Shale gas content tester and testing method thereof

A shale gas and tester technology, applied in the field of exploration and measurement, can solve the problems of insufficient measurement accuracy, low measurement accuracy, large gas flow rate measurement error, etc., and achieves improved precision, high data accuracy, and good measurement linearity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

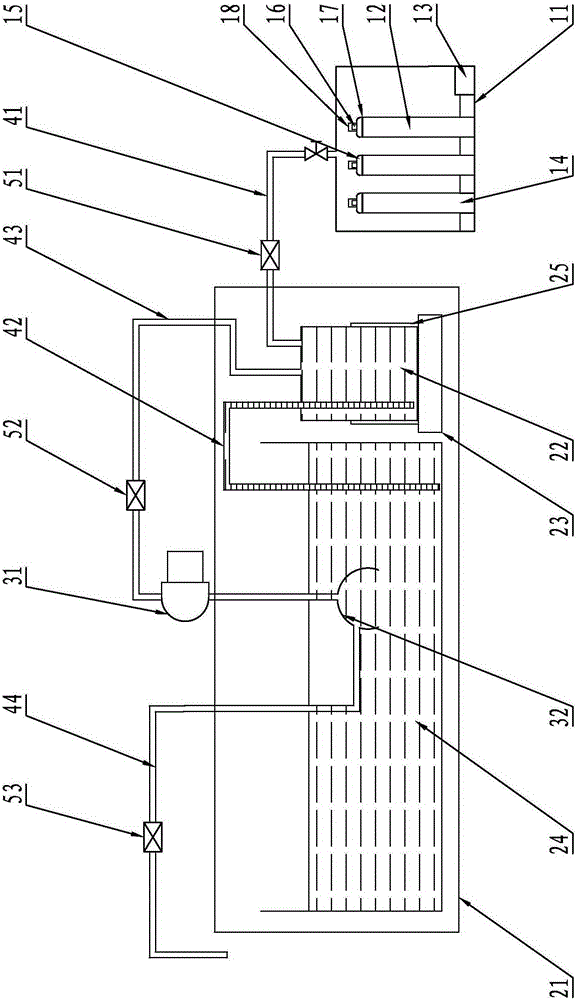

[0055] Such as figure 1 As shown, the shale gas content tester of the present invention includes a sample analysis device, a real-time measurement device, an exhaust device, and an acquisition and control system. The analysis device is connected to the real-time measurement device through the first metal pipeline 41, and the analysis device includes a constant temperature water bath. 11 and analysis tank 12, the analysis tank 12 is placed in the constant temperature water bath 11, the number of analysis tanks 12 is 4-6, and the constant temperature water bath 11 is provided with a structure that matches the shape of the bottom of the analysis tank 12, and the analysis tank 12 is placed Fixing is implemented in the fitting structure, a temperature transmitter 13 is arranged in the constant temperature water bath 11, and the analysis tank 12 includes a tank body 14, a tank cover 15, a quick connector 16, an O-shaped sealing ring 17 and a protective cover 18, and the tank body 14 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com