Alternating-current LED light source

A technology of LED light source and LED chip, which is applied in the direction of electrical components, electric solid devices, circuits, etc., can solve the problems of damage to the driving power supply, large installation space, and overall unsightly appearance, so as to reduce the occupied space, reduce the volume, and save energy. Effect of Material Cost and Labor Installation Cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

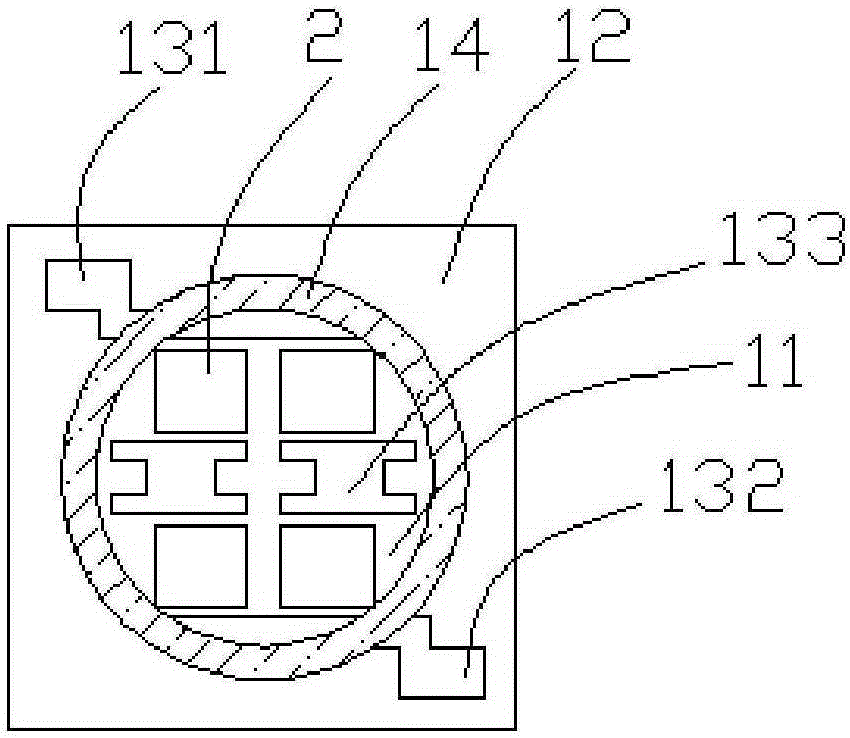

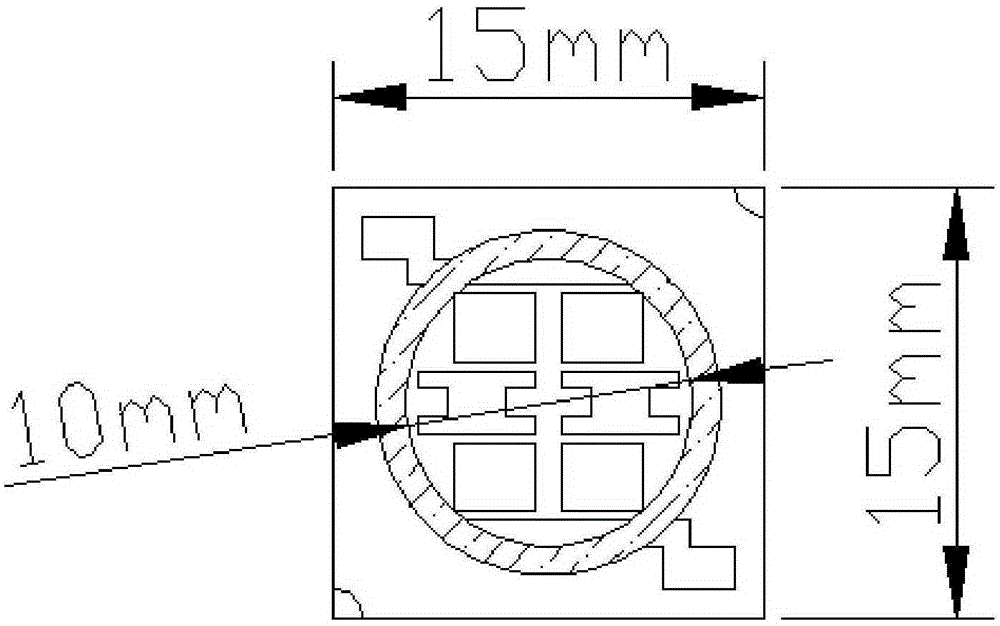

[0020] Such as figure 1 As shown, an AC LED light source includes a substrate and several groups of AC LED chips 2; the substrate includes an alumina substrate 11, an insulating layer 12, and a conductive layer 13 from bottom to top. The substrate 1 also includes an AC LED light source die-bonding block. The insulating layer 12 provided by the present invention is a ceramic insulating layer, and the conductive layer 13 is provided with a positive electrode 131 , a negative electrode 132 and a series circuit 133 ; the series circuit 133 is located in the die-bonding block. The insulating layer 12 is fixed on the alumina substrate 11 around the AC LED light source die-bonding block; each group of AC LED chips is connected in series thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com