Air blade and wet processing apparatus having the same

An air knife and the same technology, applied in the field of air knife and wet processing device with air knife, can solve the problems of water residue in silicon wafers, no fan, and increased debris rate, etc., to prevent uneven force, and to design airflow structure. reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

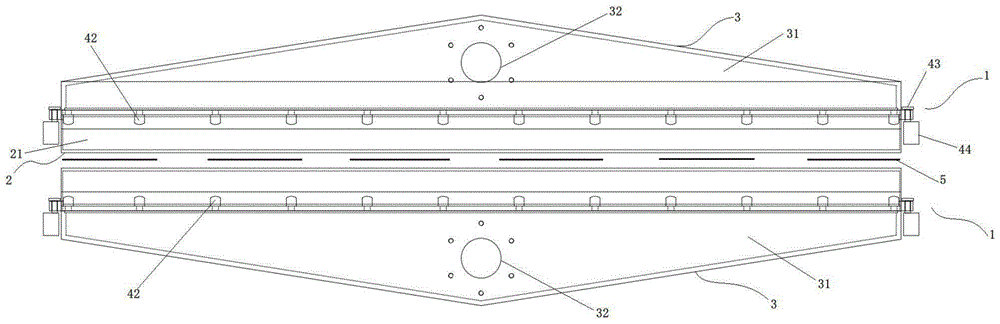

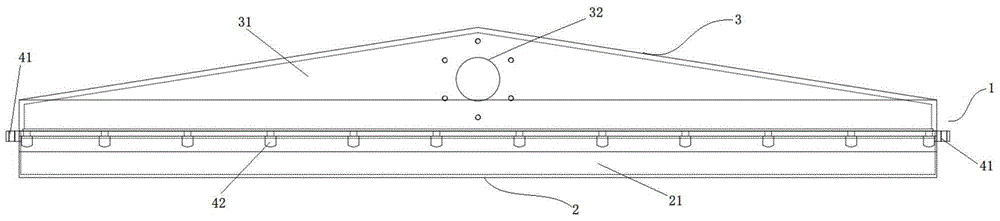

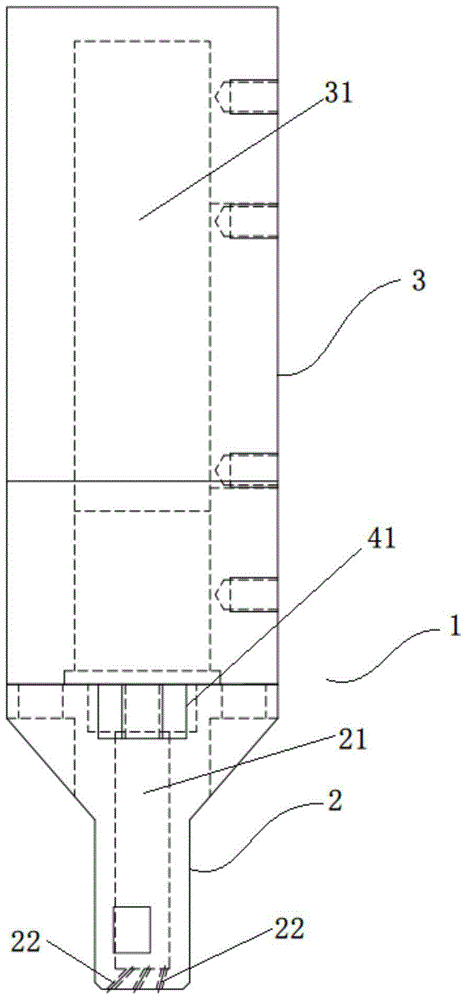

[0026] Example 1: figure 1 It is the front view of the air knife provided by the embodiment of the present invention, figure 2 It is the left view of the air knife provided by the embodiment of the present invention. It can be clearly seen from the figure that the air knife provided by this embodiment includes an air inlet part 3 and an air outlet part 2. The air inlet part 3 has an inlet The air inlet housing of the air chamber 31, the air outlet part 2 is an air outlet housing with an exhaust chamber 21 inside, and the air inlet chamber 31 of the air inlet housing communicates with the exhaust chamber 21 of the air outlet housing , the surface of the air inlet shell is provided with an air inlet 32, and the air outlet part 2 is provided with a plurality of exhaust channels 22, each exhaust channel 22 is inclined to the horizontal plane, and the sandwich between the exhaust channel 22 and the horizontal plane Angle is the inclination angle of the exhaust channel 22, and the...

Embodiment 2

[0041] Embodiment 2: Different from the air knife structure in Embodiment 1, the number of the exhaust channel groups is four, and the distance between adjacent exhaust channels 22 in the same exhaust channel group is kept constant. Under the premise that the corresponding exhaust channels 22 in the four exhaust channel groups overlap in the horizontal position, the silicon wafer will be blown more comprehensively and evenly. Similarly, according to the width of the air knife and two adjacent exhaust air The spacing of the channel groups can also increase or decrease the number of exhaust channel groups adaptively, without limiting the number of exhaust channel groups to three or four.

[0042] As a preferred arrangement, the included angles between the exhaust channel 22 and the end surface of the exhaust part 23 in the four exhaust channel groups from near to far from the inclined side are 40°, 53°, and 66° respectively. and 80°, but the present invention is not limited to s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com