Aeroengine ground stand test state monitoring system

An aero-engine and bench test technology, which is applied in general control systems, control/adjustment systems, computer control, etc., can solve the problems that manual records cannot meet the requirements of aero-engine experiments, and achieve communication stability and prevent data packet loss , Measurement and control accuracy and high speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so as to define the protection scope of the present invention more clearly.

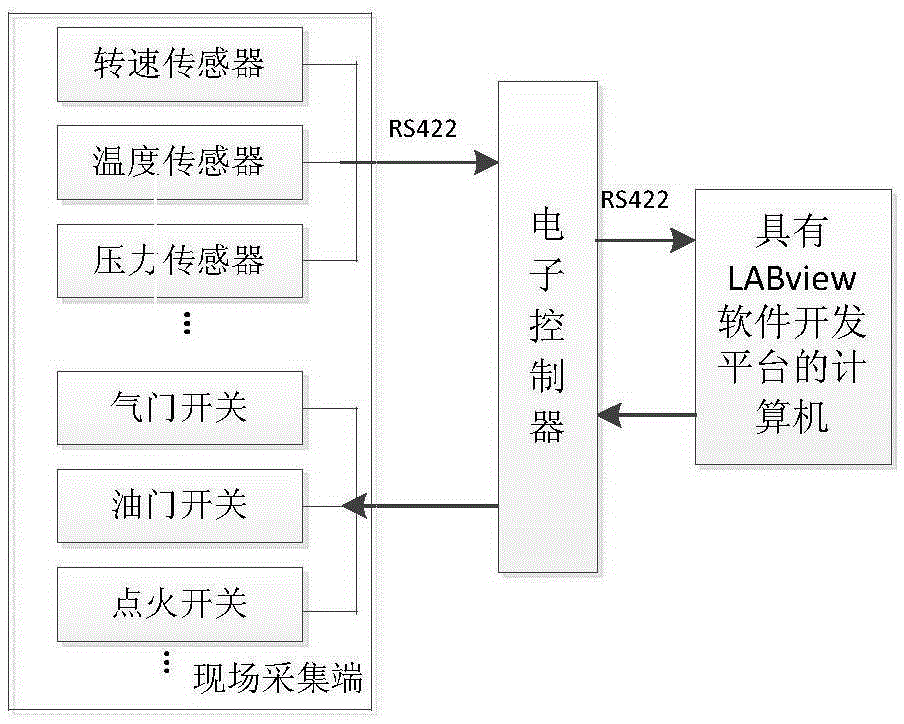

[0021] figure 1 The overall structure diagram of the aero-engine ground bench test status monitoring system of the present invention is given. The system includes a serially connected field data acquisition terminal, an electronic controller, and a computer with a labview development platform as a host computer.

[0022] The on-site data acquisition terminal includes at least one speed sensor, at least one temperature sensor, and at least one pressure sensor, wherein the speed sensor detects the engine rotor speed, the temperature sensor detects the intake air temperature of the engine inlet port and the outlet temperature of the tail nozzle, and the pressure sensor detects the engine rotor speed. Check the inlet and outlet pressure of the compressor.

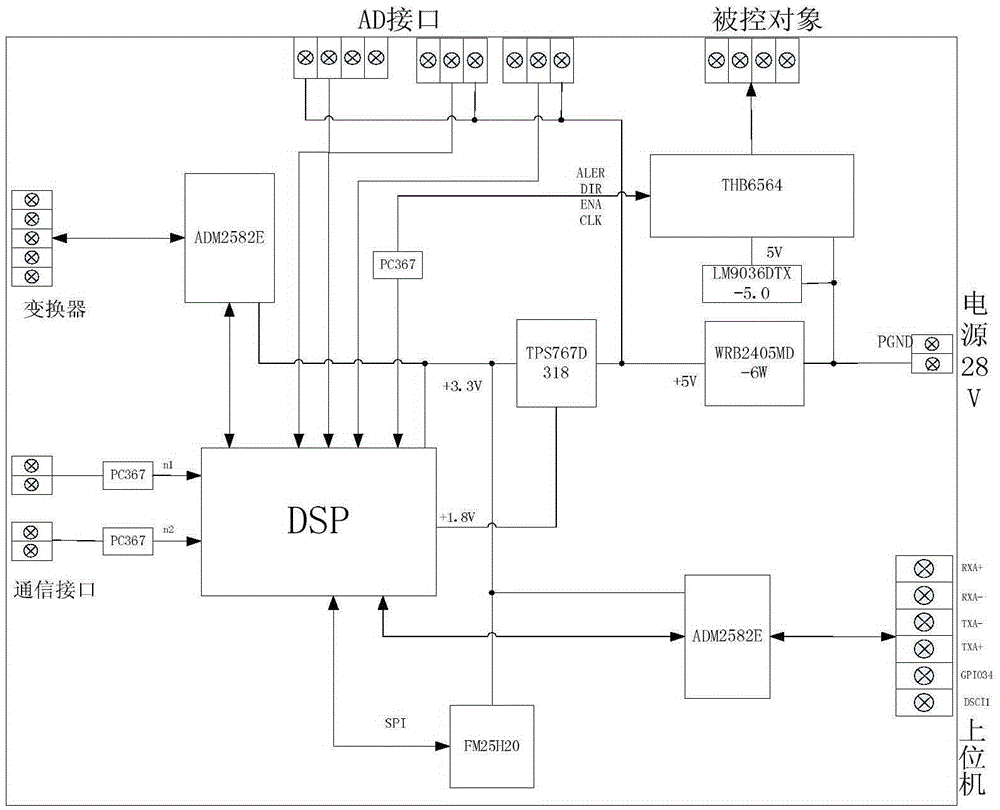

[0023] figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com