Top cover and side wall welding assembly structure

A technology of assembly structure and top cover, which is applied in the connection, transportation and packaging between the upper structure and the sub-assembly of the upper structure, and can solve the problems of large solder joint spacing, difficult welding operation, and weak solder joints, etc. To achieve the effect of improving performance and modality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

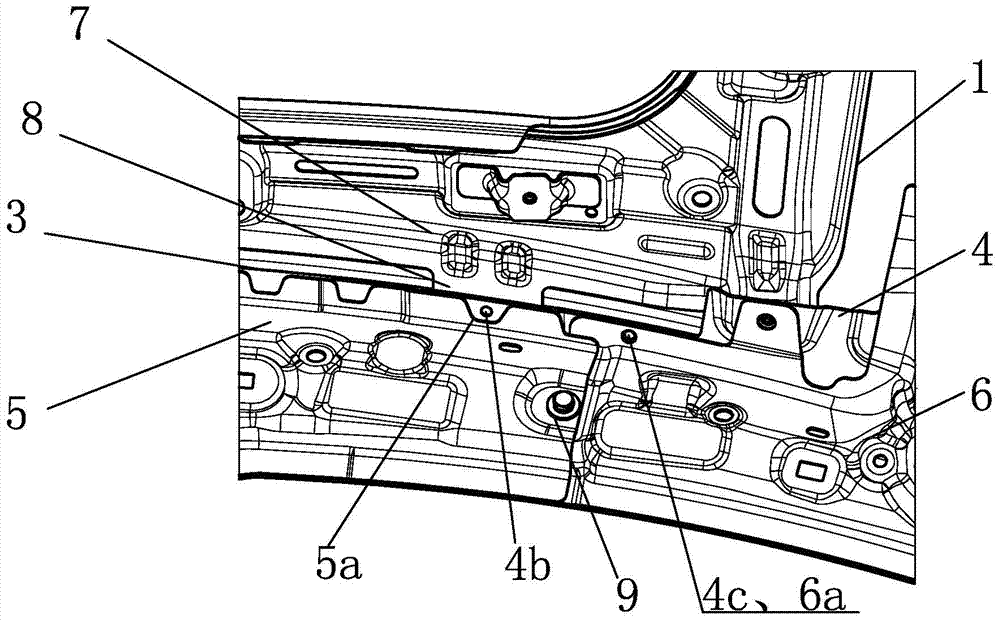

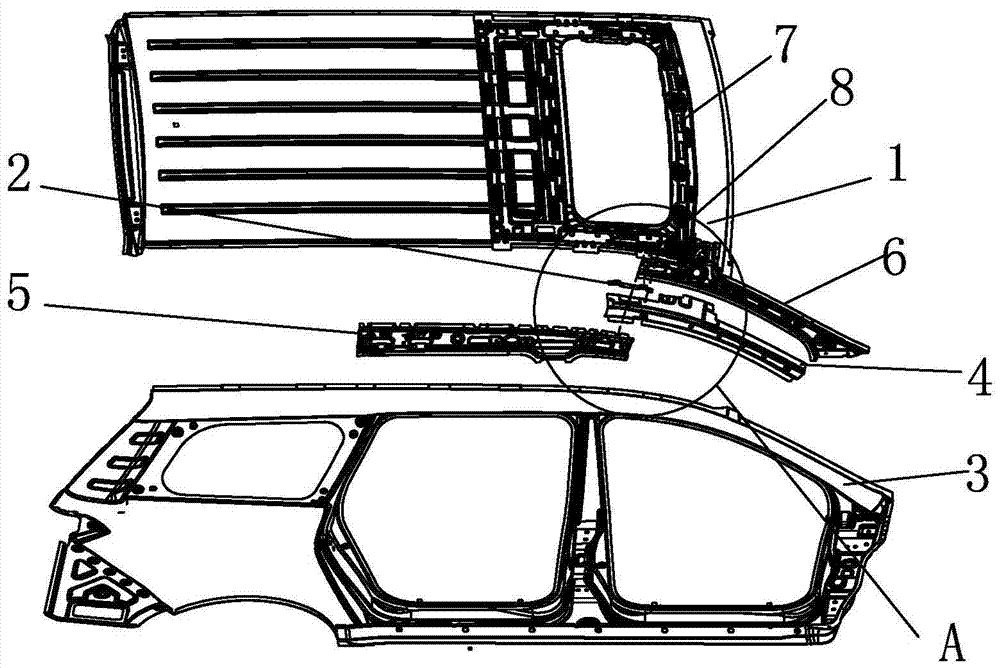

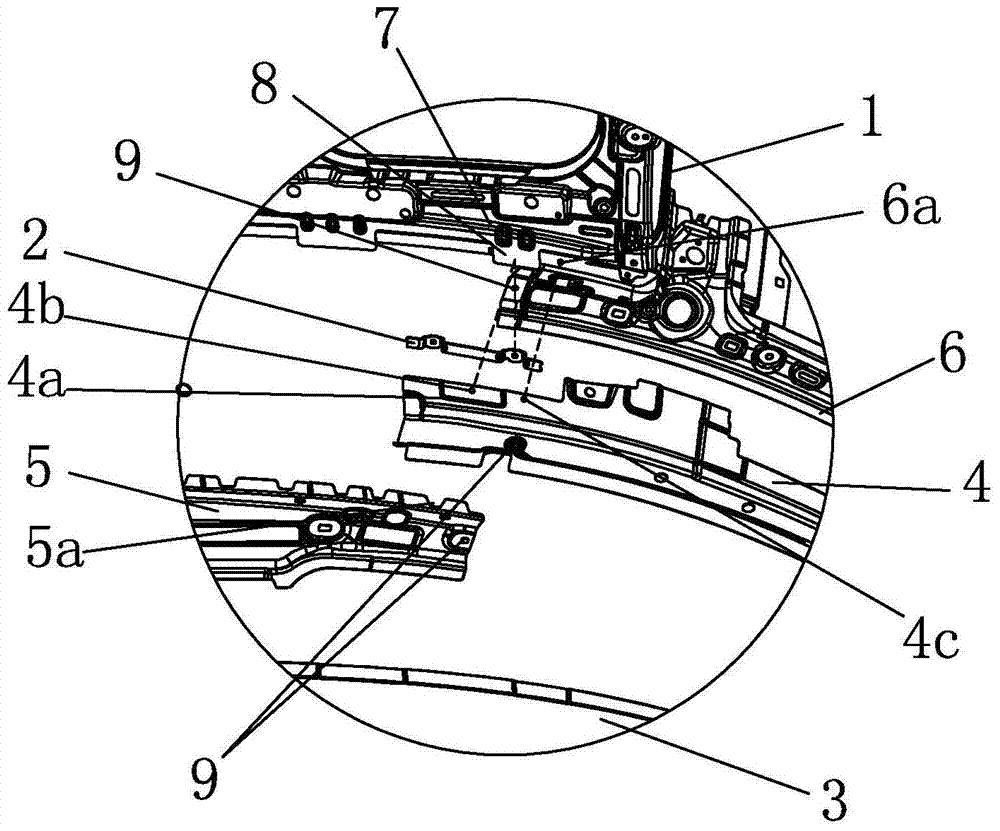

[0017] Such as figure 1 , 2 Shown in and 3: a top cover and side wall welding assembly structure, which consists of a top cover 1, a luggage mounting bracket 2, a side wall outer panel 3, a reinforcement plate 4 on the front pillar, an inner side beam 5 on the center pillar inner panel, and a front pillar The upper inner plate 6 consists of six parts, such as Figure 4 with 5 As shown, the connecting parts of the luggage installation bracket 2, the top cover 1, the side wall outer panel 3, and the reinforcement plate 4 on the front pillar are arranged in sequence from the inside to the outside; are all located on the outer side of the reinforcing plate 4 on the front column,

[0018] Such as figure 1 , 2 As shown in and 3, the top cover 1 is provided with a sunroof reinforcement ring 7, and the edge of the reinforcement ring 7 is provided with a welding block 8, and the welding block 8 is located at the connection part of the top cover 1 and the side wall outer panel 3 B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com