Single-core structure of lithium battery, core assembly and core module

A cell pack and lithium battery technology, applied in battery pack parts, secondary batteries, structural parts, etc., can solve problems such as low contact resistance, and achieve the effect of ensuring connection quality, convenient connection, and improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

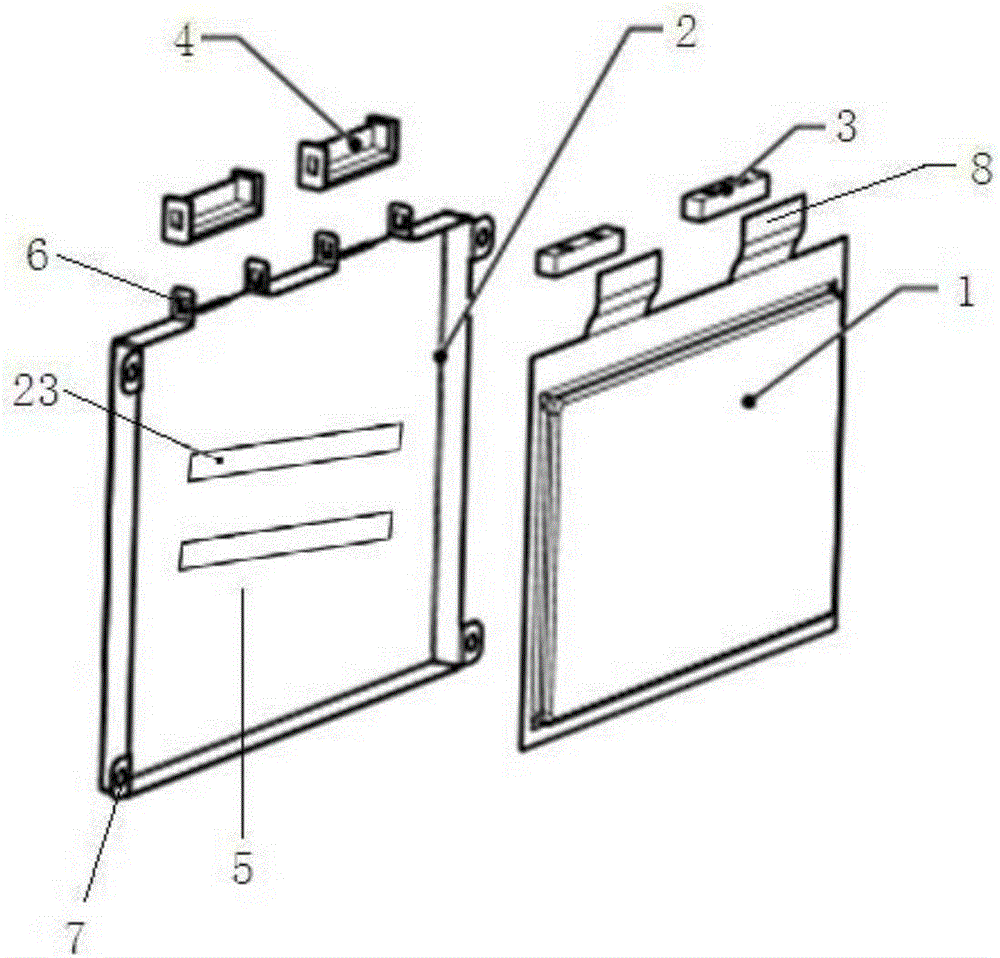

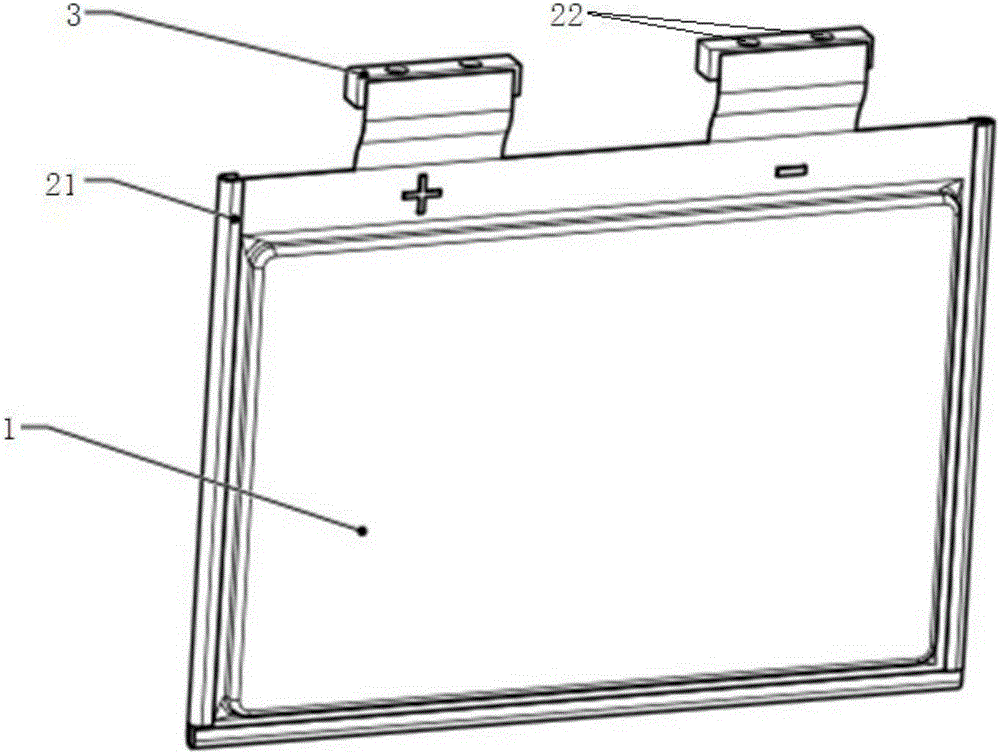

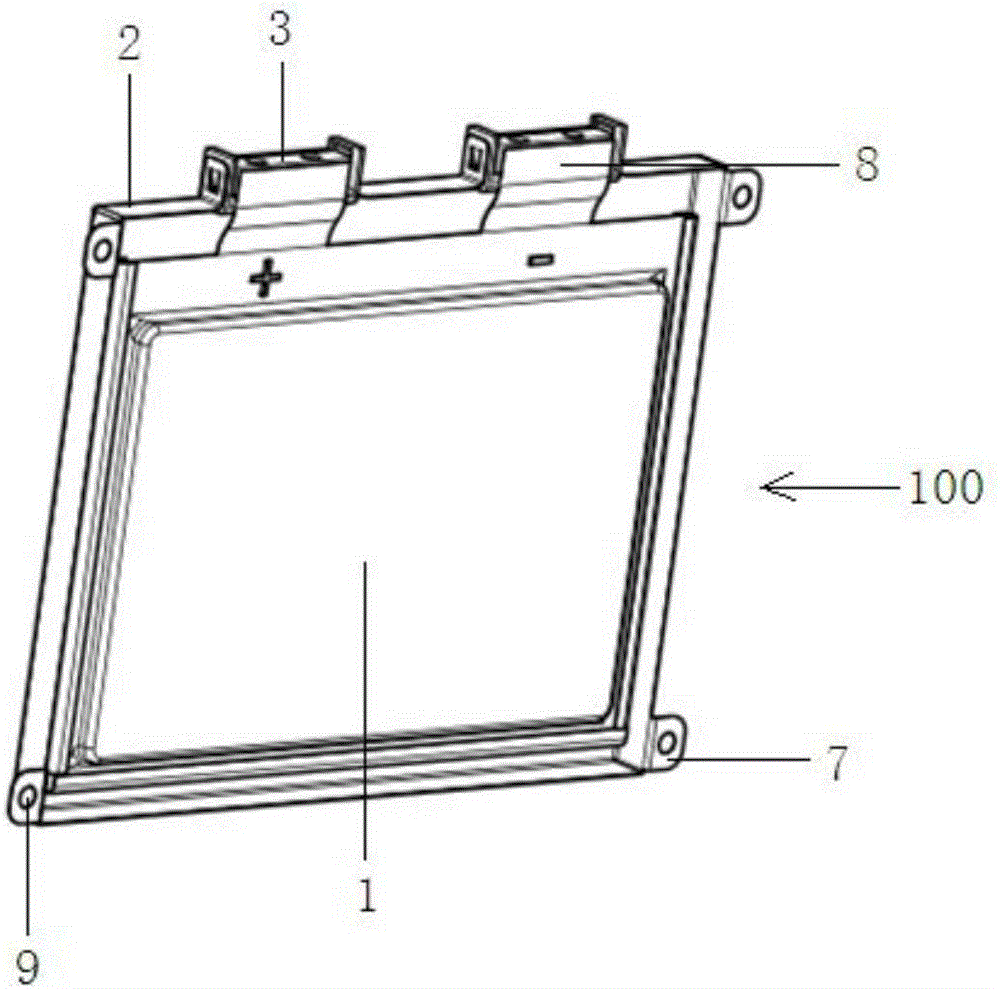

[0038] Please combine Figure 1 to Figure 8 As shown, a single battery cell 100 structure of a lithium battery of the present invention includes a battery cell 1 and a metal tray 2, wherein,

[0039] The battery cell 1 is a sheet-shaped battery cell, and the top of the battery cell 1 has two tabs 8, and each tab 8 is welded with a transfer metal block 3;

[0040] The metal tray 2 has an installation space 5 that matches the structure of the battery cell 1, and two insulating devices 4 are detachably clamped on the top, and each of the four corners of the metal tray 2 has a side ear 7, and the side ear 7 has a hole 9;

[0041] The transfer metal block 3 of the cell 1 is embedded in the insulating device 4 , the metal tray 2 covers the cell 1 , and there is a gap between the transfer metal block 3 and the insulating device 4 and can be installed floatingly relative to the insulating device 4 .

[0042] On the basis of the above, the present invention also has the following impl...

Embodiment 2

[0082] In this embodiment, the structure of the cell set and the module is basically the same as in Embodiment 1, the difference is that the metal tray 2 is changed to a plastic tray, and the insulating device 4 and the plastic tray are integrated into an integrated structure. The pressure plate 10 and the negative electrode side pressure plate 11 are made of metal, and the metal pressure plate and the copper connection bar are insulated. The middle pressure plate 12 is made of a plastic tray to improve the universality of parts. The metal pressure plate is designed as a radiator structure, which is conducive to heat dissipation and can also achieve For the same technical effect as that of the first embodiment, since the specific implementation is the same as that of the first embodiment, details are not repeated here.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap