Intelligent direct-buried integrated prefabricated pump station long in service life

A direct-buried, long-term technology, applied in the direction of waterway systems, drainage structures, water supply devices, etc., can solve the problems of long construction period, poor coordination, low degree of integration, etc., to improve anti-corrosion ability, increase service life, The effect of high degree of integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

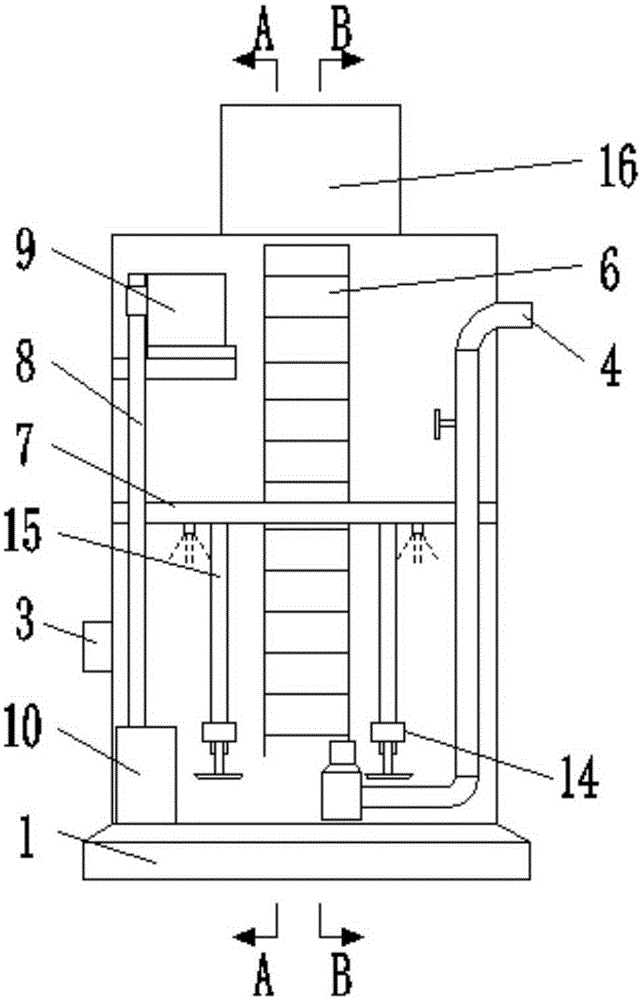

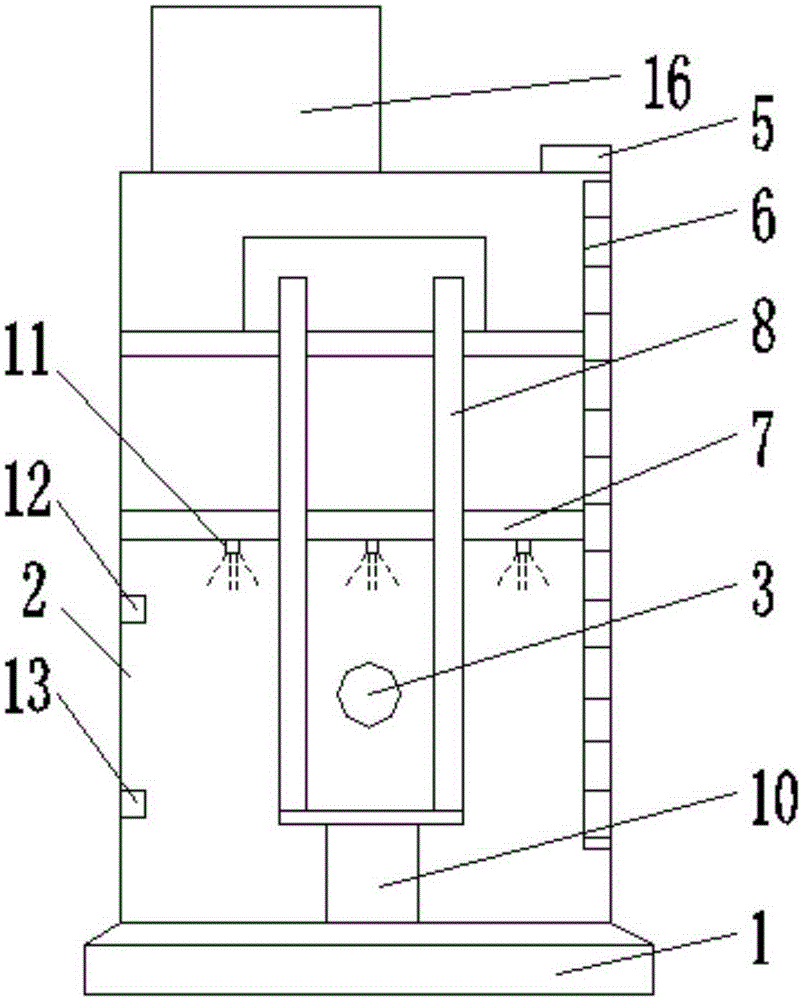

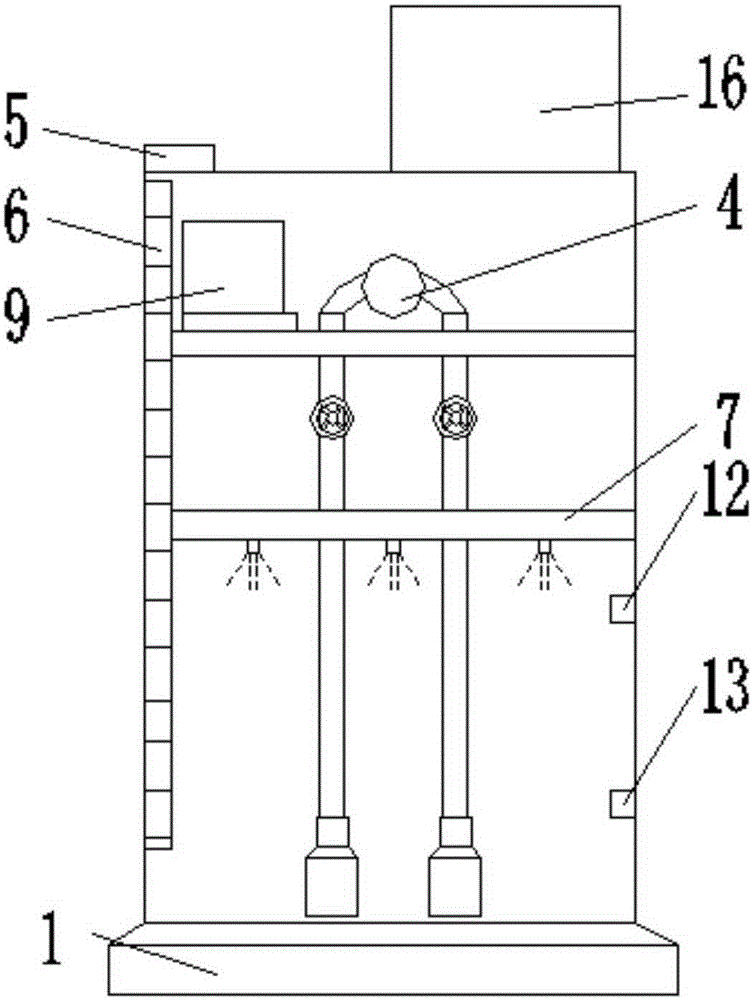

[0026] The invention relates to an intelligent direct-buried integrated prefabricated pumping station with a long service life. The pumping station is a tank body 2 with a base 1. The tank body 2 includes a lower water-holding area and an upper operating area. The body 2 is provided with a water inlet pipe 3 and a water outlet pipe 4, the water inlet pipe 3 is located outside the water holding area, the water outlet pipe 4 is located outside the operating area, the bottom of the tank body 2 is provided with a pumping device with an output end connected to the water outlet pipe 4, and the output end of the pumping device A switch device is provided at the position in the operating area. The upper end of the tank body 2 is provided with a manhole 5 and a personnel lifting passage 6 connected thereto. A service platform adjacent to the personnel lifting passage 6 is provided at the bottom of the operating area. A corrosion-resistant layer is provided, and the corrosion-resistant l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com