Method for preparing single-phase nanocrystal Co-Ni-W alloy coating through electrodeposition

An alloy coating, co-ni-w technology, applied in the field of metal surface treatment, can solve problems such as deterioration of coating corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Take a number of cold-rolled low-carbon steel plates of 10×20×1.5mm, polish the surface with metallographic sandpaper, wash them with absolute ethanol and acetone in sequence, dry them, and put them in a desiccator for later use. The treated cold-rolled low-carbon steel plate will serve as a substrate for electrodeposition.

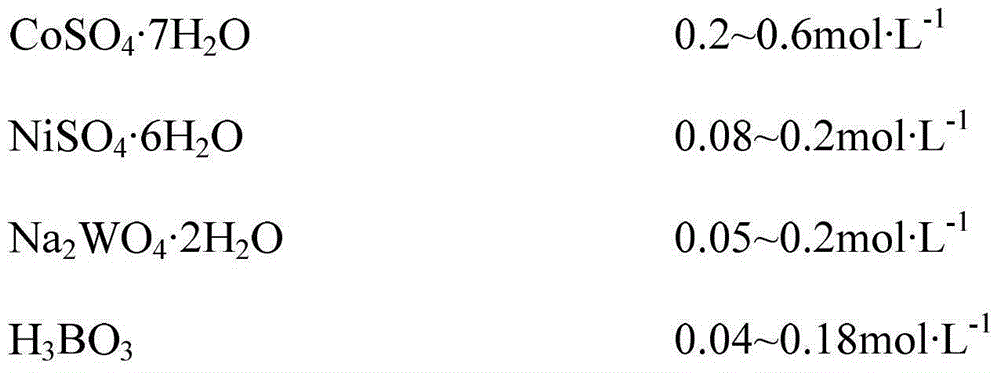

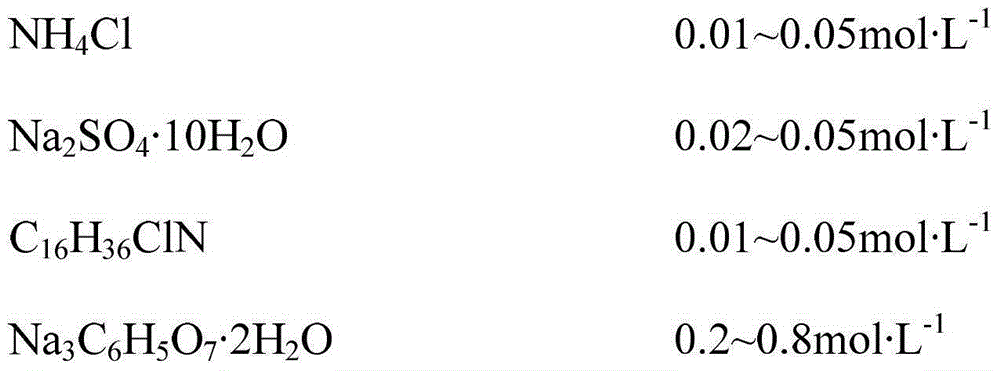

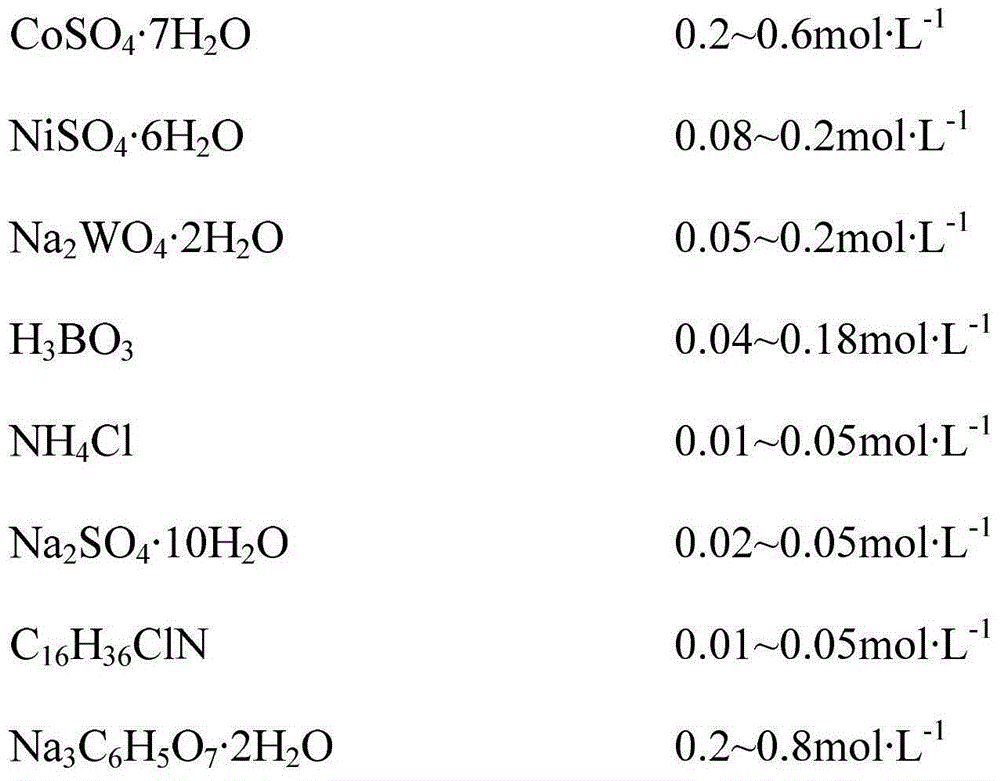

[0033] Use deionized water to prepare the plating solution, the composition of the plating solution is: CoSO 4 ·7H 2 O0.4mol L -1 , NiSO 4 ·6H 2 O0.1mol L -1 , Na 2 WO 4 2H 2 O0.1mol L -1 , H 3 BO 3 0.06mol·L -1 , NH 4 Cl0.01mol L -1 , Na 2 SO 4 10H 2 O0.03mol L -1 , C 16 h 36 ClN0.02mol L -1 , Na 3 C 6 h 5 o 7 2H 2 O0.2mol L -1 . The pH value of the plating solution was adjusted to 7.5, and then the plating solution was left to age for 36 hours.

[0034] The previously pretreated cold-rolled low-carbon steel plate was used as the cathode, and the platinum sheet was used as the anode. The distance between the cathode and...

Embodiment 2

[0038] The cold-rolled low-carbon steel plate was processed according to the method of Example 1.

[0039] Use deionized water to prepare the plating solution, the composition of the plating solution is: CoSO 4 ·7H 2 O0.5mol L -1 , NiSO 4 ·6H 2 O0.15mol L -1 , Na 2 WO 4 2H 2 O0.2mol L -1 , H 3 BO 3 0.06mol·L -1 , NH 4 Cl0.02mol L -1 , Na 2 SO 4 10H 2 O0.03mol L -1 , C 16 h 36 ClN0.03mol L -1 , Na 3 C 6 h5 o 7 2H 2 O0.2mol L -1 . Adjust the pH value of the plating solution to 8, and then leave the plating solution to age for 36 hours.

[0040] The previously pretreated cold-rolled low-carbon steel plate was used as the cathode, and the platinum sheet was used as the anode. The distance between the cathode and the anode was 5 cm, the electrodeposition temperature was 40 ° C, and the average cathode current density was 120 mA cm -2 , the duty cycle of the pulse current is 60%, the pulse frequency is 1200Hz, the ultrasonic power is 120W, the ultrasonic f...

Embodiment 3

[0044] The cold-rolled low-carbon steel plate was processed according to the method of Example 1.

[0045] Use deionized water to prepare the plating solution, and the composition of the plating solution is the same as in Example 1. The pH value of the plating solution was adjusted to 7.5, and then the plating solution was left to age for 36 hours.

[0046] The previously pretreated cold-rolled low-carbon steel plate was used as the cathode, and the platinum sheet was used as the anode. The distance between the cathode and the anode was 5 cm, and the electrodeposition temperature was 40°C.

[0047] The average cathode current density, pulse current duty cycle, pulse frequency, ultrasonic power, ultrasonic frequency, and electrodeposition time of the electrodeposition process are the same as in Example 2.

[0048] The insulation heat treatment method is with embodiment 1.

[0049] The analysis, characterization and performance testing methods of the samples are the same as th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com