Composite steam hydrophobic valve for continuous drainage

A steam trap and composite technology, applied in steam traps, mechanical equipment, etc., can solve the problems of short service life, waste of energy, waste of steam, etc., and achieve the effect of avoiding steam leakage, long service life and wide adjustment range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

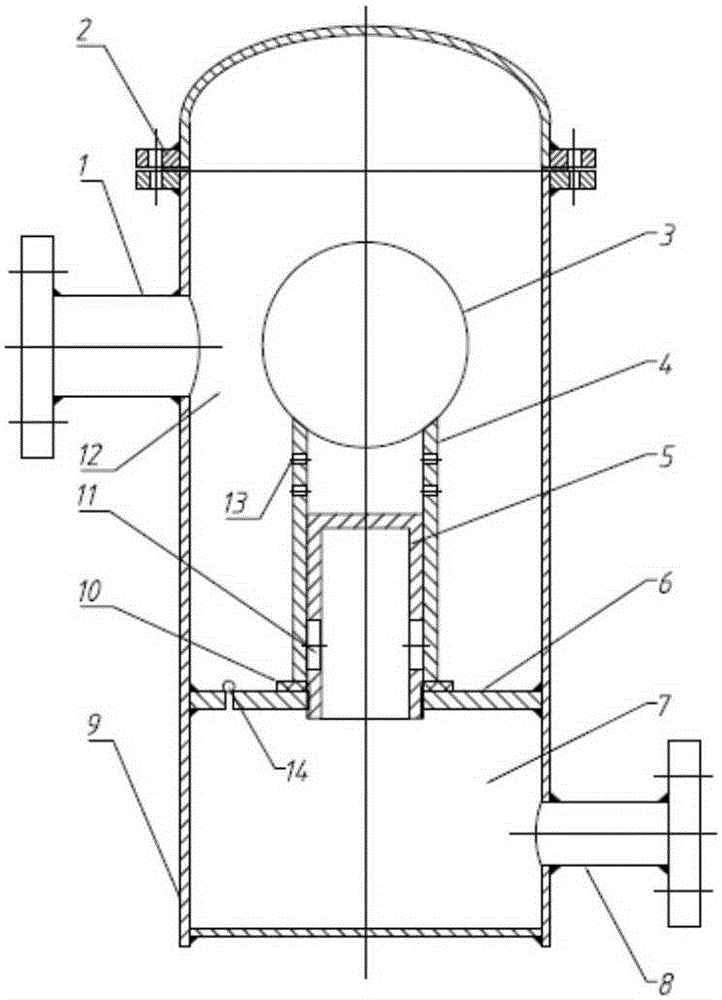

[0033] Such as figure 1 Shown is a schematic diagram of the structure of a composite steam trap for continuous drainage of the present invention.

[0034] The following describes the scheme through specific implementations and the accompanying drawings:

[0035] A composite steam trap for continuous drainage. The steam trap includes a large hydrophobic functional module A and a small hydrophobic functional module B. The upper end of the valve core A is connected with the hydrophobic functional module A, and the valve body 9 is provided with There is a steam-water mixture inlet 1 and a condensed water outlet 8. The valve body 9 is fixedly connected with a valve seat 6. The valve seat 6 separates the inner cavity of the valve body 9 into an upper cavity 12 and a lower cavity 7. The valve seat 6 is fixed with a guide rail 5, the valve core A is installed in the cavity of the valve body 9 through the guide rail 5, the guide rail 5 adopts a hollow structure, the soda water mixture inle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com