Grouping processing method for tobacco stems based on color discrimination

A processing method and tobacco stem technology are applied in the field of tobacco stem grouping processing based on color discrimination, which can solve the problems of affecting the quality of cigarette products, reducing the filling value of cut stems, affecting the structure of cut stems, etc., so as to improve the quality of cut stems and improve the quality of cut stems. Silk structure, the effect of improving sensory quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

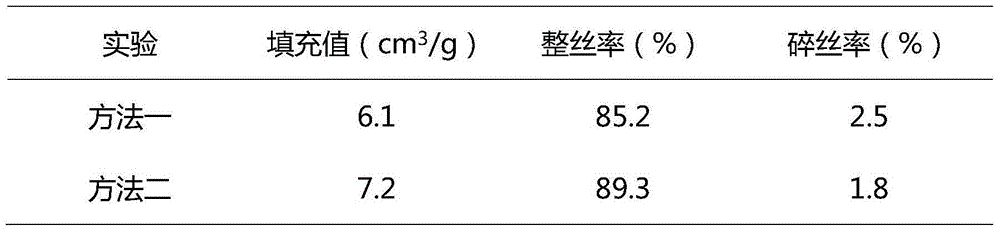

[0028] Example 1: The influence of the grouping processing method of tobacco stems based on color discrimination on the physical quality of cut stems

[0029] Sample: 6000kg of Yunnan tobacco stems aged for 2 years.

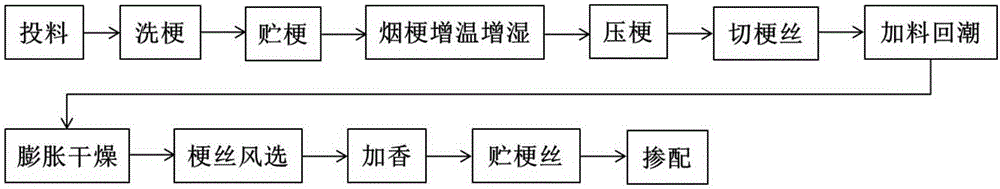

[0030] Method one: get the above-mentioned tobacco stem of 3000kg according to the technological process of prior art tobacco stem processing method (such as figure 1 Steps as shown) for processing, in which the tobacco stem is heated and humidified and the discharge temperature is 65°C, the stem pressing gap is 1.1mm, the thickness of the cut stem is 0.12±0.02, and the air temperature of the cut stem expansion and drying process is 195°C.

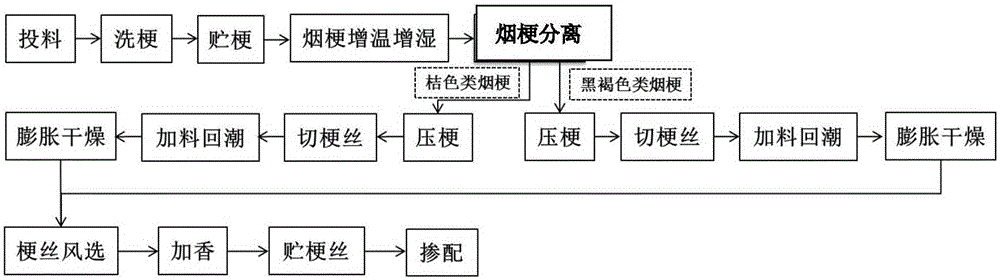

[0031] Method two: get 3000kg above-mentioned tobacco stem according to the technological process of the present invention based on color discrimination tobacco stem grouping processing method (such as figure 2 Steps shown) for processing, wherein the tobacco stems are heated and humidified and the discharge temperature is ...

Embodiment 2

[0036] Example 2: The influence of the tobacco stem grouping processing method based on color discrimination on the processing loss rate

[0037] The tobacco stems were processed according to the method of Example 1, the utilization rate of the tobacco stems was calculated according to the input-output method, and the weight of the prepared shredded stems was weighed before flavoring. The processing losses of the two processing methods are shown in Table 2:

[0038] Table 2 Comparison of processing losses of two tobacco stem processing methods

[0039]

[0040] Note: The stated weights are standard weights converted into 12% moisture content.

[0041] As can be seen from Table 2, the yield of cut stems processed by the prior art is 86.7%, and the loss rate is 13.3%; the yield of cut stems obtained after grouping and processing of tobacco stems based on color discrimination is 92.5%, The attrition rate was 7.5%. It shows that dividing tobacco stems into orange and dark br...

Embodiment 3

[0042] Example 3: Effects of color discrimination-based grouping and processing of tobacco stems on the sensory quality of cut stems

[0043] Take each 500 g of shredded tobacco samples before air selection of cut stems by two processing methods in Example 1, and 50 cigarettes of artificially rolled shredded stems samples, and balance in a constant temperature and humidity chamber with a relative humidity of 65% and a temperature of 22° C. for 48 hours. , balance the moisture content of cigarettes to 12%, and set aside.

[0044] The evaluation group is composed of 7 qualified judges, and the nine-point scoring method is used to evaluate the samples respectively. The results are shown in Table 3:

[0045] Table 3 Comparison of sensory quality of shredded stems produced by two tobacco stem processing methods

[0046]

[0047] It can be seen from Table 3 that there are differences in the aroma and smoke characteristics between the shredded stems obtained after grouping and pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com