Self-rotating type insulator cleaning device

A technology for cleaning devices and insulators, applied in cleaning methods and appliances, cleaning methods using tools, chemical instruments and methods, etc., can solve the problems of power transmission safety impact, insulator insulation performance impact, time-consuming and labor-intensive efficiency, etc., to improve battery life , Reduce labor intensity, reduce the effect of replacement or charging times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

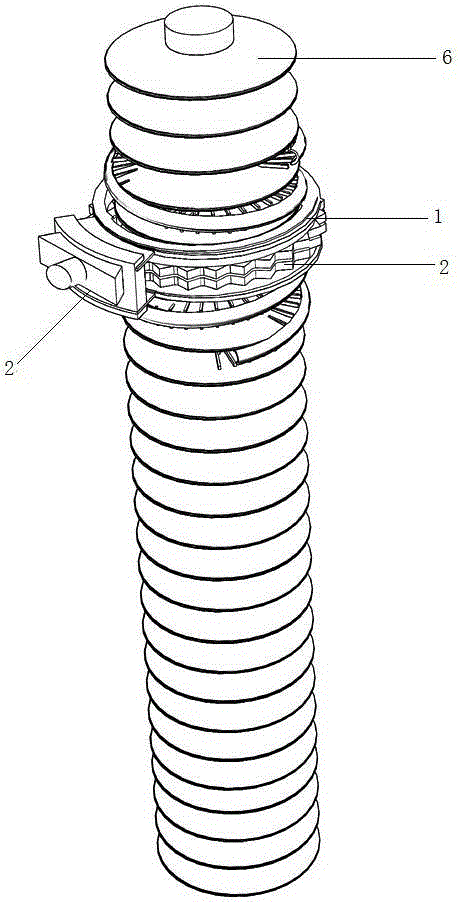

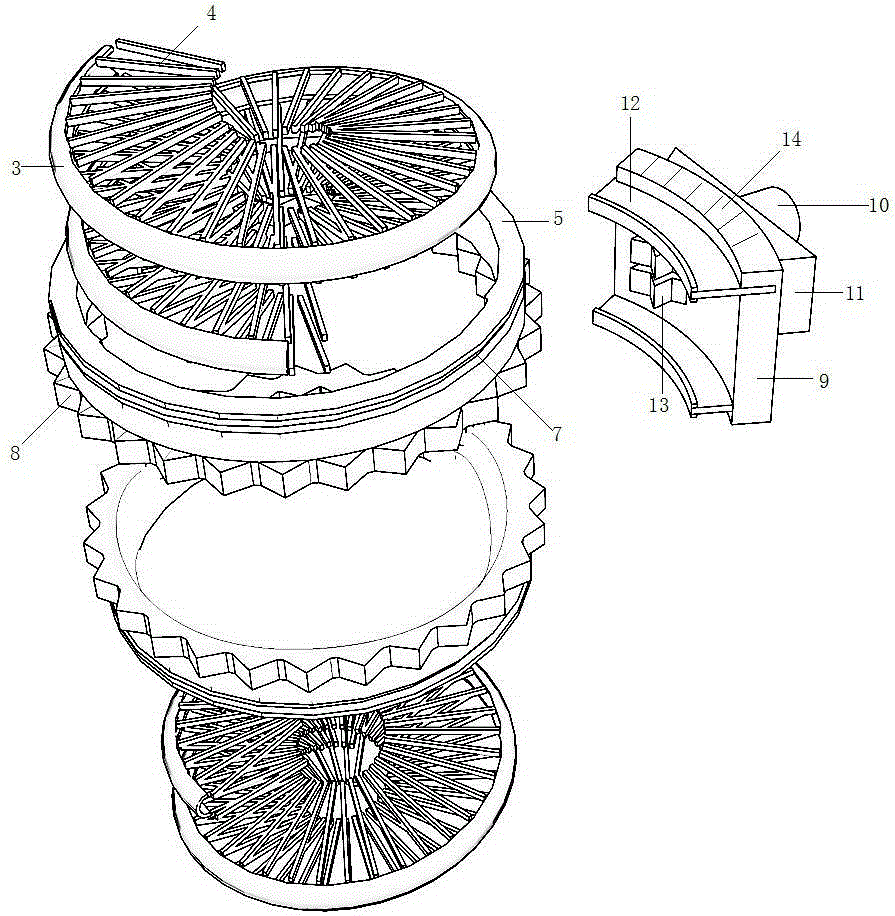

[0018] Such as Figure 1-2 As shown, the spin-type insulator cleaning device includes an insulator body 6, includes two spiral cleaning units 1 arranged symmetrically in the vertical direction, and a drive unit 2 that connects and drives the two spiral cleaning units 1; the spiral cleaning unit 1 includes a spiral Shaped guide half-pipe body 3, brush bundle 4 that is uniformly distributed on the spiral guide half-pipe body 3 radially inward, surrounds the driving ring 5 fixed on the outside of the spiral guide half-pipe body 3; The section of the semi-pipe body 3 is semi-circular and coincides with the shed edge of the insulator body 6; the outer surface of the driving ring 5 is provided with a guide groove 7 and an external gear 8 in the vertical direction; the driving unit 2 includes a base 9, The driving motor 5 installed on the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com