Enhanced analysis for image-based serpentine belt wear evaluation

An image and image rotation technology, applied in image enhancement, image analysis, image data processing and other directions, can solve the problems of difficult quantification of wear detection, belt wear, low frequency of occurrence, etc., to achieve the effect of improving speed and accuracy and improving images

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] One desired utility of the embodiments described herein is directed to processing images of a tape, and more specifically, images of a portion of a tape, for use by a tape analysis module, application, or engine. However, one of ordinary skill in the art will recognize that besides belts, other measured objects may benefit from the teachings herein, including, but not limited to, gears, pulleys, idlers, shafts, bearings, blades, and supports.

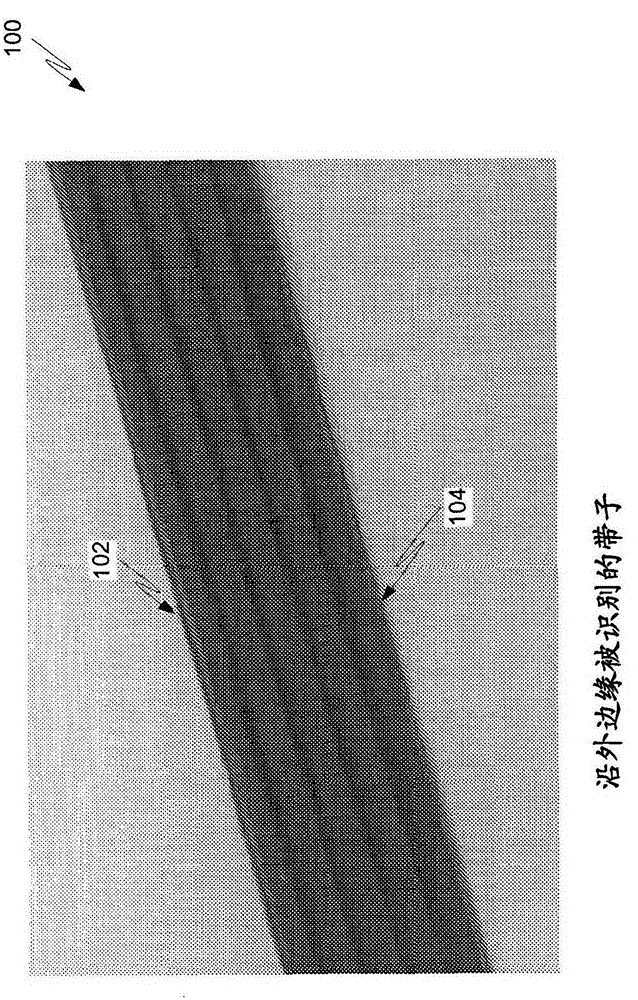

[0061] now refer to figure 1 , is the first sub-image 100 . Outer edges 102 and 104 are identified.

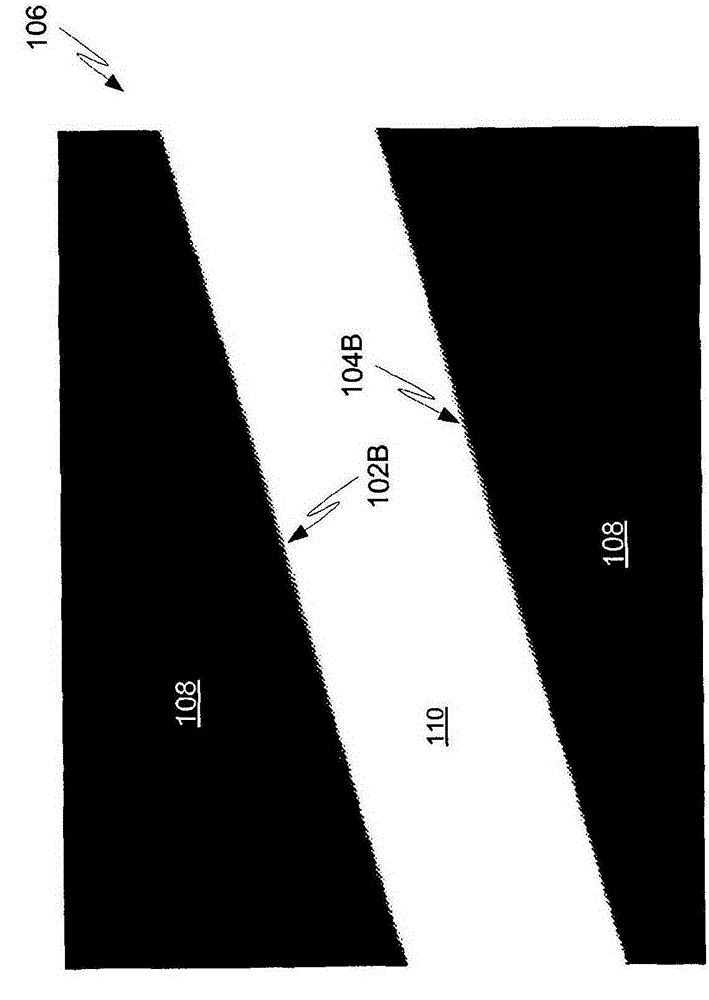

[0062] refer to Figure 1B , is the first band sub-image 100 after the adaptive thresholding algorithm. Figure 1B A second image 206 is shown with binary and inverted values. First and second tape edges 102B and 104B are illustrated and form the boundary between tape image 110 and background 108 .

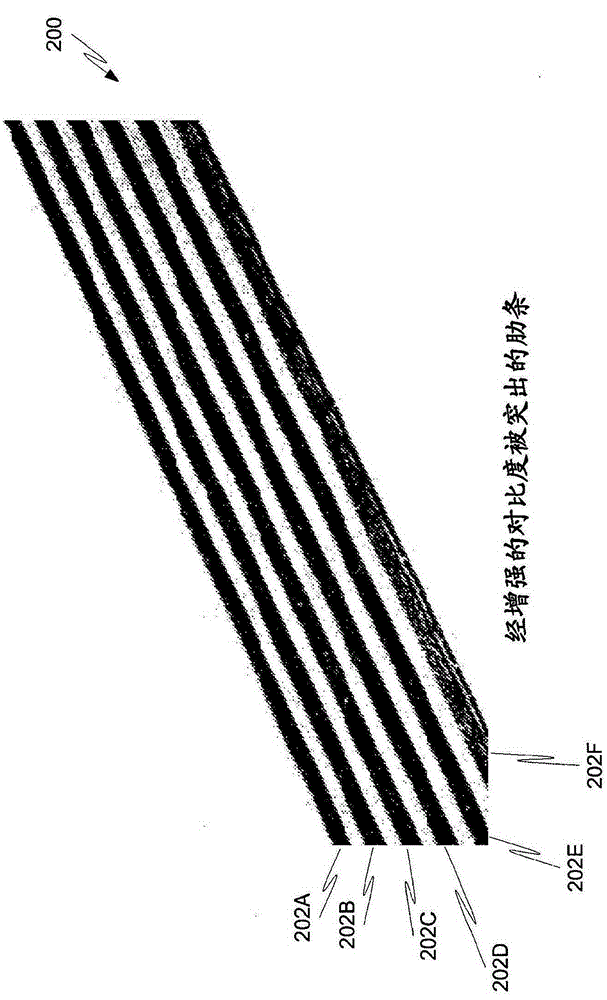

[0063] figure 2 is an enhanced contrast image 200 of the first strip image 100 . In the illustrated embodiment, 6 ribs (202...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com