Steel support for overlapped tunnels

A steel support and tunnel technology, applied in tunnels, tunnel linings, shaft equipment, etc., can solve problems such as stress concentration of support segments, insufficient protection of down tunnels, and difficult manufacturing, and meet the requirements for enhanced protection and mechanical processing workers Low, fast dismantling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to better understand the technical solution of the present invention, the present invention will be further described below through examples and accompanying drawings.

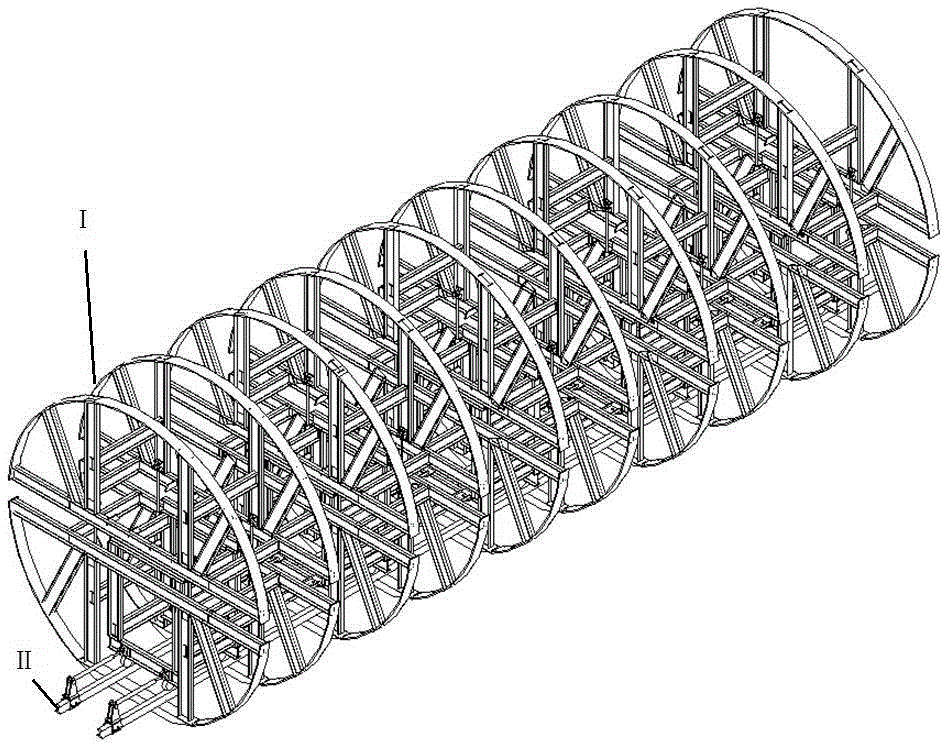

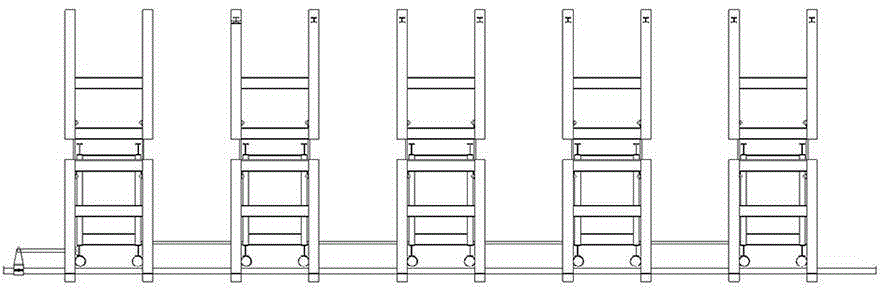

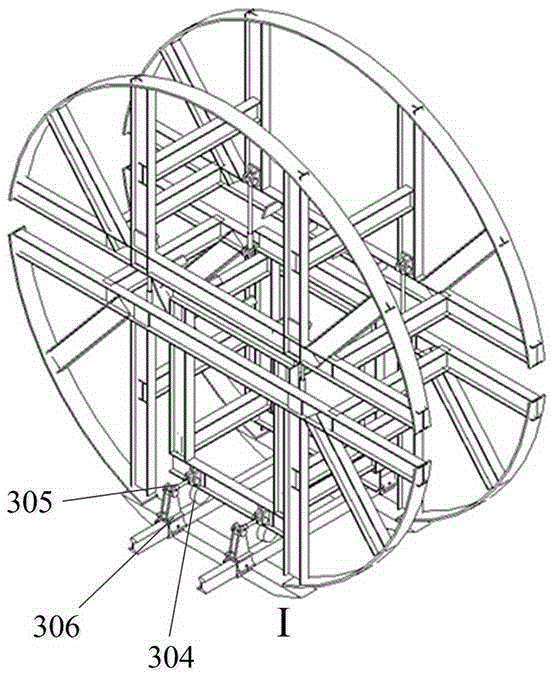

[0037] Such as figure 1 , 2 As shown in , 3, an overlapping tunnel steel support is characterized in that it is mainly composed of multiple identical support systems I and rails II (the number of the support systems I depends on the specific situation, five is the best), Multiple support systems I (vertical) are placed side by side on the track II; the support system I is a circular structure (that is, a structure that matches the overlapping tunnel segments), and a single rim 304 (that is, a single rim wheels), the single rim 304 falls on the track II; the adjacent supporting systems I are fixedly connected by several connecting pieces (the connecting pieces are preferably channel steel); the lower part of the last supporting system I is set There is a track lock 306, the track lock 306 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com