A method for preparing new lead-acid batteries using active materials of waste lead-acid batteries

A lead-acid battery, active material technology, applied in lead-acid battery, lead-acid battery construction, secondary battery manufacturing and other directions, can solve problems such as simplifying waste lead-acid battery recycling process, and improve production efficiency , the effect of reducing the risk of contamination and simplifying the treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

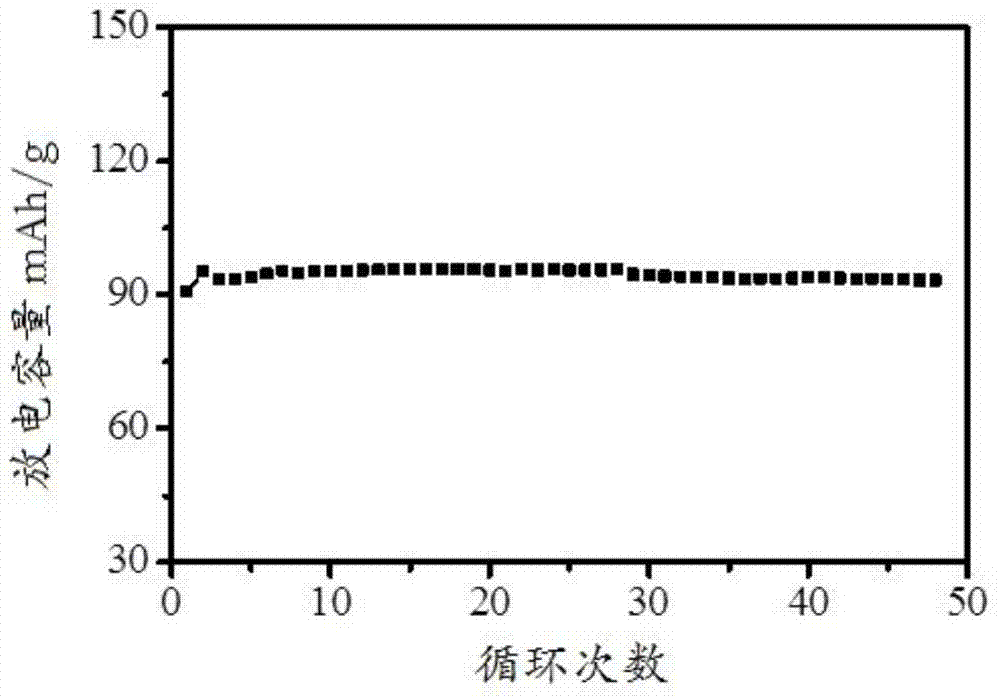

Examples

Embodiment 1

[0046] A kind of method utilizing the active material of waste lead-acid battery of the present invention to prepare new lead-acid battery comprises the steps:

[0047] (1) The waste lead-acid battery is cut from the upper part, and the positive electrode sheet and the negative electrode sheet, the electrolyte sulfuric acid, and the plastic casing are obtained by separation; the positive electrode sheet and the negative electrode sheet are respectively processed by water flow washing, ultrasonic wave or mechanical impact to obtain the positive electrode active material powder ( Hereinafter referred to as "positive electrode powder"), negative electrode active material powder (hereinafter referred to as "negative electrode powder"), positive electrode grid alloy, negative electrode grid alloy and waste separator;

[0048] (2) Put the positive electrode powder into a stirred reactor, and analyze the PbSO in the positive electrode powder obtained 4 content, according to PbSO 4 A...

Embodiment 2

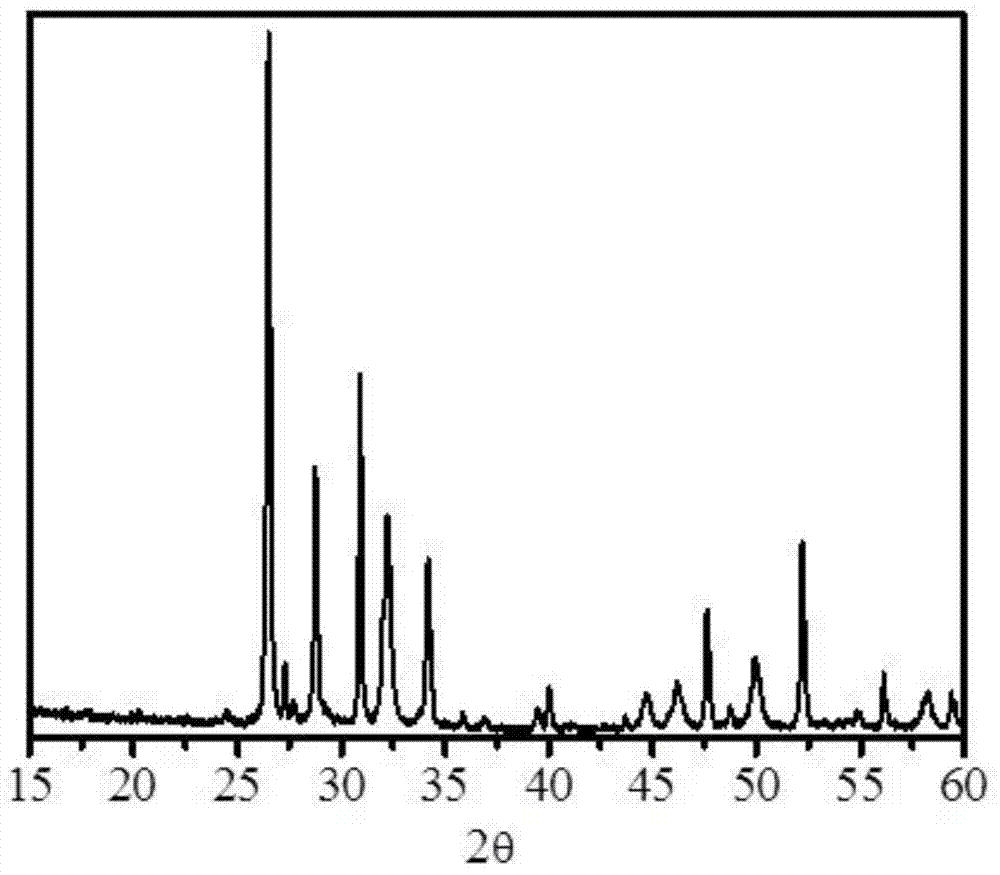

[0056] The chemical treatment process of positive electrode powder and negative electrode powder is as follows:

[0057] Positive electrode powder treatment: put the positive electrode powder into a stirred reactor, analyze and determine the PbSO in the positive electrode powder 4 The content of sodium carbonate added and PbSO in positive electrode powder 4 The molar ratio is 0.5:1 to partially desulfurize the positive electrode powder. Stir to react, the reaction temperature is 30°C, and the reaction time is 1h; the solid is obtained by filtration, and then washed to remove sodium sulfate; the obtained solid is calcined in an air atmosphere at 500°C for 1h to obtain a new positive electrode powder;

[0058] Negative electrode powder treatment: put the negative electrode powder into a stirred reactor, analyze and determine the PbSO in the negative electrode powder 4 content, according to PbSO 4 The content of excess 5% NaOH aqueous solution is added to completely desulfuriz...

Embodiment 3

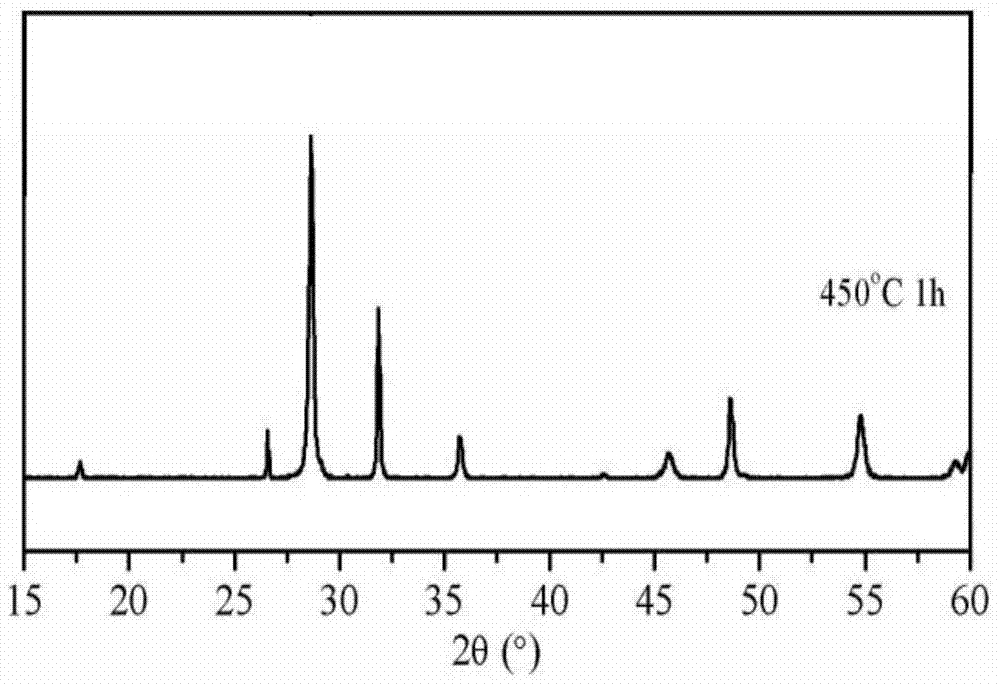

[0061] The chemical treatment process of positive electrode powder and negative electrode powder is as follows:

[0062] Positive electrode powder treatment: put the positive electrode powder into a stirred reactor, analyze and determine the PbSO in the positive electrode powder 4 content, according to PbSO 4 Add an excess of 5% KOH aqueous solution to completely desulfurize the positive electrode powder, and stir to make it react. The reaction temperature is 40°C, and the reaction time is 0.5h; the solid is obtained by filtration, and then washed to remove potassium sulfate; the obtained solid is calcined in an air atmosphere at 600°C for 0.5h to obtain a new positive electrode powder;

[0063] Negative electrode powder treatment: put the negative electrode powder into a stirred reactor, analyze and determine the PbSO in the negative electrode powder 4 content, the added potassium carbonate and PbSO in the negative electrode powder 4 The molar ratio is 0.9:1, so that the n...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap