Remote self-diagnosis system and self-diagnosis method of complex dynamic weighing sensor network

A self-diagnostic system, dynamic weighing technology, applied in the direction of weighing equipment testing/calibration, weighing, measuring devices, etc., can solve problems such as reducing traffic rate, waste of resources, major traffic accidents, etc., to save time, cost and money cost, saving construction resources, and reducing the effect of construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

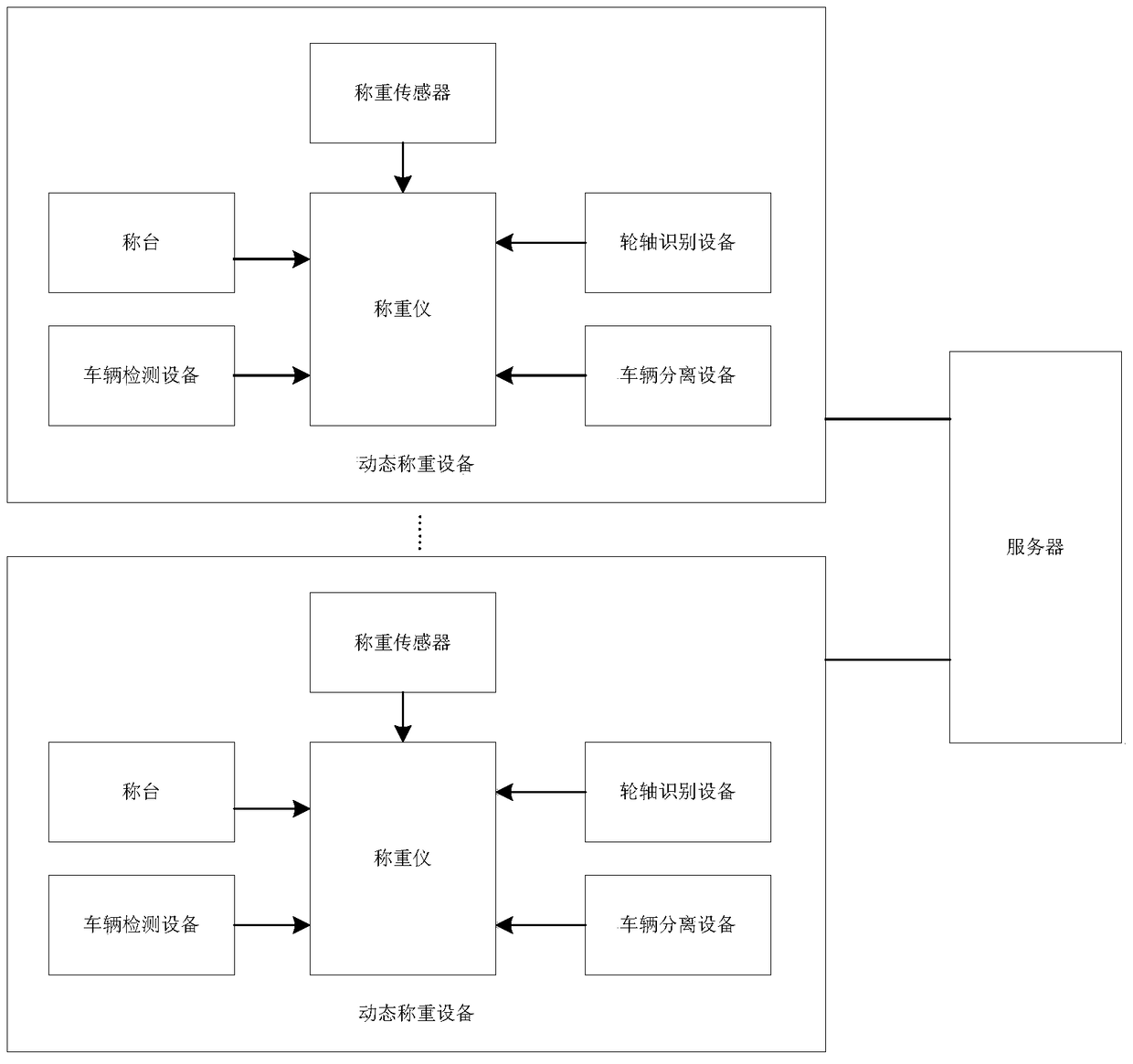

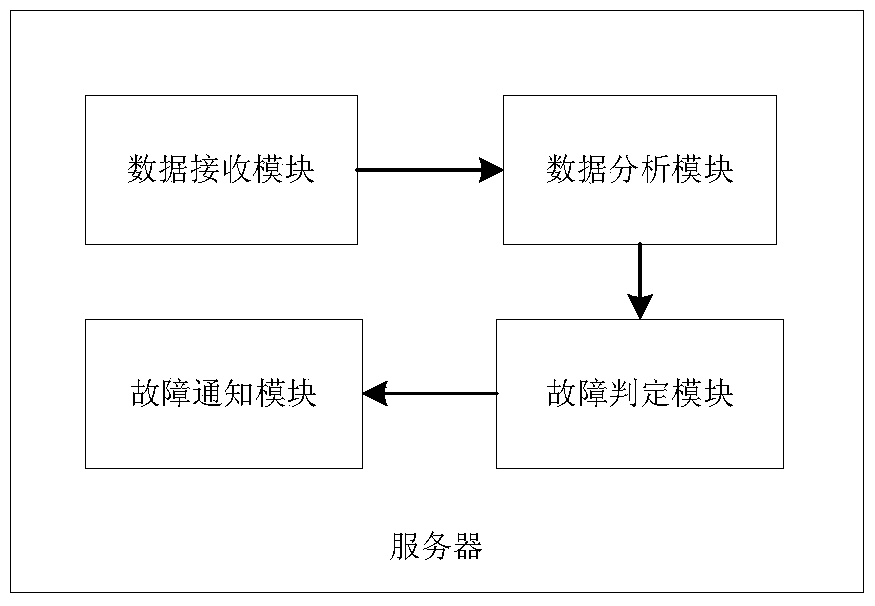

[0030] Such as figure 1 , as shown in 2, the remote self-diagnosis system under the complex dynamic weighing sensor network of the present invention includes dynamic weighing devices and remote servers respectively located in multiple weighing areas, and the dynamic weighing devices are used for dynamic weighing Weigh and record the working status information of the equipment, and upload the working status information of the equipment to the server, and the server is used to receive and process the working status information of the equipment, and judge whether the dynamic weighing equipment is faulty. The remote self-diagnosis system makes full use of the existing dynamic weighing area, and sends data to the server after the vehicle completes all dynamic weighing. It does not need to set up a server in each dynamic weighing area, effectively saving construction resources and reducing construction costs. The dynamic weighing equipment records the working status information of e...

Embodiment 2

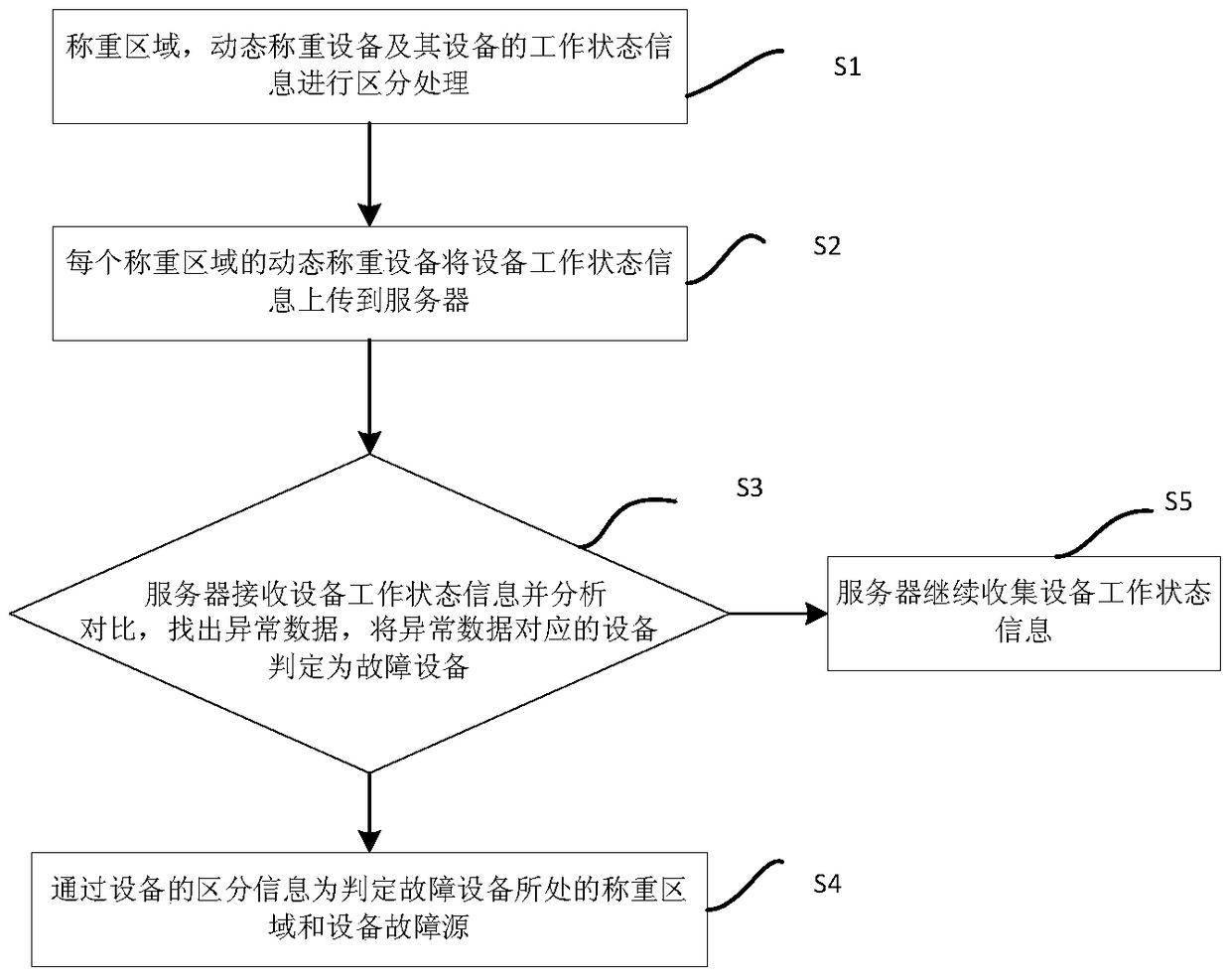

[0037] Such as image 3 As shown, the present invention also includes a remote self-diagnosis method under a complex dynamic weighing sensor network, specifically comprising the following steps:

[0038] S1: Each vehicle detection equipment, weighing platform, vehicle separation equipment, weighing instrument and the working status information presented by each equipment in the dynamic weighing equipment of each weighing area are processed in a differentiated manner. Distinguish the weighing area and the various equipment of the dynamic weighing equipment, so that the location of the faulty equipment can be traced later. The differentiated processing adopts the method of node numbering. Each weighing area and each device has a corresponding number to distinguish it. Through the numbering, a certain device in a certain weighing area can be found correspondingly. Of course, other methods for distinguishing weighing areas and equipment can also be used in specific implementation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com