Heparin sodium production process elution monitoring method

A technology of heparin sodium and eluent, which is applied in the direction of phase influence characteristic measurement, etc., can solve the problems of time-consuming and laborious manual operation, failure to monitor the whole process of elution, drug running, etc., so as to avoid production accidents, save manpower and material resources, and avoid The effect of cumbersome steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

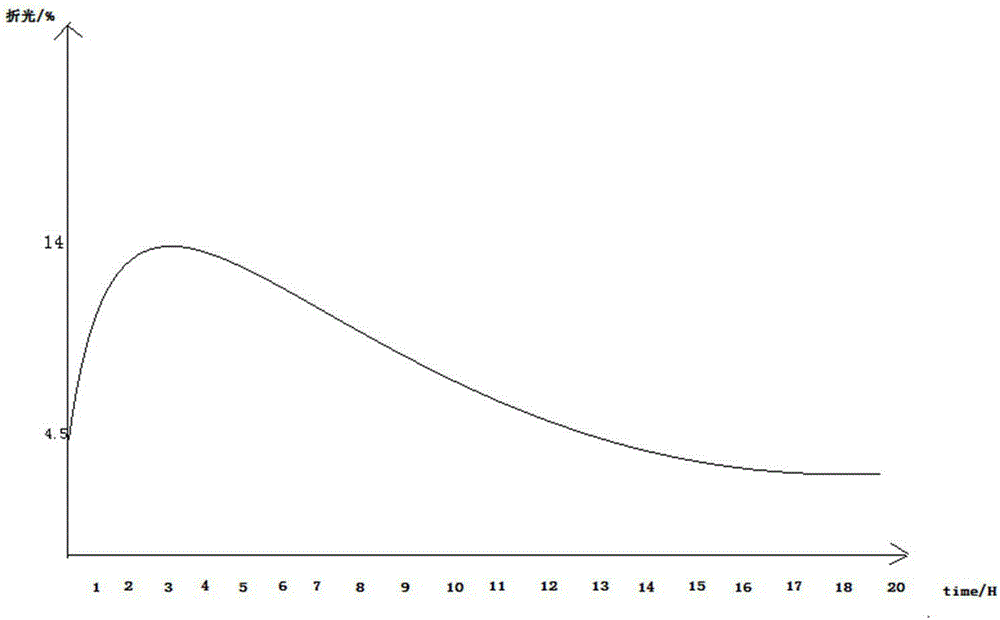

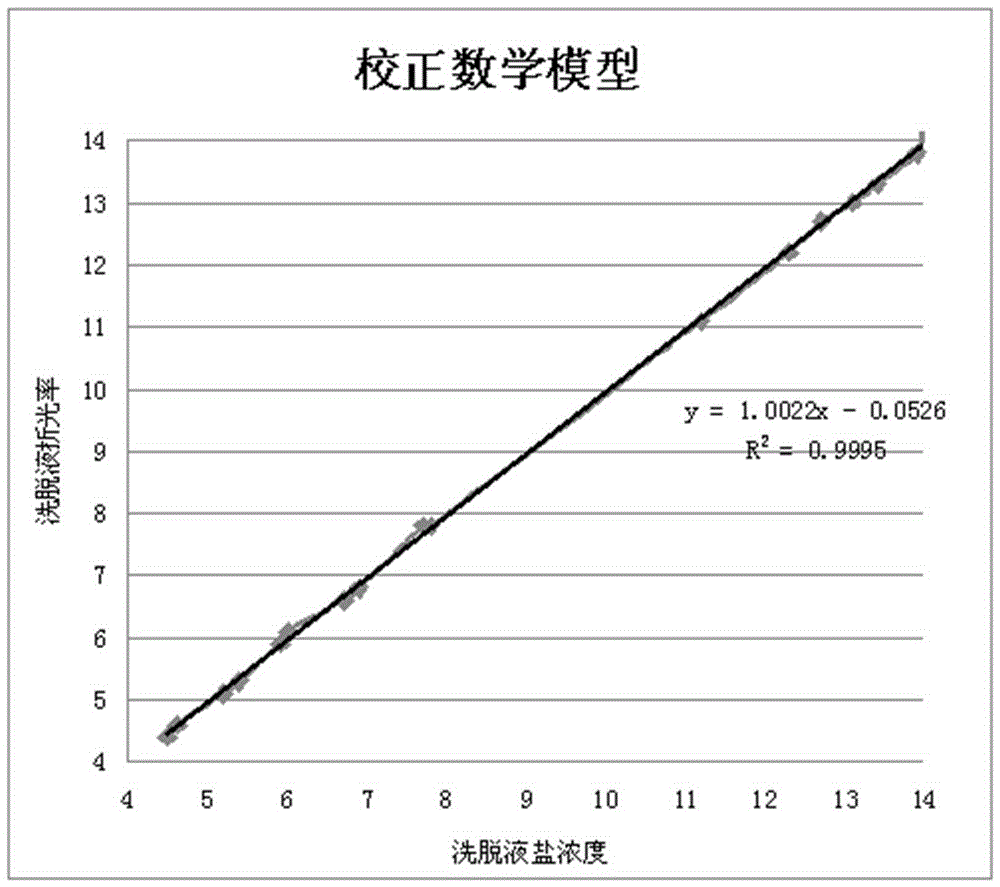

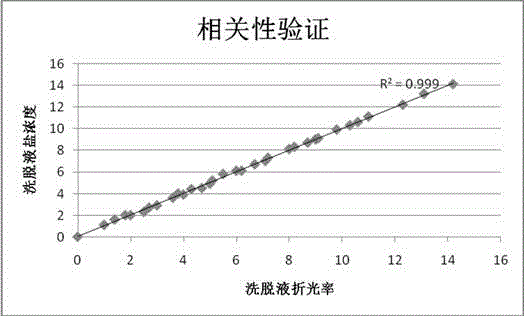

[0022] Real-time monitoring of the elution process of heparin sodium using the differential detection monitoring system (RI-201H):

[0023] A. First prepare 2.7% and 12% saline solution (w / w) with purified water and injection grade sodium chloride, among which 1200L of 2.7% saline solution and 1000L of 12% saline solution. Take 1000ml of 12% saline solution for ultrasonic dissolution for 30min and filter it with suction as a standard solution for differential detection to calibrate the baseline.

[0024] B. Heparin sodium elution process steps at room temperature: use 12% (w / w) NaCl solution 1000L to elute the elution column, and when the increase in the refractive index of the C column effluent reaches 4.3%, let it stand for 2 hours , and then start elution, collect the eluent into the glass reactor 3 and then use 1200L of 2.7% (w / w) NaCl solution to squeeze the resin column, when the refractive index of the outlet effluent of the eluting column is less than 4.0 %, stop coll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com