Tower crane position limiter structure

A technology of limiter and tower crane, applied in the field of machinery, can solve the problems such as the cantilever structure cannot control the moving distance, cannot effectively utilize work, reduce work efficiency, etc., and achieve the effect of being suitable for popularization, tight connection and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

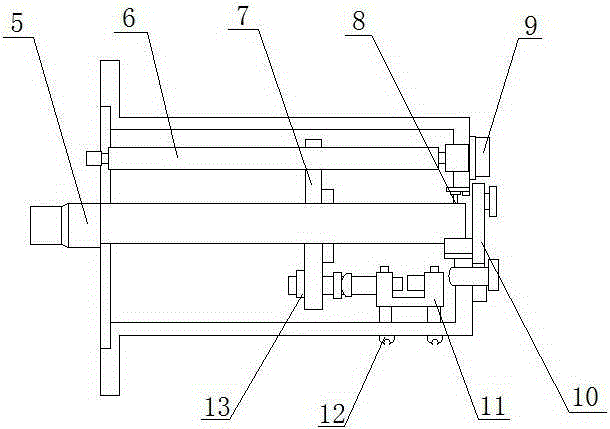

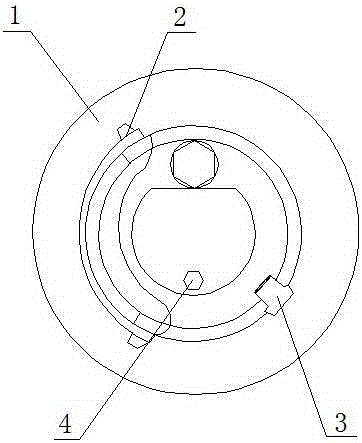

[0018] Example: such as Figure 1-2 As shown, a tower crane position limiter structure of the present invention includes a housing 1, a pressure plate 2, a bolt 3, a rubber ring 4, a screw rod 5, a guide rod 6, a moving nut 7, a bearing 8, a screw plug 9, an end cover 10, a limiter Bit switch 11, screw 12 and nut 13; Said housing 1 is equipped with a pressure plate 2 and said housing 1 is equipped with a guide rod 6; one side of said guide rod 6 is provided with a moving nut 7 located inside the housing 1 and the One end of the moving nut 7 is located on the side of the nut 13; a bolt 3 is installed at one end of the housing 1, and the top of the housing 1 is provided with a rubber ring 4 located on the side of the bolt 3; one end of the screw rod 5 is installed inside the end cover 10 And the end cover 10 is installed on one end of the casing 1 ; a limit switch 11 is arranged inside the casing 1 and the limit switch 11 is tightly connected by screws 12 .

[0019] As a techni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com