An automatic cable cutting and stripping machine

A stripping machine and wire cutting technology, which is applied in the direction of dismantling/armoring cable equipment, etc., can solve the problems of cutting the core, reducing the wires in the joint, loosening, etc., achieving the effect of precise size and ensuring the conductive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

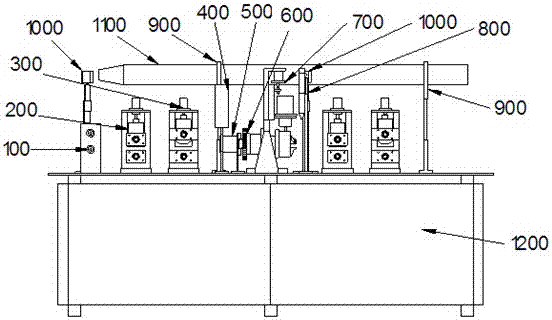

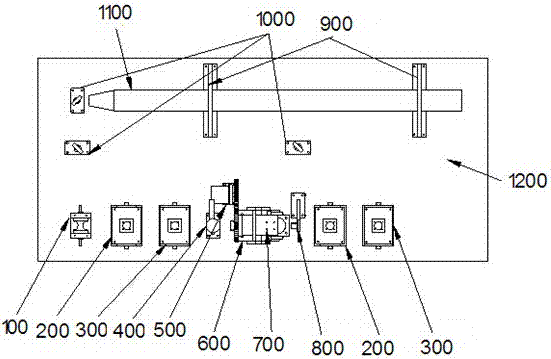

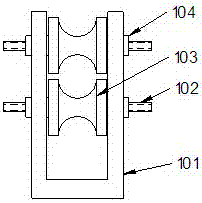

[0042] refer to figure 1 , figure 2 , this embodiment includes a guiding gantry 100, a measuring gantry 200, a wire routing gantry 300, a hydraulic thread cutting machine 400, a drive motor assembly 500, a rotating mechanism 600, a slide-rotating mechanism 700, a laser cutting head assembly 800, and a laser tube bracket 900 , mirror assembly 1000, laser tube 1100, wire cutting and peeling machine frame 1200, guiding gantry 100, measuring gantry 200, wire routing gantry 300, hydraulic thread cutting machine 400, drive motor assembly 500, rotating mechanism 600, slide-rotating mechanism 700, laser cutting head assembly 800, laser tube bracket 900, mirror assembly 1000 and laser tube 1100 are all installed on the wire cutting and peeling machine frame 1200; laser tube 1100 is horizontally fixed on the laser tube bracket 900, slide-rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com