Integrated packaging box making and filling equipment and its box making and filling process

A technology for filling equipment and packaging boxes, which is applied in the field of integrated packaging box-making and filling equipment and its box-making and filling process, which can solve the problem that the efficiency of the box-making unit and the filling device cannot be synchronized, and the box-making cannot be completed at one time And the problems of poor forming effect of filling and sealing packaging products, to achieve the effect of eliminating turnover transportation links, improving quality and food safety, and cost-effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

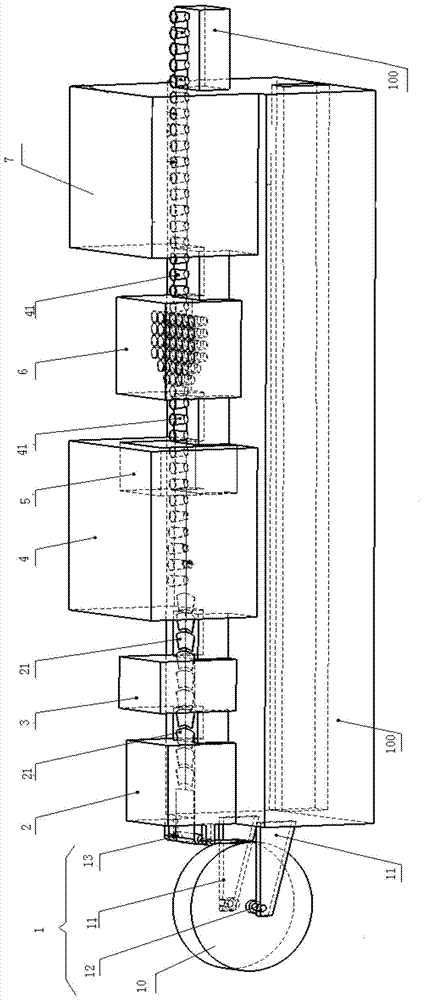

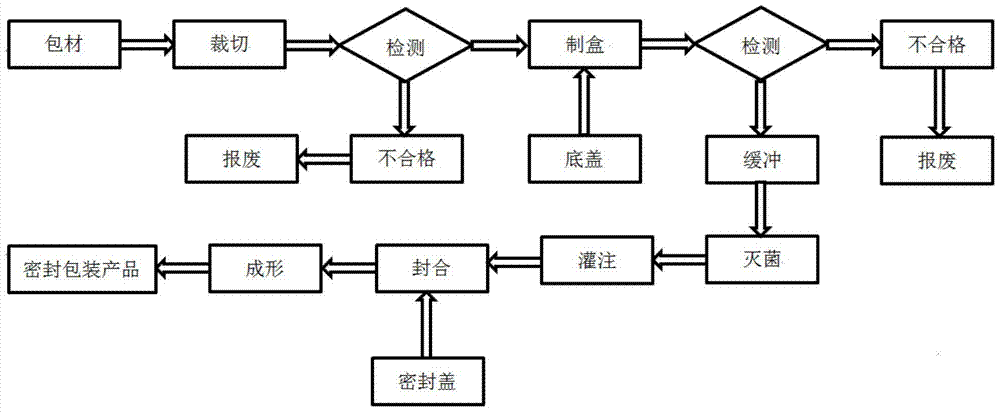

[0032] Such as figure 1 As shown, an integrated packaging box making and filling equipment is disclosed in this embodiment, which includes a frame 100. According to the sequence of the process flow, the above frame 100 is sequentially provided with: packaging material feeding unit 1 , cutting unit 2, detection waste discharge device one 3, box making unit 4, detection waste discharge device two 5, buffer unit 6 and filling molding unit 7, the above-mentioned packaging material feeding unit 1 is used to transport the packaging material 10 to 2 in the above-mentioned cutting unit, the above-mentioned cutting unit 2 cuts the packaging material into sheet-shaped blanks, and the above-mentioned detection waste discharge device-3 detects the sheet-shaped blanks 21 coming out of the above-mentioned cutting unit 2 and rejects the waste blanks, The above-mentioned box-making unit 4 rolls the above-mentioned sheet blank 21 into a packaging box blank 41, and the above-mentioned detection...

Embodiment 2

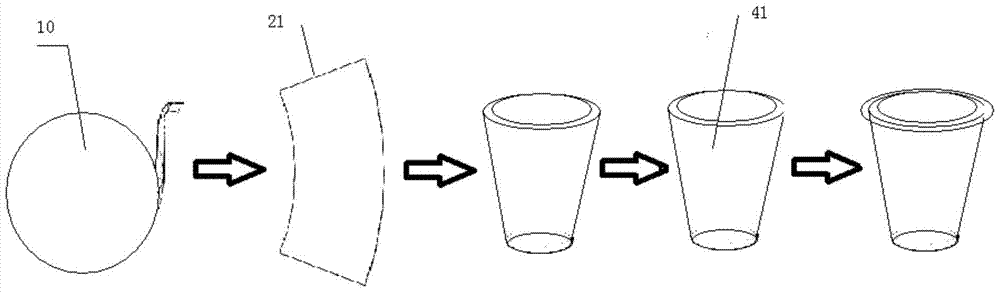

[0052] The structure of the integrated packaging box making and filling equipment in embodiment 2 is consistent with the structure in embodiment 1, and the box making process of the packaging box in embodiment 2 is as follows Figure 4 As shown, in this embodiment, the packaging box is a rectangular pointed top packaging box, and its production process is: the sealed packaged product is a conical cup-shaped sealed packaging box, and its production process is: the packaging material is cut into pieces by the cutting unit 2 Shape blanks and sheet blanks are passed through the first inspection of the waste discharge device, and then made into packaging box blanks by the box making unit; the packaging box blanks pass the second inspection of the waste discharge device, and are buffered by the buffer unit before entering the sterilization device for sterilization , and then the product is poured by the filling device, and finally the top of the filled packaging blank is sealed and f...

Embodiment 3

[0054] The structure of the integrated packaging box making and filling equipment in embodiment 3 is consistent with the structure in embodiment 1, and the box making process of the packaging box in embodiment 3 is as follows: Figure 5 As shown, in this embodiment, the packaging box is a rectangular pointed top packaging box, and its production process is: the sealed packaged product is a conical cup-shaped sealed packaging box, and its production process is: the packaging material is cut into pieces by the cutting unit 2 Shape blanks and sheet blanks are passed through the first inspection of the waste discharge device, and then made into packaging box blanks by the box making unit; the packaging box blanks pass the second inspection of the waste discharge device, and are buffered by the buffer unit before entering the sterilization device for sterilization , and then the product is poured by the filling device, and finally the sealing device is used to seal the filling port ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com