reasonable, and there is no hidden leakage effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

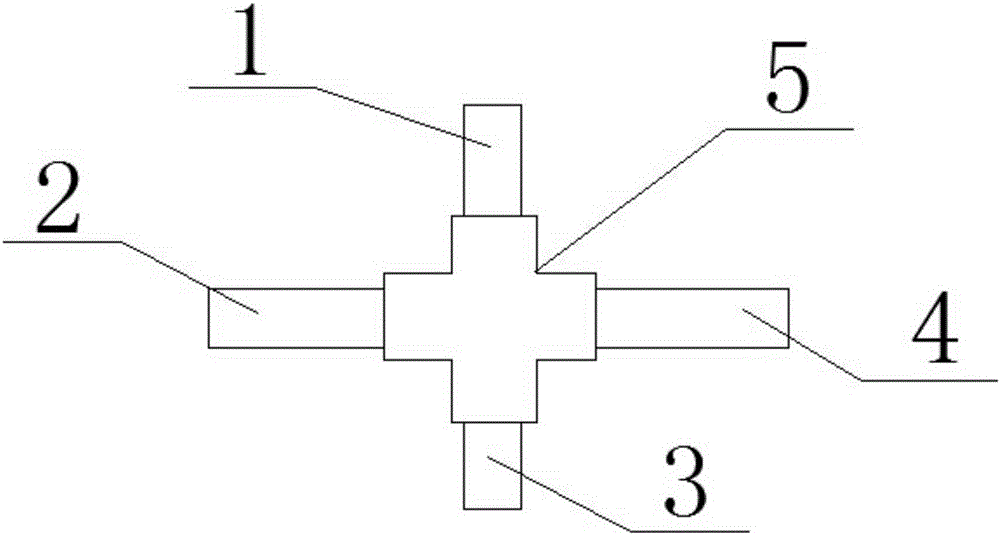

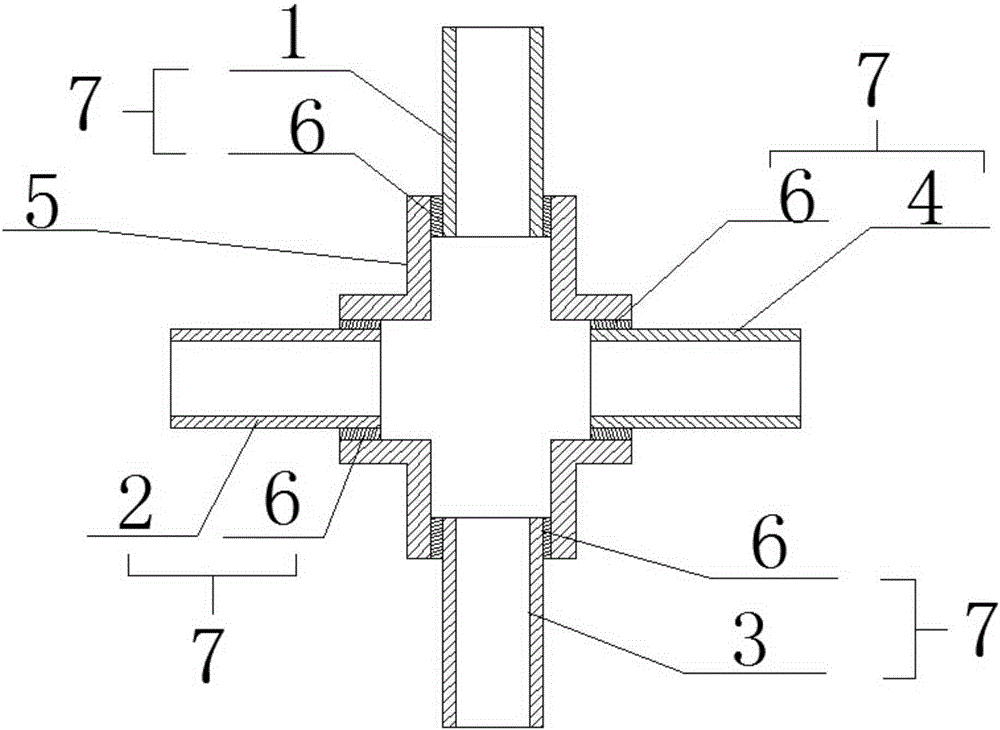

[0036] to combine figure 1 and figure 2 , a welding process of multi-joint dissimilar materials, specifically including four-joint base metal 5 and four connecting pipes, the four connecting pipes are respectively the first connecting pipe 1, the second connecting pipe 2, the third connecting pipe 3 and the fourth connecting pipe Connecting pipe 4, its welding process comprises the following steps:

[0037] (1) Select the joint material: according to the materials of the first connecting pipe 1, the second connecting pipe 2, the third connecting pipe 3 and the fourth connecting pipe 4, respectively select the joint material 6 that is compatible with the multi-joint base material 5 or seeps through. ;

[0038] (2) Build the joint assembly: weld the joint material 6 in the step (1) to the corresponding first connecting pipe 1, the second connecting pipe 2, the third connecting pipe 3 and the fourth connecting pipe 4 respectively, and make them respectively into a joint assem...

Embodiment 2

[0044] to combine figure 1 and figure 2 , a welding process of multi-joint dissimilar materials, specifically including four-joint base metal 5 and four connecting pipes, the four connecting pipes are respectively the first connecting pipe 1, the second connecting pipe 2, the third connecting pipe 3 and the fourth connecting pipe Connecting pipe 4, its welding process comprises the following steps:

[0045] (1) Select the joint material: according to the materials of the first connecting pipe 1, the second connecting pipe 2, the third connecting pipe 3 and the fourth connecting pipe 4, respectively select the joint material 6 that is compatible with the multi-joint base material 5 or seeps through. ;

[0046] (2) Build the joint assembly: weld the joint material 6 in the step (1) to the corresponding first connecting pipe 1, the second connecting pipe 2, the third connecting pipe 3 and the fourth connecting pipe 4 respectively, and make them respectively into a joint assembl...

Embodiment 3

[0052] combine figure 1 and figure 2 , a welding process of multi-joint dissimilar materials, specifically including four-joint base metal 5 and four connecting pipes, the four connecting pipes are respectively the first connecting pipe 1, the second connecting pipe 2, the third connecting pipe 3 and the fourth connecting pipe Connecting pipe 4, its welding process comprises the following steps:

[0053] (1) Select the joint material: according to the materials of the first connecting pipe 1, the second connecting pipe 2, the third connecting pipe 3 and the fourth connecting pipe 4, respectively select the joint material 6 that is compatible with the multi-joint base material 5 or seeps through. ;

[0054] (2) Build the joint assembly: weld the joint material 6 in the step (1) to the corresponding first connecting pipe 1, the second connecting pipe 2, the third connecting pipe 3 and the fourth connecting pipe 4 respectively, and make them respectively into a joint assembly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com