Dried orange peel-Pu'er instant tea powder and preparation method thereof

A technology for instant tea powder and dried tangerine peel, which is applied in the field of tea products, can solve the problems of poor taste, long soaking time, and low attractiveness to teenagers, and achieves a technology that is beneficial to human health, ensures food safety, and maintains biological activity and nutritional components. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

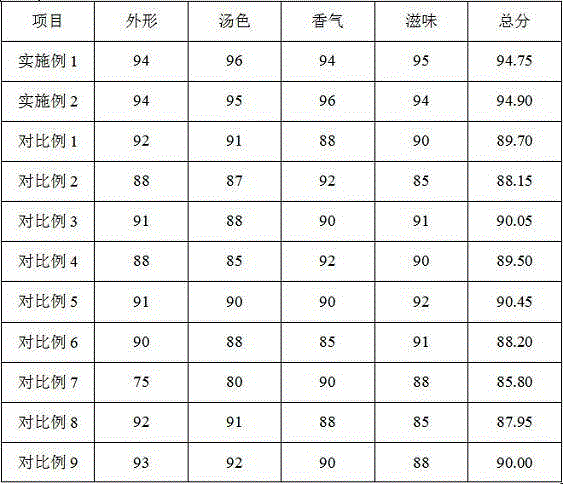

Examples

Embodiment 1

[0026] A kind of preparation method of tangerine peel Pu'er instant tea powder, comprises the steps:

[0027] S1: Weigh 15 parts of Xinhui tangerine peel and 85 parts of Yunnan cooked Pu'er tea in parts by weight. After the two are pulverized and mixed, water 32 times the weight of the mixture is added to the mixture, and the high-efficiency high-pressure differential extraction is carried out under the condition of a pressure of 20 MPa;

[0028] S2: The extract is centrifuged at a speed of 5500rpm, and impurities are filtered through a microporous membrane with a pore size of 3.0μm at 0.1Mpa;

[0029] S3: The extract after microfiltration was concentrated by reverse osmosis using RO membrane at 20°C until the soluble solids content was 10%;

[0030] S4: Add maltodextrin with a soluble solid content of 1:1 to the concentrated solution as a drying auxiliary material, spray drying with an inlet air temperature of 160°C, an outlet air temperature of 120°C, and an inlet air pressu...

Embodiment 2

[0033] A kind of preparation method of tangerine peel Pu'er instant tea powder, comprises the steps:

[0034] S1: Weigh 15 parts of Xinhui tangerine peel and 85 parts of Yunnan cooked Pu'er tea in parts by weight. After the two are pulverized and mixed, water 32 times the weight of the mixture is added to the mixture, and the high-efficiency high-pressure differential extraction is carried out under the condition of a pressure of 40Mpa;

[0035] S2: The extract is centrifuged at a speed of 5500rpm, and impurities are filtered through a microporous membrane with a pore size of 10.0μm at 0.2Mpa;

[0036] S3: The extract after microfiltration was concentrated by reverse osmosis using RO membrane at 30°C until the soluble solids content was 15%;

[0037] S4: Add maltodextrin with a soluble solid content of 1:1.5 to the concentrated solution as a drying auxiliary material, spray drying with an inlet air temperature of 180°C, an outlet air temperature of 150°C, and an inlet air pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com