Wire rod hot tinning machine

A technology of hot-dip tinning machine and wire rod, which is applied in hot-dip plating process, metal material coating process, coating and other directions, which can solve problems such as wire rod deformation, achieve the effect of improving overall efficiency, improving excellent rate, and ensuring performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

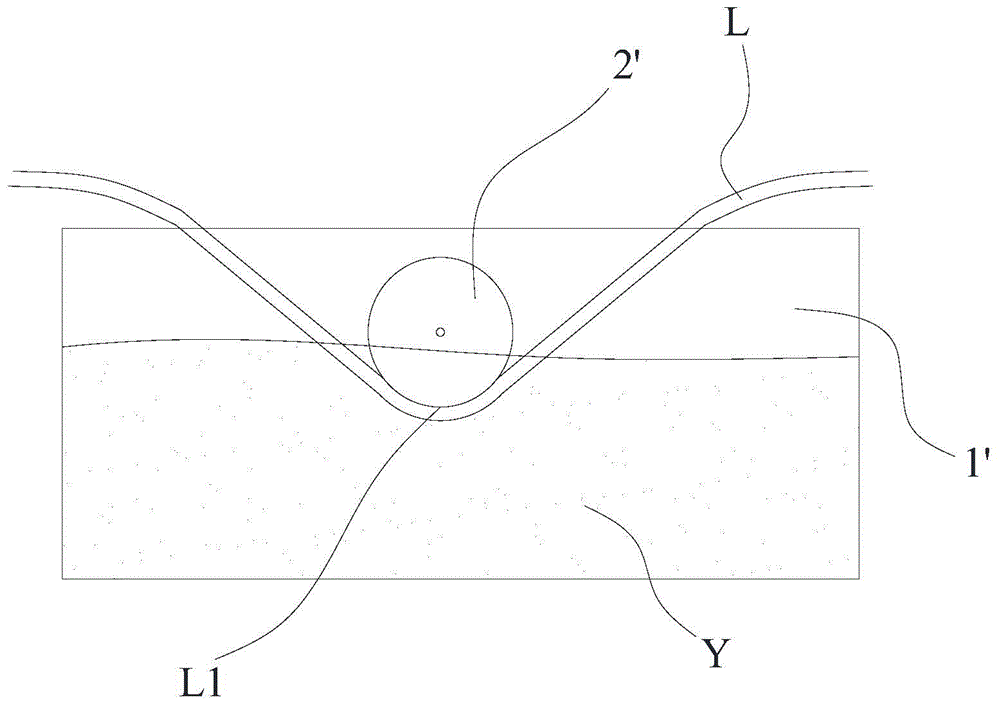

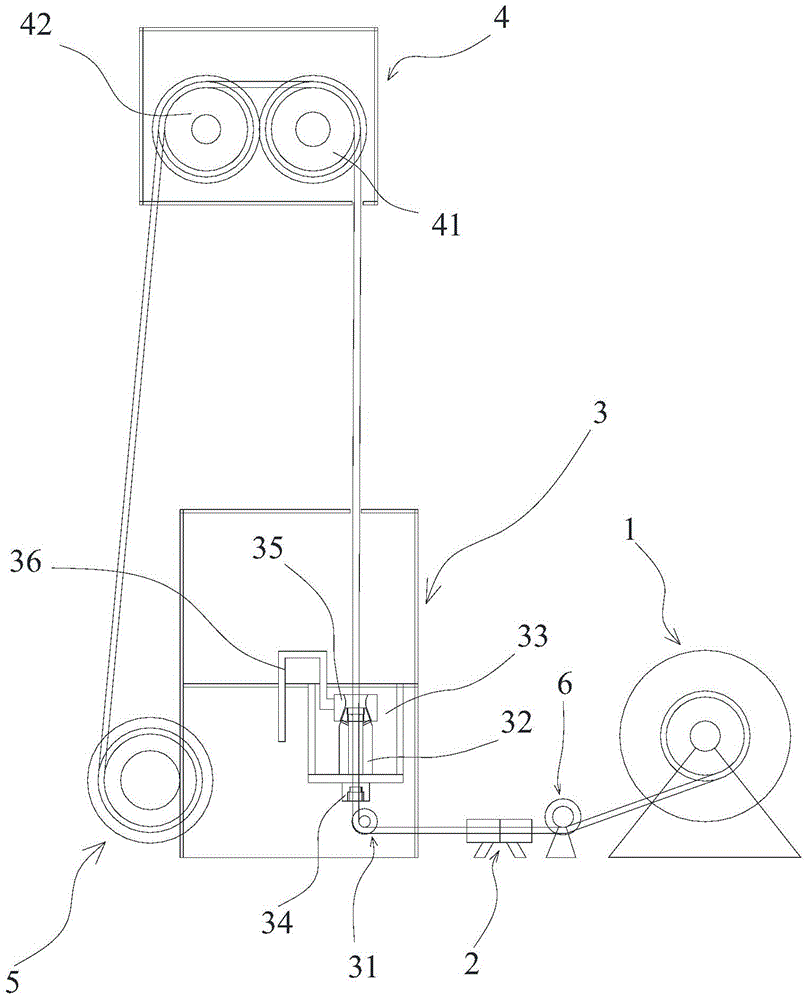

[0039] The wire rod hot-dip tinning machine provided by the present invention is explained in detail below in conjunction with the accompanying drawings. The wire rod in this example is an example of a coaxial cable, and other wire rods that need to be tinned can also be tinned on this equipment, such as figure 2 As shown, the wire rod hot-dip tinning machine described in this example includes a wire pay-off mechanism 1, a flux tank 2, a tinning box 3, a traction mechanism 4 and a wire take-up mechanism 5;

[0040] The pay-off mechanism 1 is used to release the wire L to the flux tank 2;

[0041] The flux tank 2 is used to receive the wire L released by the pay-off mechanism 1, and release the wire L wrapped with flux to the tinning box 3;

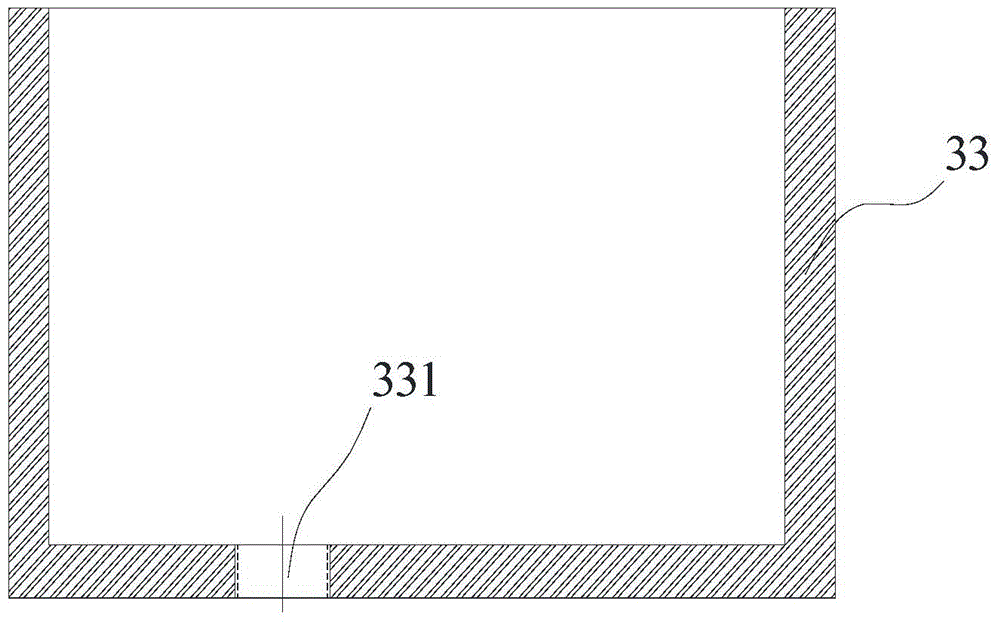

[0042] Described tinning box 3 inside is provided with tin tank 33, is provided with tinned tube 32 in described tin tank 33; Figure 4 shown);

[0043] Also provided with a variable guide wheel 31, the variable guide wheel 31 is used t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com