A kind of refreshing sunscreen or moisturizer and preparation method thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

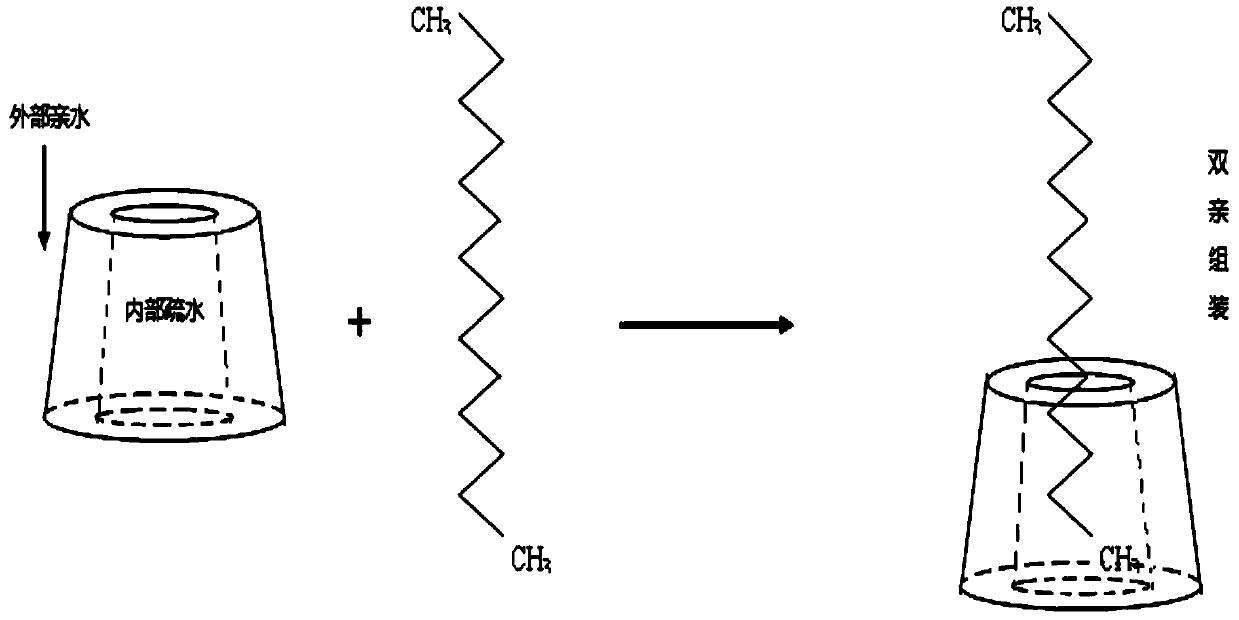

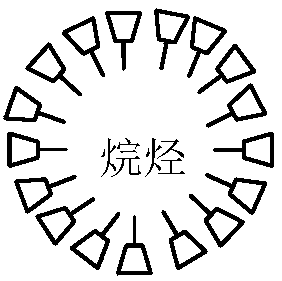

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Preparation of heat storage components

[0031] In a 500ml round bottom flask equipped with a stirring and heating device, add 30g of β-cyclodextrin, 60g of 35# paraffin, and 210g of deionized water, slowly raise the temperature to 50°C while stirring, and continue stirring for 3 hours until a uniform suspension is formed. solution to prepare the heat storage complex component, marked as HS-1.

[0032] (2) Preparation of oil-in-water sunscreen

[0033] Add HS-1 into the oil-in-water sunscreen formula to prepare a cool sunscreen.

[0034] Three groups of oil-in-water sunscreens were prepared, and the formula composition is shown in Table 1.

[0035] Table 1 Three groups of formulations of oil-in-water sunscreen

[0036]

[0037] The three groups of sunscreens prepared in Table 1 above were evenly coated on a glass plate, and the glass plate was placed on a constant temperature hot stage substrate at 50°C, and the change of coating temperature was measured. The ...

Embodiment 2

[0043] (1) Preparation of heat storage components

[0044] In a 500ml round bottom flask equipped with a stirring and heating device, add 30g of α-cyclodextrin, 60g of ethyl stearate, and 210g of deionized water, slowly raise the temperature to 50°C while stirring, and continue stirring for 3h until a uniform Suspension of the heat storage compound was prepared, and the price was HS-2.

[0045] (2) Preparation of water-in-oil sunscreen

[0046] Add HS-2 into the formula of water-in-oil sunscreen to prepare a cool sunscreen.

[0047] Three groups of water-in-oil sunscreens were prepared, and the formula composition is shown in Table 3.

[0048] Table 3 Three groups of formulations of water-in-oil sunscreen

[0049]

[0050] The three groups of sunscreens prepared in Table 3 above were evenly coated on a glass plate, and the glass plate was placed on a constant temperature hot stage substrate at 50°C, and the change of coating temperature was measured. The results are shown ...

Embodiment 3

[0056] (1) Preparation of heat storage components

[0057] In a 500ml round bottom flask equipped with a stirring and heating device, add 30g of γ-cyclodextrin, 30g of dodecyl alcohol, 30g of myristyl alcohol, and 210g of deionized water, slowly raise the temperature to 50°C while stirring, and continue stirring for 3h. Until a uniform suspension was formed, a heat storage complex component was prepared, labeled HS-3.

[0058] (2) Formula of cooling moisturizer

[0059] HS-3 was added to the moisturizer formula to prepare two groups of cool moisturizer.

[0060] Table 5 Formulation of Cooling Moisturizer

[0061]

[0062] The moisturizer prepared in the above Table 5 was evenly coated on a glass plate, and the glass plate was placed on a constant temperature hot-stage substrate at 50°C, and the change of the coating temperature was measured. The results are shown in Table 6.

[0063] Table 6. Temperature rise after moisturizer plus HS-3

[0064]

[0065] It can be se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com