Electromagnetic metering ball valve

A ball valve, electromagnetic technology, applied in the valve details, valve device, valve operation/release device and other directions, to achieve the effect of high measurement accuracy, cost reduction, and accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

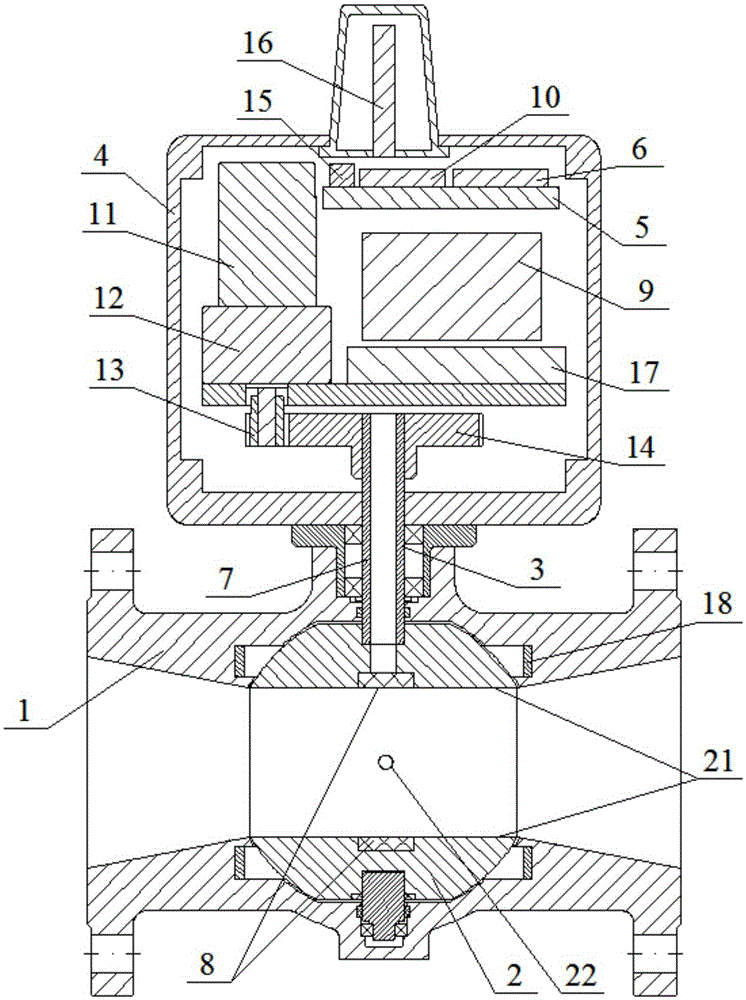

[0029] Such as figure 1 The electromagnetic metering ball valve shown includes a valve body 1, a ball core 2 inside the valve body 1, a valve stem 3 that drives the ball core 2 to rotate, and an electric control box 4 outside the valve body 1; Fluid through hole 21 is arranged, and the paired electrode 22 that is arranged with electromagnetic induction coil 8 and is arranged in the magnetic field scope of electromagnetic induction coil 8 oppositely is provided with in fluid through hole 21, and fluid flows through electromagnetic induction coil 8 and electrode 22 and An induced current is generated on the electrode 22; a circuit board 5 is arranged in the electric control box 4; the electromagnetic induction coil 8 is electrically connected with the circuit board 5 through a wire to form a closed loop; the electrode 22 is connected with the circuit board 5 through a wire; A processing module 6 for obtaining real-time flow information of the fluid by processing the induced curr...

Embodiment 2

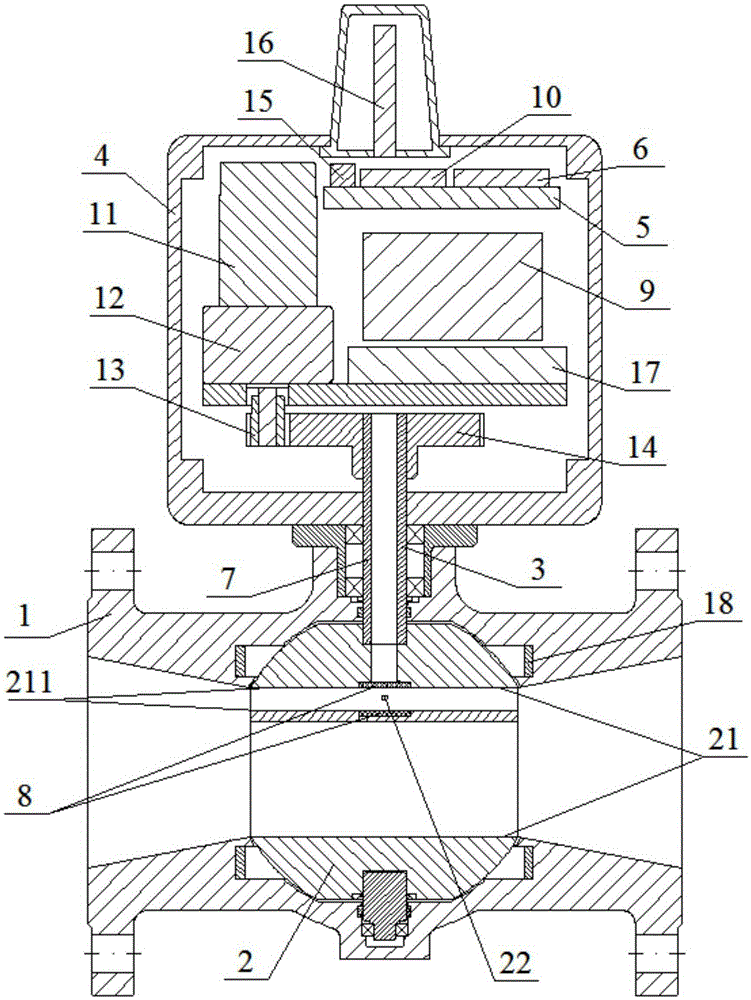

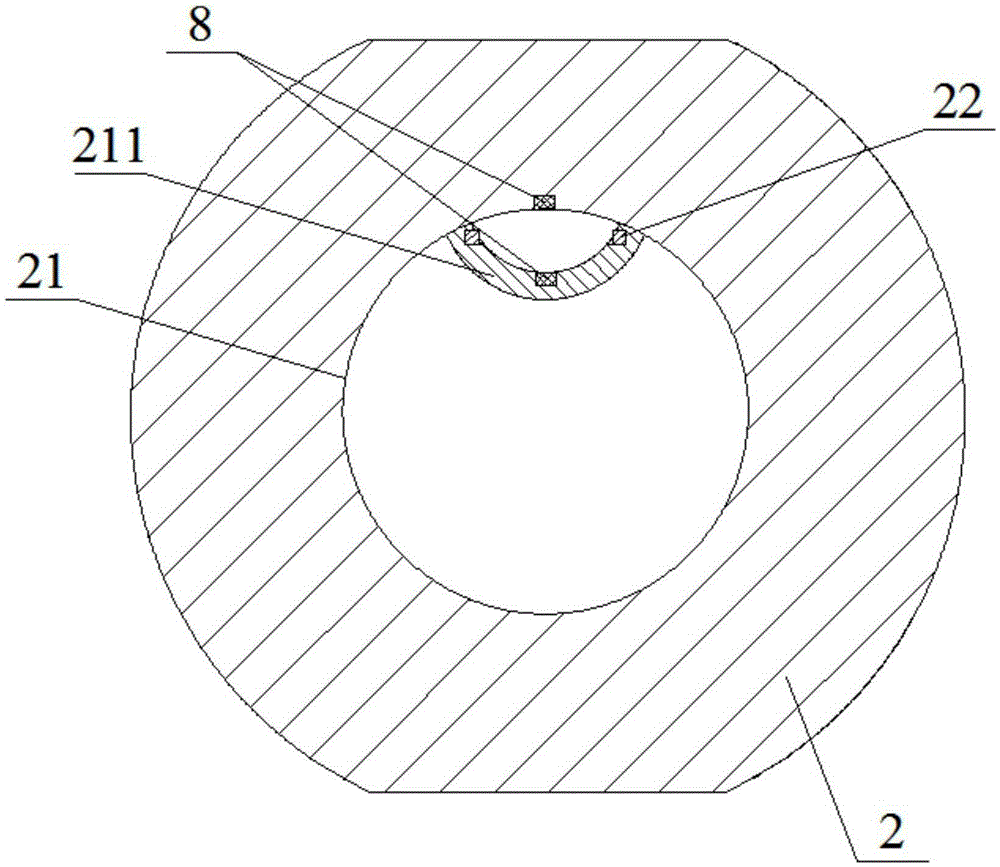

[0035] Such as figure 2 , 3 As shown, the structure of the electromagnetic metering ball valve in the present invention is basically the same as that of Embodiment 1, the difference is that a hollow flow measuring tube 211 is arranged on the inner wall of the fluid through hole 21, and the arrangement direction of the flow measuring tube 211 is the same as that of the fluid through hole 21. The directions are consistent; the electromagnetic induction coil 8 is arranged on the inner wall of the flow tube 211 . The flow tube 211 and the fluid through hole 21 share a part of the side wall, and the flow tube 211 and the fluid through hole 21 are integrally formed. The electromagnetic induction coil 8 is preferably arranged on the side wall shared by the flow tube 211 and the fluid through hole 21 . The electrodes 22 are embedded and arranged on opposite side walls of the fluid through hole 21 and / or the flow tube 211 perpendicular to the fluid direction.

[0036] The principle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com