High current fast charger for electric bus

A fast charging and electric bus technology, applied in electric vehicles, electric traction, vehicle energy storage, etc., can solve the problems of poor insulation and unusability in rainy days, and solve the problem of messy distribution of devices, convenient maintenance and repair, and messy distribution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

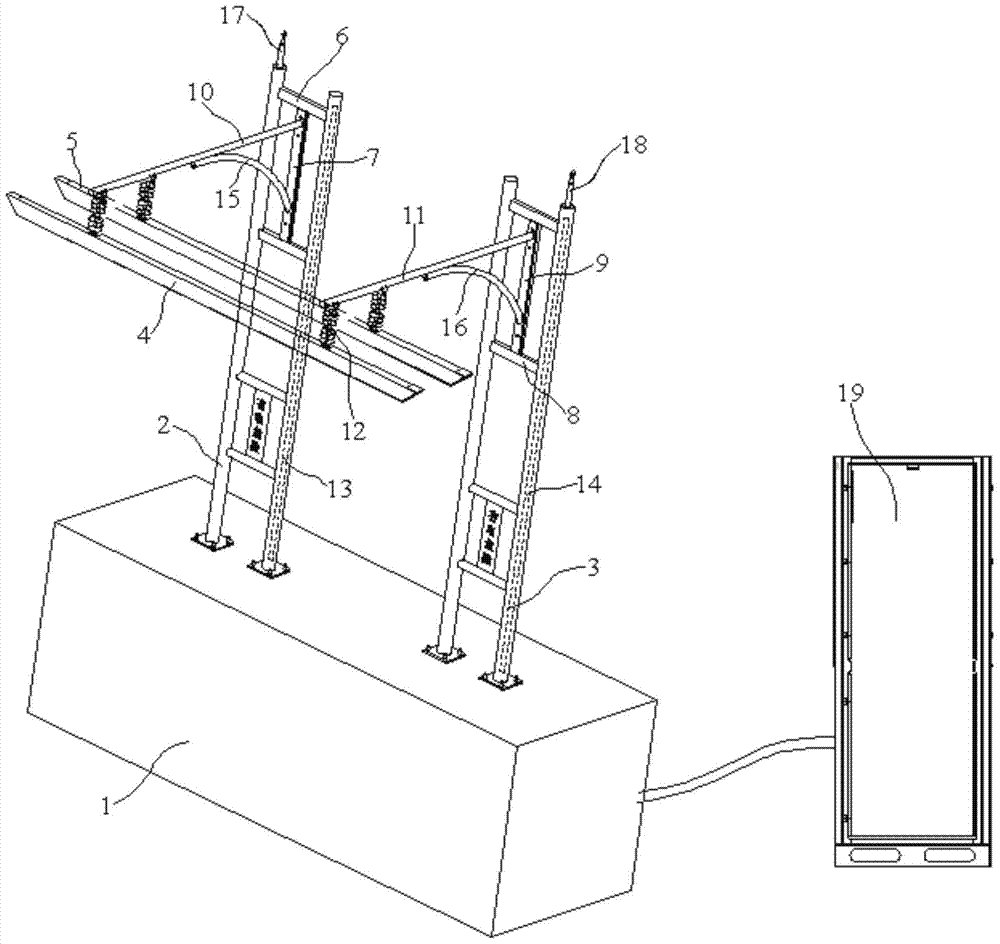

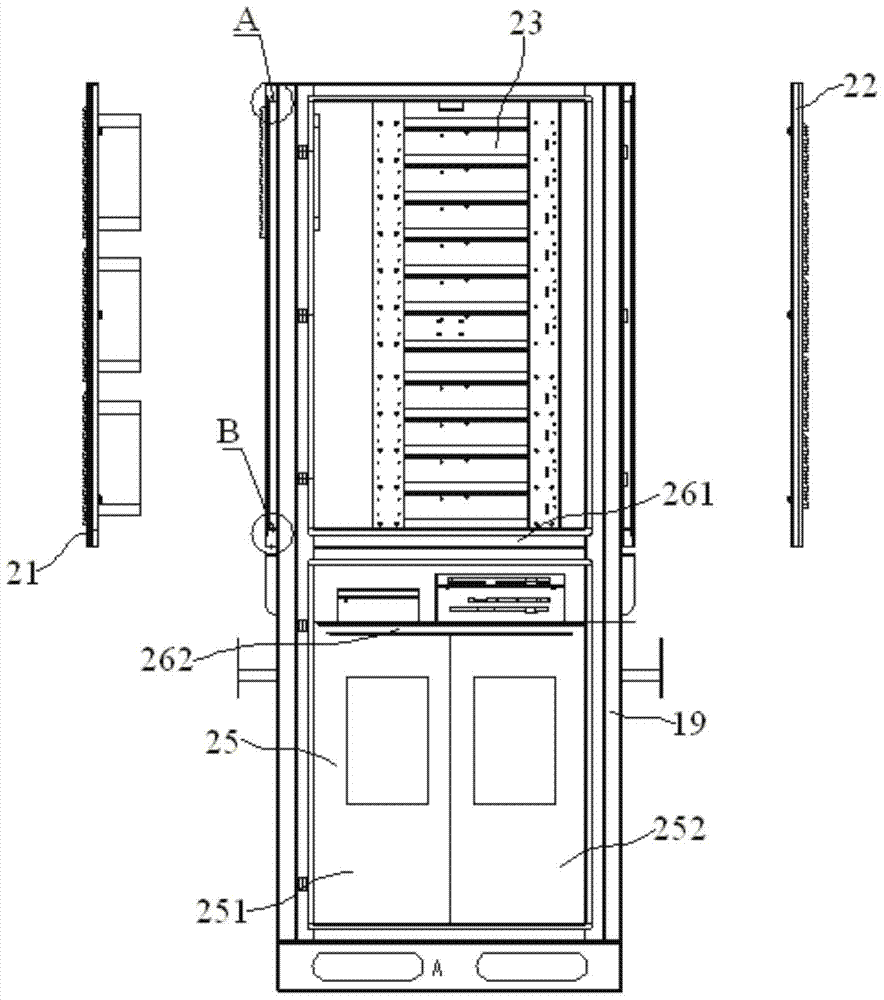

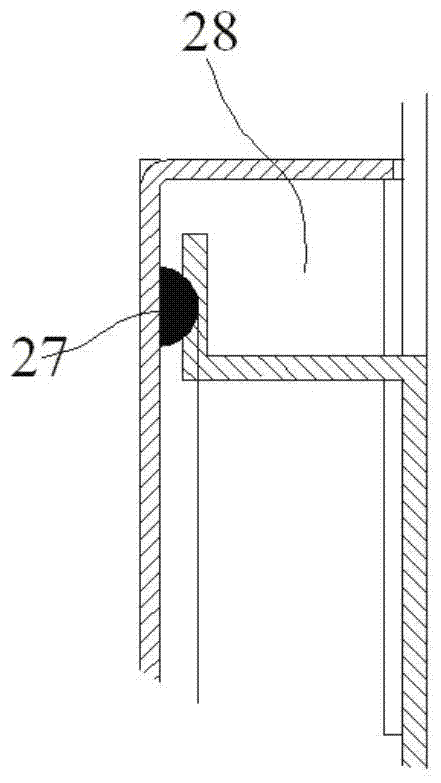

[0032] Embodiment 1: A high-current fast charger applied to electric buses, including a charging power cabinet, a foundation 1, 2 positive pole fixing tubes 2, 2 negative pole fixing tubes 3, a positive pole busbar 4 and a negative pole busbar 5, The charging power cabinet is used to convert industrial three-phase 380-volt alternating current into direct current matching electric vehicles. The charging power cabinet further includes a cabinet body 19, a front door panel 20, a left door panel 21 and a right door panel 22. The cabinet body 19 is provided with a charging module area 23, a central control area 24, and an input and output terminal electrical area 25 in sequence from top to bottom. The charging module area 23 is used to convert industrial alternating current into direct current. The boards 261, 262 are isolated from the charging module area 23 and the electrical area of the input and output terminals 25;

[0033]The left door panel 21, the right door panel 22 and ...

Embodiment 2

[0046] Embodiment 2: A high-current fast charger applied to electric buses, including a charging power cabinet, a foundation 1, 2 positive pole fixing tubes 2, 2 negative pole fixing tubes 3, a positive pole busbar 4 and a negative pole busbar 5, The charging power cabinet is used to convert industrial three-phase 380-volt alternating current into direct current matching electric vehicles. The charging power cabinet further includes a cabinet body 19, a front door panel 20, a left door panel 21 and a right door panel 22. The cabinet body 19 is provided with a charging module area 23, a central control area 24, and an input and output terminal electrical area 25 in sequence from top to bottom. The charging module area 23 is used to convert industrial alternating current into direct current. The boards 261, 262 are isolated from the charging module area 23 and the electrical area of the input and output terminals 25;

[0047] The left door panel 21, the right door panel 22 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com